Water-based ceramic slurry, preparation method of ceramic film and chip multilayer ceramic capacitor

A technology of ceramic slurry and ceramic film, applied in capacitors, fixed capacitors, fixed capacitor dielectrics, etc., can solve the problems of poor quality of cast film, and achieve the effect of small film thickness, good mechanical properties and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0040] As an embodiment, based on 100 parts of the total weight of the water-based ceramic slurry, the water-based ceramic slurry includes the following components in parts by weight:

[0041]

[0042] Wherein, the pH of the water-based ceramic slurry is 8.

[0043] The cast film with a film thickness of 9.5 μm can be obtained after casting the above water-based ceramic slurry, the surface of the film layer is smooth and dense, and the comprehensive performance is optimal.

[0044] The calculation formula of MLCC capacitance is C=ε×S×(N-1) / d, where ε is the dielectric constant of the dielectric (F / M); S is the area of the internal electrode (m 2 ); N is the number of dielectric layers; d is the thickness (m) of the dielectric layer. It can be seen that the thickness of the dielectric layer is the limiting factor restricting the capacitance performance of MLCC. The thickness of the casting film obtained by casting the above ceramic slurry is less than 10 microns, which me...

Embodiment 1

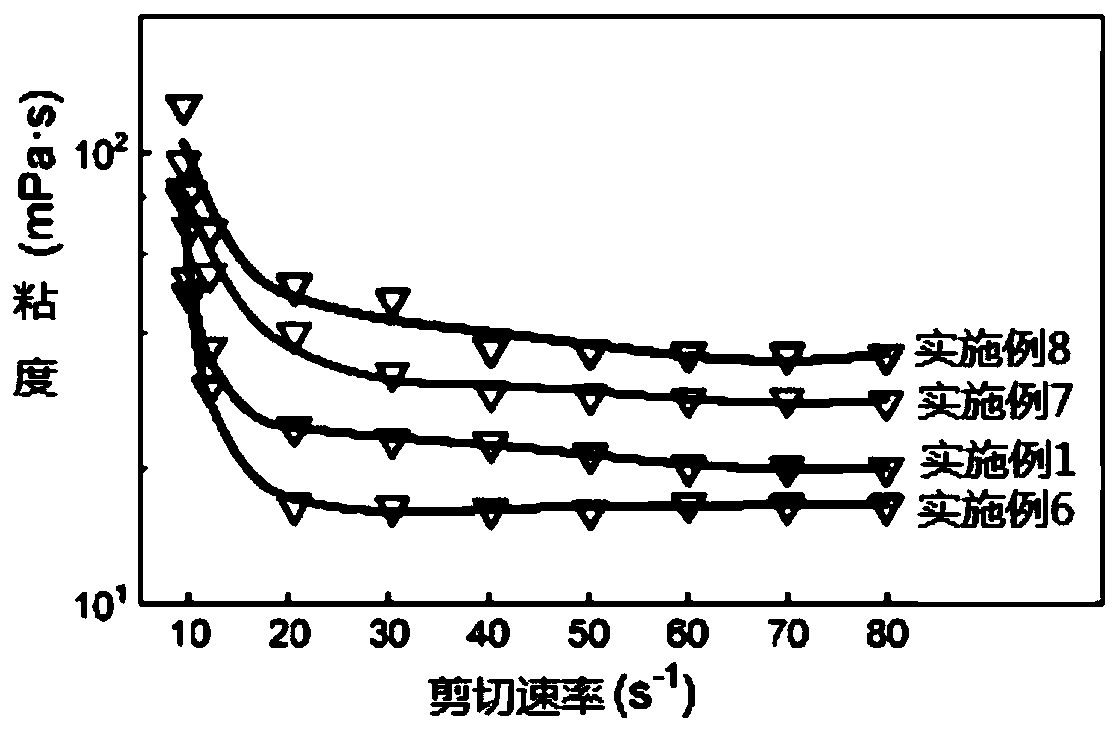

[0092] This embodiment provides a kind of ceramic thin film for preparing MLCC, and the preparation method of this ceramic thin film specifically comprises the following steps:

[0093] S11, providing ceramic slurry;

[0094] (1) Prepare materials according to the following slurry formula:

[0095]

[0096] Wherein, the pH of the ceramic slurry is 8.

