Recycled engineering plastic assembled pavement and paving method thereof

A technology of recycled plastics and engineering plastics, applied to roads, roads, pavement details, etc., can solve the problems of broken pavement panel integrity, large shear stress, and reduced service life of pavement panels, so as to reduce self-weight and construction difficulty, The structure has a large hollow volume and the effect of reducing the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The honeycomb recycled plastic panel 6 is composed of 65 parts of waste plastic, 25 parts of filler, 20 parts of glass fiber, 7 parts of flame retardant, 4 parts of coupling agent and 2 parts of lubricant. Among them, the filler is made of 40% It is made of quartz powder, 40% talc powder and 20% mica powder.

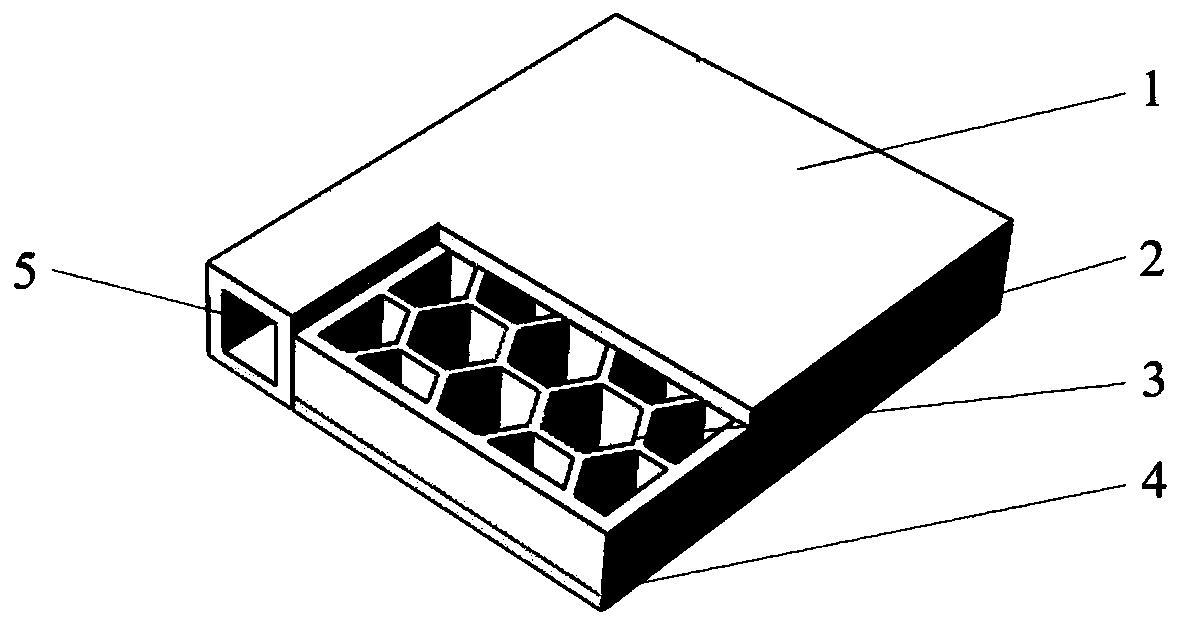

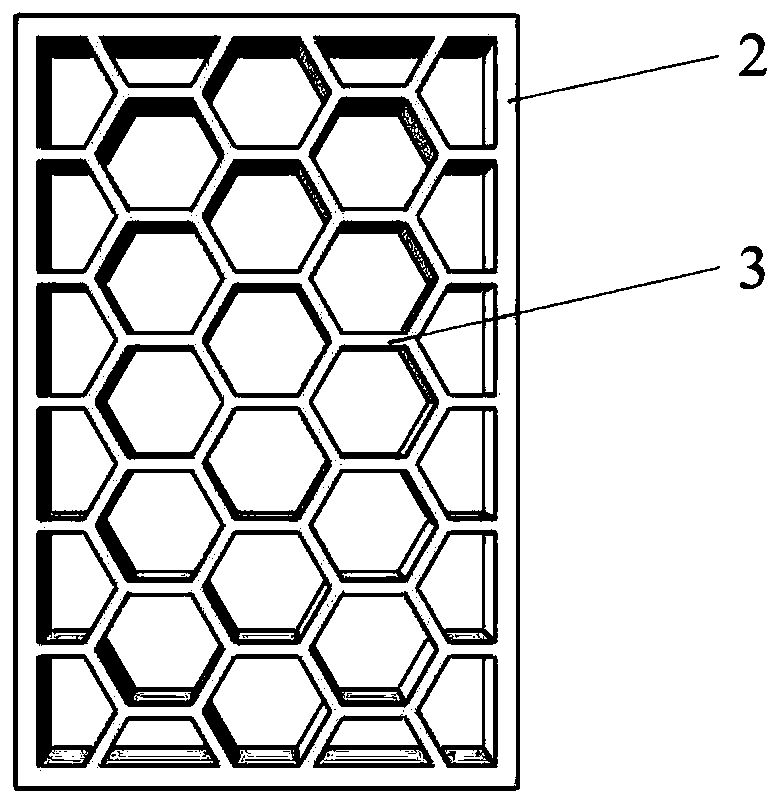

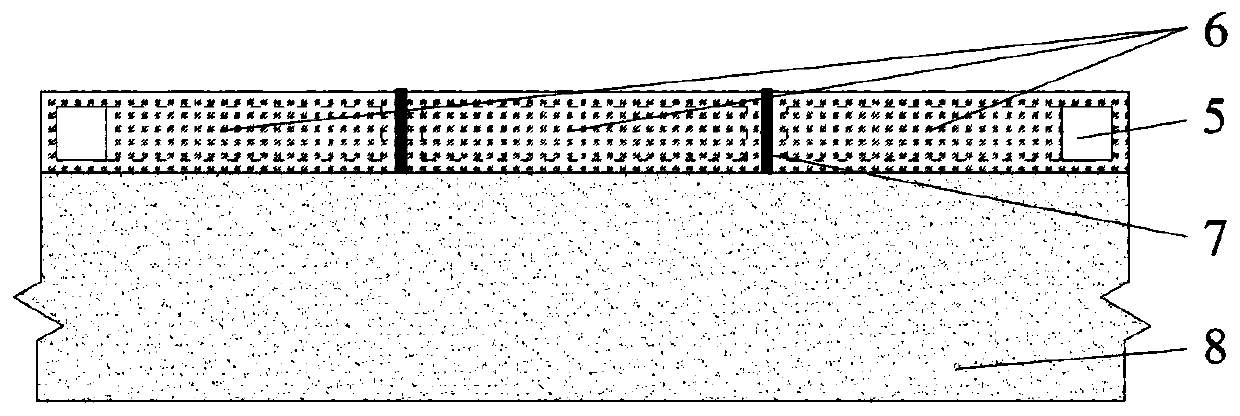

[0044] The elastic modulus of the honeycomb recycled plastic panel 6 is 3500MPa, and the water permeability coefficient of the cover plate 1 is 10 -2 cm / s, the honeycomb core plate is composed of ribs 3 spliced into units with a regular hexagonal cross section, the thickness of the cover plate 1 is 10cm, the length of the ribs 3 is 30cm, and the thickness is 5cm, The thickness of the side plate 2 is 8 cm, the thickness of the bottom plate 4 is 8 cm; the width of the anti-skid groove on the upper surface of the cover plate 1 is 4 mm, the groove depth is 8 mm, and the distance between the anti-skid grooves along the width direction is 16 cm. The underground water...

Embodiment 2

[0046] The honeycomb recycled plastic panel 6 is composed of 70 parts of waste plastic, 30 parts of filler, 25 parts of glass fiber, 10 parts of flame retardant, 7 parts of coupling agent, and 4 parts of lubricant. Among them, the filler is made of 50% It is made of quartz powder, 30% talc powder and 20% mica powder.

