Preparation method of rare-earth permanent magnet, preparation device and rare-earth permanent magnet prepared thereby

A technology for rare earth permanent magnets and preparation devices, which is applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc., and can solve the limitations of diffusion and coercive force enhancement, poor coating bonding force, and corrosion resistance of magnets. To achieve the effect of strong corrosion resistance, improved evaporation efficiency and high coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

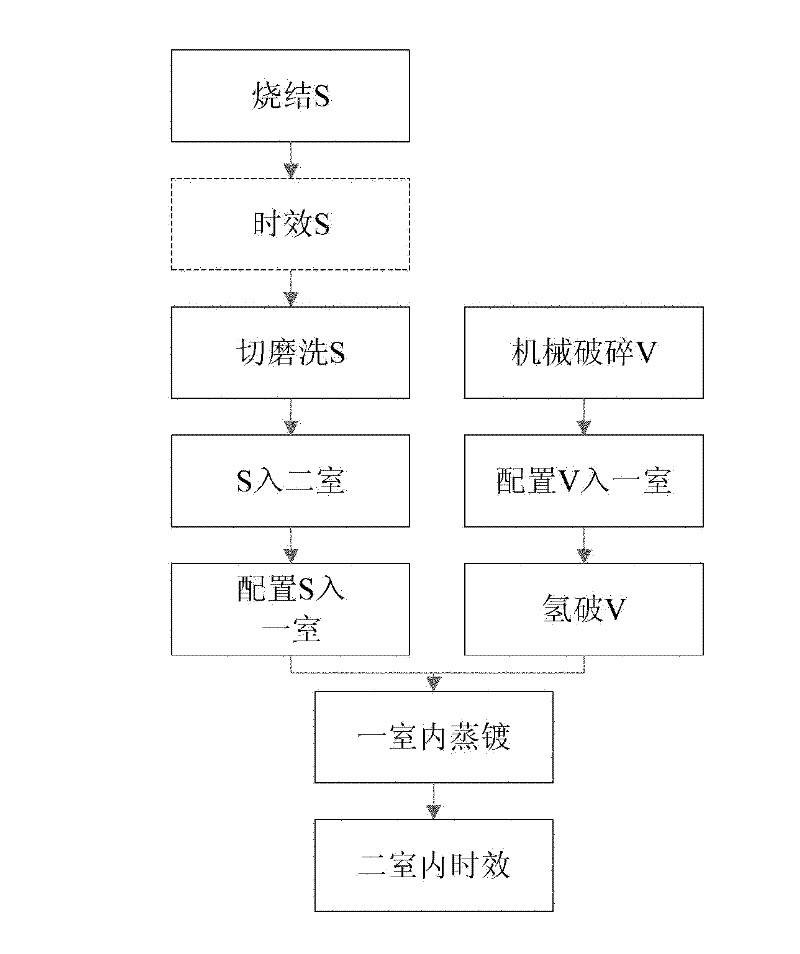

Method used

Image

Examples

preparation example Construction

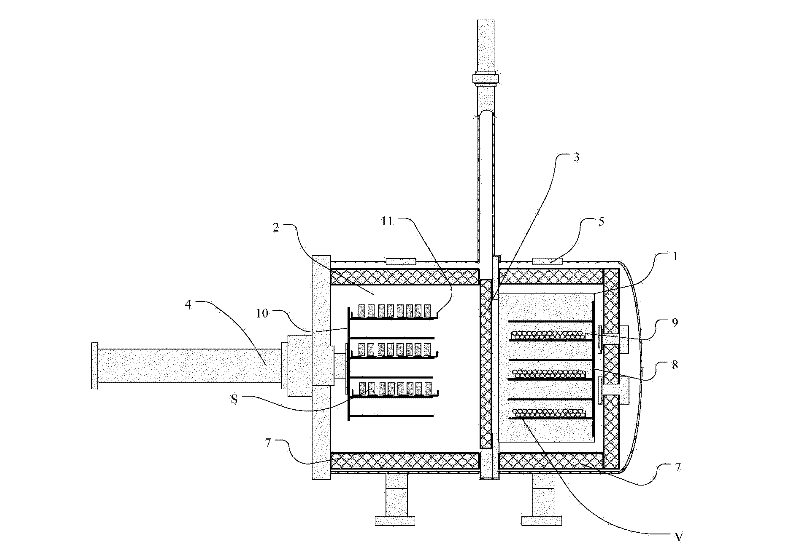

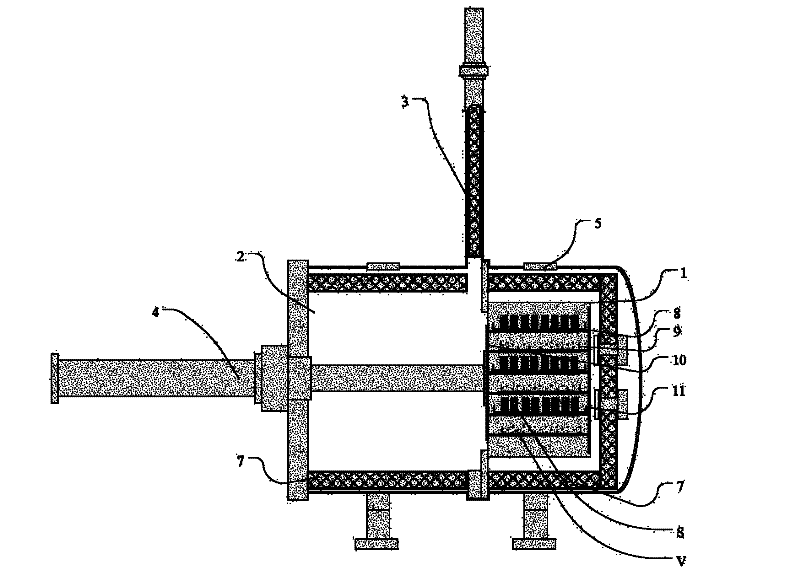

[0060] The preparation device of the rare earth permanent magnet also has a furnace door, a heating device, a heat preservation device, a cooling component and a cooling gas outlet, and a circulating water cooling device, which are common to a vacuum heat treatment device.

[0061] The inner wall of the vacuum chamber, the ventilation pipe, the supporting part A and the carrying device A in the first chamber are all made of materials that do not react with hydrogen and evaporation materials and can withstand high temperatures of at least 1200°C.

[0062] The inner wall of the vacuum in the second chamber, the ventilation pipe, the supporting part B and the supporting device B are all made of materials that do not react with the evaporation material and can withstand high temperatures of at least 1200°C.

[0063] The material of the isolation device does not react with hydrogen, does not react with evaporation materials and can withstand high temperatures of at least 1200°C. Th...

Embodiment 1

