Cathodic protection system of wet desulfurized funnel

A wet desulfurization and cathodic protection technology, applied in the field of cathodic protection system, can solve the problems of poor temperature shock resistance, easy cracks, cracks or peeling, etc., and achieve excellent acid resistance, less cracks and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

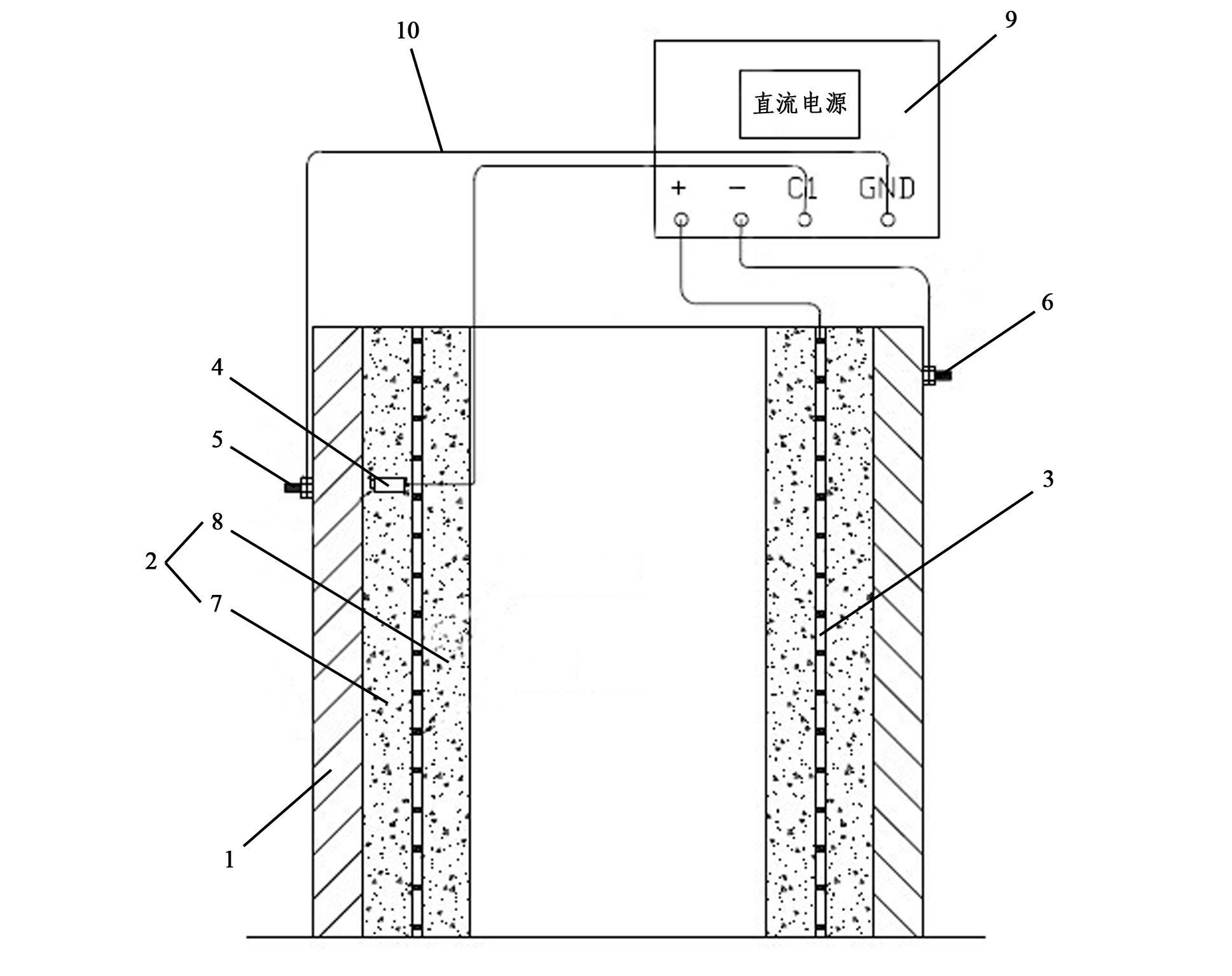

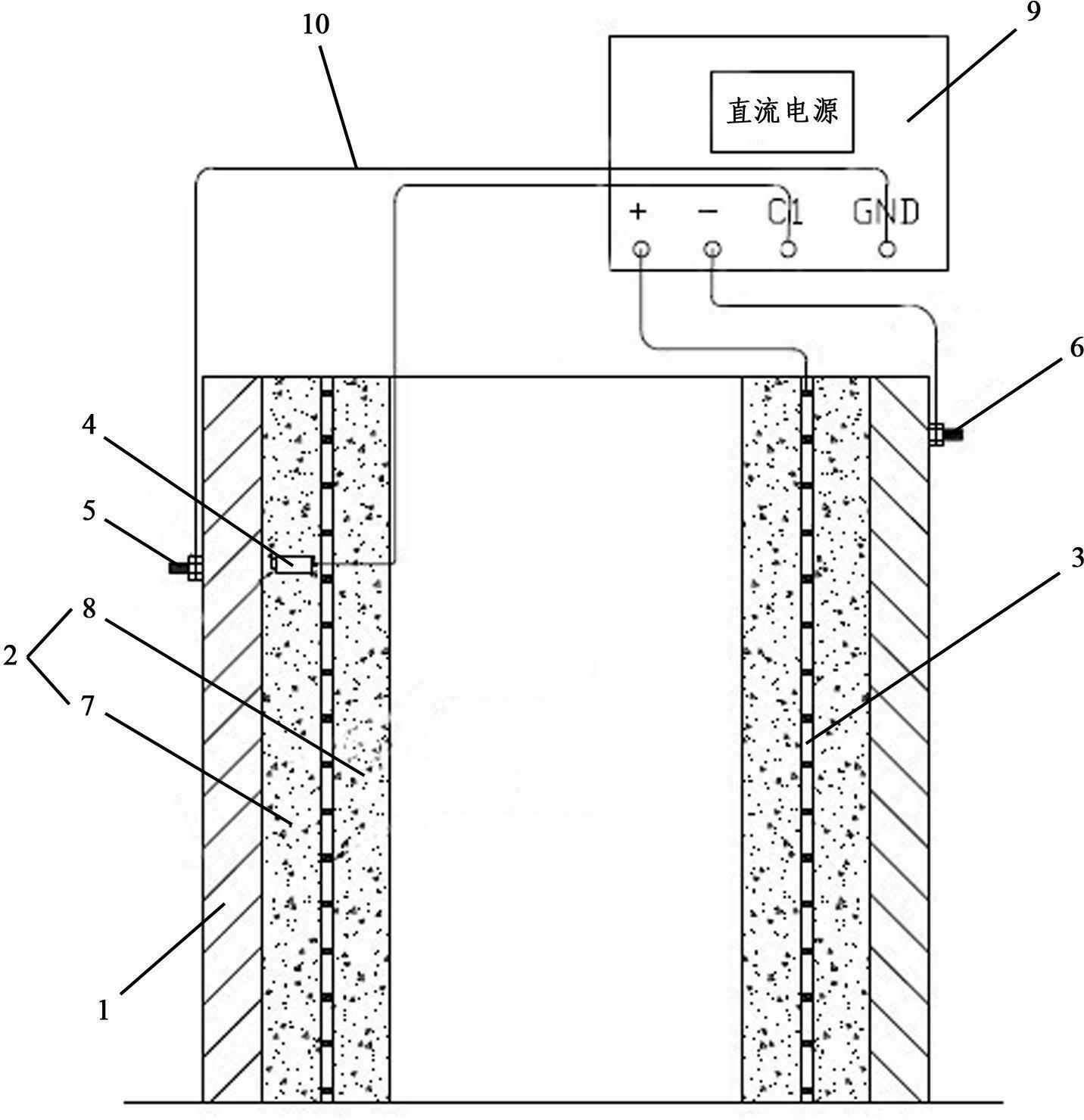

[0024] Embodiment one: see attached figure 1 shown.

[0025] A cathodic protection system for a wet desulfurization chimney is used for controlling corrosion of a wet desulfurization chimney in a thermal power plant. The wet desulfurization chimney includes a base body 1 that encloses a flue, and the base body 1 is built by a concrete cylinder or a steel inner cylinder is set on the basis of the concrete cylinder. The base body 1 has an inner wall and an outer wall, and the end of the base body 1 forms an outlet of a wet desulfurization chimney.

[0026] The cathodic protection system of the wet desulfurization chimney includes an acid-resistant layer 2 arranged along the inner wall, an anode grid 3 laid in the acid-resistant layer 2, a reference electrode 4 embedded in the acid-resistant layer 2, and an outer wall of the wet desulfurization chimney. The measurement grounding device 5 and cathode 6, potentiostat. The anode net 3 covers the entire inner wall of the wet desul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com