[0047] The elastic modulus of the honeycomb recycled plastic panel 6 is 3000MPa, and the water permeability coefficient of the cover plate 1 is 10 -2 cm / s, the honeycomb core plate is formed by splicing the ribs 3 into units with a regular pentagon in cross section, the thickness of the cover plate 1 is 12cm, the length of the ribs 3 is 40cm, and the thickness is 6cm, The thickness of the side plate 2 is 10cm, the thickness of the bottom plate 4 is 10cm; the width of the anti-skid groove on the upper surface of the cover plate 1 is 5mm, the groove depth is 10mm, and the distance between the anti-skid grooves along the width direction is 20cm. The underground wa...

Embodiment 3

[0049] The honeycomb recycled plastic panel 6 is composed of 60 parts of waste plastic, 20 parts of filler, 15 parts of glass fiber, 5 parts of flame retardant, 3 parts of coupling agent and 1 part of lubricant. Among them, the filler is made of 50% It is made of talcum powder and 50% mica powder.

[0050] The elastic modulus of the honeycomb recycled plastic panel 6 is 2500MPa, and the water permeability coefficient of the cover plate 1 is 10 -2 cm / s, the honeycomb core plate is formed by splicing the ribs 3 into units with a regular hexagonal cross section, the thickness of the cover plate 1 is 8cm, the length of the ribs 3 is 20cm, and the thickness is 3cm. The thickness of the plate 2 is 6cm, the thickness of the bottom plate 4 is 6cm; the groove width of the anti-skid groove on the upper surface of the cover plate 1 is 3mm, the groove depth is 6mm, and the distance between the anti-skid grooves along the width direction is 15cm.

[0051] A pipeline channel 5 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com