[0097] (2) Preparation of slurry

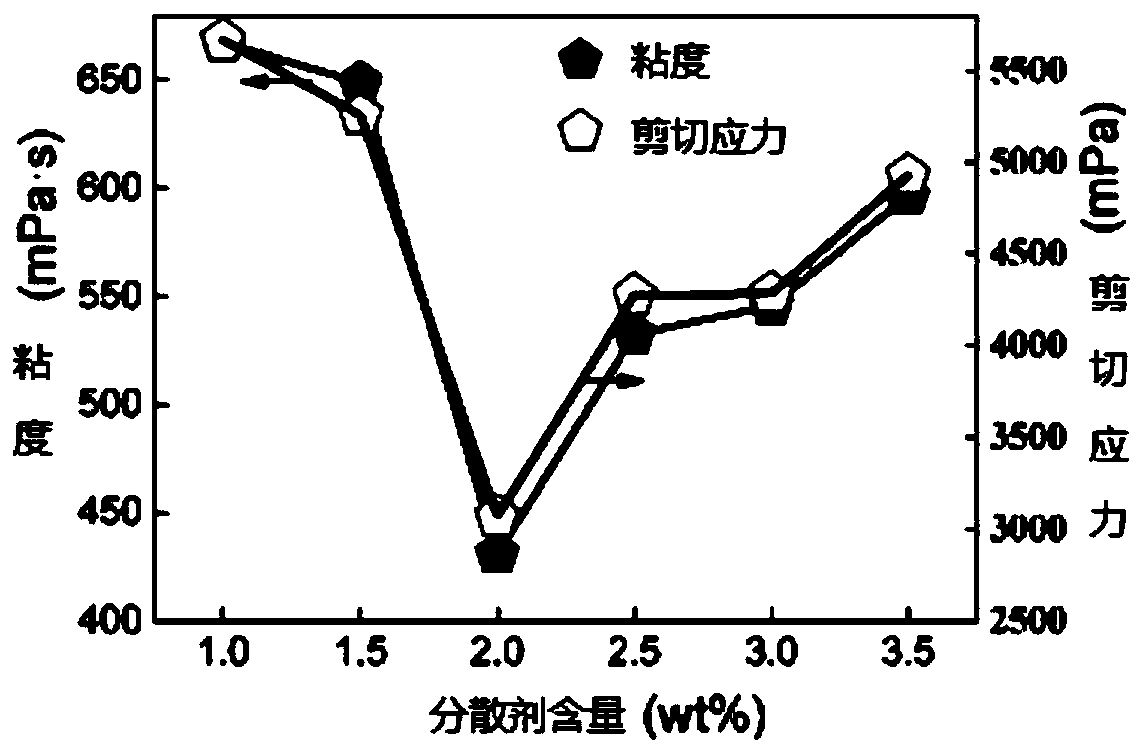

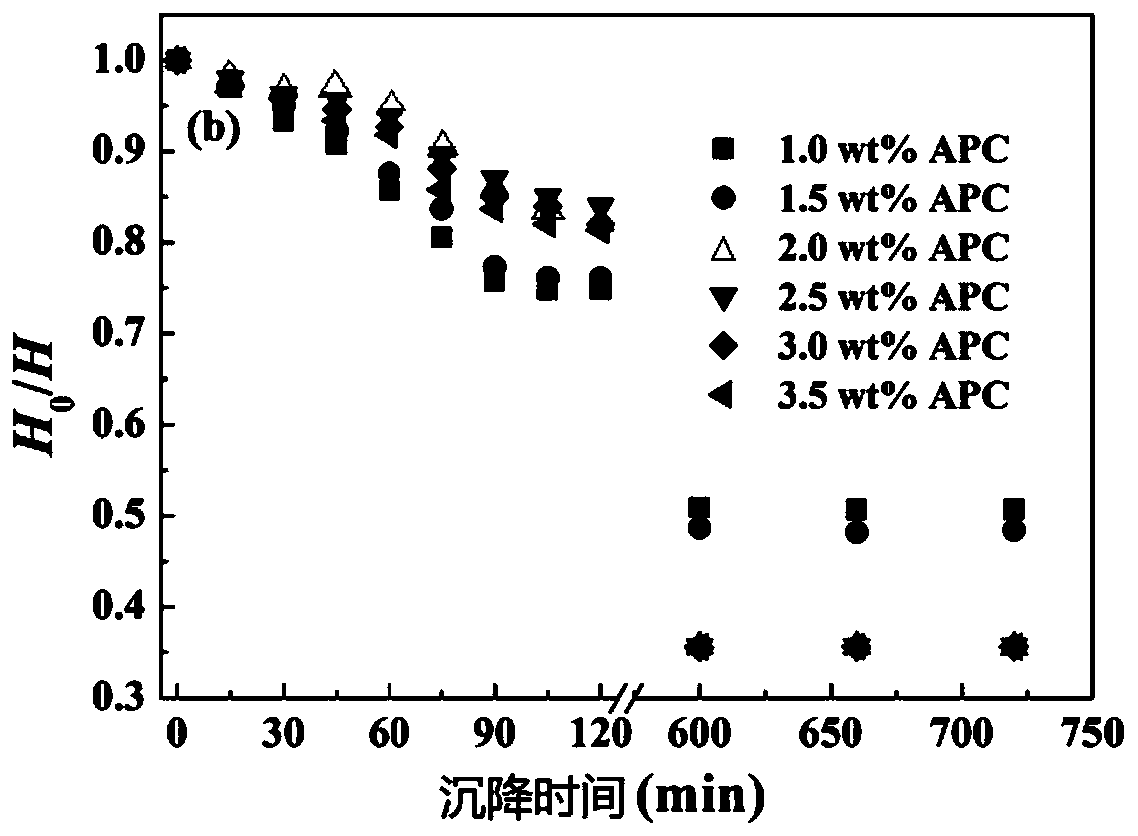

[0098] Mix barium titanate powder, APC and deionized water, ball mill for 4 hours, use HCl and NH 3 ·H 2 O adjusts the pH value to 8 to obtain the first mixture;

[0099] Polyacrylate, di-n-butyl phthalate and the first mixture were mixed, ball milled for 5 hours and then vacuum degassed for 40 minutes to obtain a ceramic slurry.

[0100] S12. Use a casting machine (BHLY-011A, Beijing Oriental Sun Technology Co., Ltd., China) to prepare a ceramic film, adjust the height of the scraper to 50 microns, the casting line speed to 0.25cm / s, the drying temperature to 40°C, and the drying time ...

Embodiment 21

[0106] This embodiment provides an MLCC, comprising: cutting the ceramic thin film prepared in Step S12 of Embodiment 1 into square sheets of 10mm×10mm, and the number of square sheets is 30; using platinum paste (5570Pt, ESL, USA ) to screen-print the square sheet layer by layer, then stack and laminate (30 layers) at 70 °C and 8 MPa for 0.5 h; finally, perform pressureless sintering at 1100 °C for 0.5 h to obtain dense BaTiO 3 Base MLCC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com