[0066] The object to be treated in this embodiment is a sintered permanent magnet (NdPrCeSm) after aging 15 Dy 0.1 co 1.5 B 5.9 Nb 0.5 Ga 0.5 Fe bal (mass percentage), the evaporation material adopts metal Dy. First put the block metal Dy that has been mechanically crushed into an equivalent diameter of 1mm to 30mm into the first chamber for hydrogen crushing. First, the first chamber is evacuated to no more than 10Pa, and then 0.01MPa is introduced into the first chamber. Hydrogen, after the evaporating material absorbs hydrogen sufficiently, heat the first chamber to 500°C and vacuumize to 10 -2 Pa for dehydrogenation treatment, and finally the temperature of the first chamber is lowered to room temperature, and the vacuum degree is kept at 10 -3 Pa, the average particle diameter of the evaporated material after crushing is 500 μm. The magnet to be processed is cut into small square pieces of 12mm×12mm×2mm, take 50 pieces, put them in the second chamber, and evacuate...

Embodiment 2

[0068] The object to be processed in this embodiment is a sintered permanent magnet (NdPrSc) after sintering 15 B 5.8 co 1.0 Fe bal (mass percentage), the evaporation material adopts TbFe alloy. First put the massive TbFe alloy that has been mechanically crushed into an equivalent diameter of 30mm to 100mm into the first chamber for hydrogen crushing. First, the first chamber is evacuated to no more than 10Pa, and then 1.0MPa is introduced into the first chamber. Hydrogen, after the evaporating material absorbs hydrogen sufficiently, heat the first chamber to 650°C and vacuumize to 10 -1 Pa for dehydrogenation treatment, and finally the temperature of the first chamber is lowered to room temperature, and the vacuum degree is kept at 10 -2 Pa, the average particle size of the evaporated material after crushing is 0.1 μm. The magnet to be processed is cut into small square pieces of 12mm×12mm×2mm, take 50 pieces, put them in the second chamber, and evacuate the second chamb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com