Composite membrane for packing biological medicines

A biomedicine and composite film technology, applied in the field of composite film for biomedical packaging, can solve the problems of composite film burnout, poor high temperature resistance, and inability to achieve disinfection effect, and achieves high temperature burnout prevention, excellent barrier performance, good The effect of market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings and examples. The embodiments of the present invention include but are not limited to the following examples.

[0020] Embodiment: in order to realize the above object, the technical scheme adopted in the present invention is as follows:

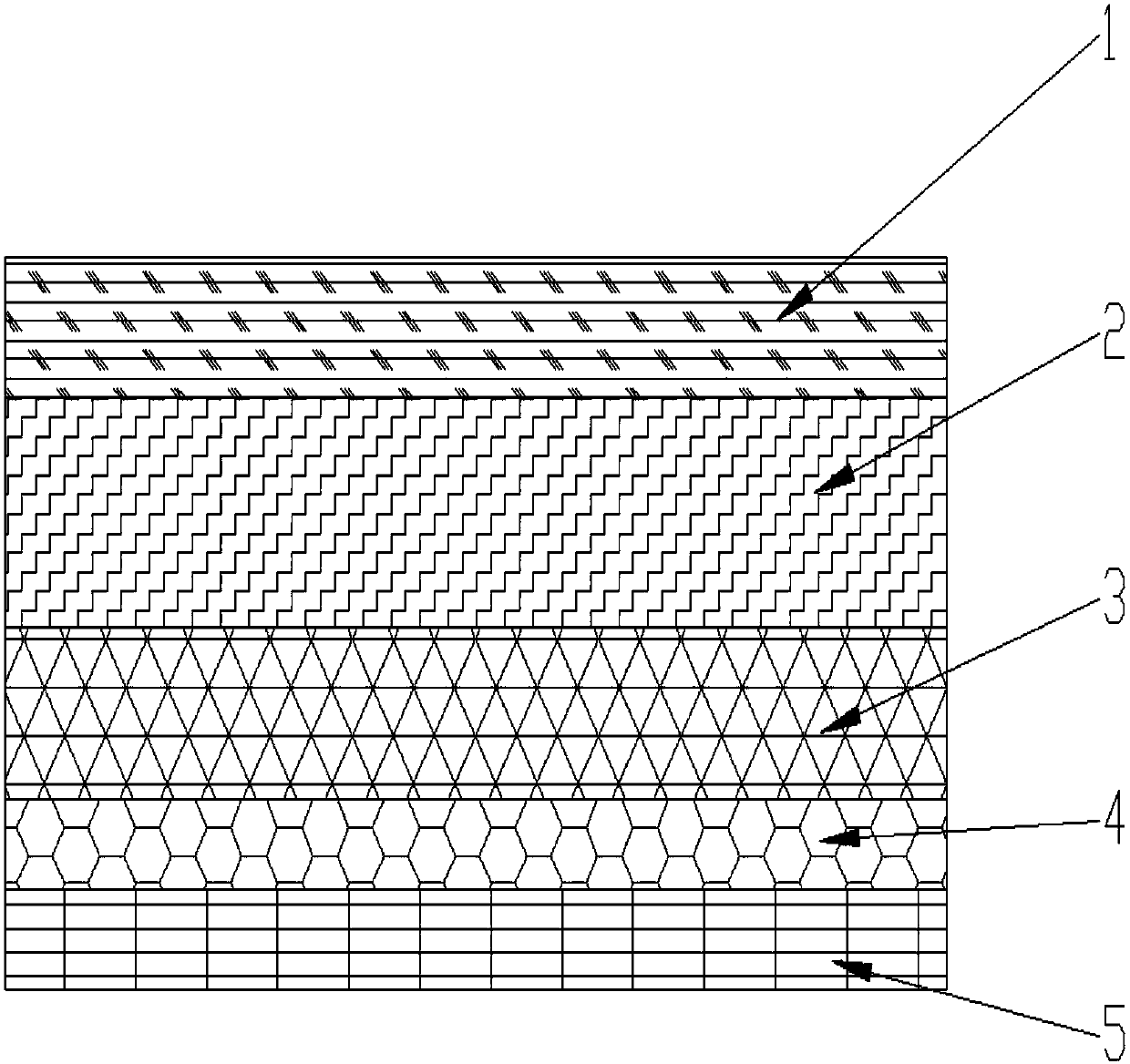

[0021] like figure 1 As shown, the present invention provides a composite film for biomedical packaging, CPP layer 1, aluminum foil layer 2, PET layer 3, polyurethane adhesive layer 4 and antibacterial layer 5, CPP layer 1, aluminum foil layer 2, PET layer 3. The polyurethane adhesive layer 4 and the antibacterial layer 5 are adjacently connected together from top to bottom.

[0022] The present invention further provides that: the antibacterial layer 5 is a nano-silver layer, and its thickness is between 0.5 microns and 0.9 microns.

[0023] The present invention further provides that: the thickness of the aluminum foil layer 2 is betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com