Partition-optimized ultrathin VC with thickness of 0.1-0.4 mm and preparation method

A partition-optimized, ultra-thin technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as increased interface shear force, reduced heat pipe thickness, low water resistance, thermal resistance, etc., to reduce vapor resistance , Reduce liquid flow resistance, reduce the effect of water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

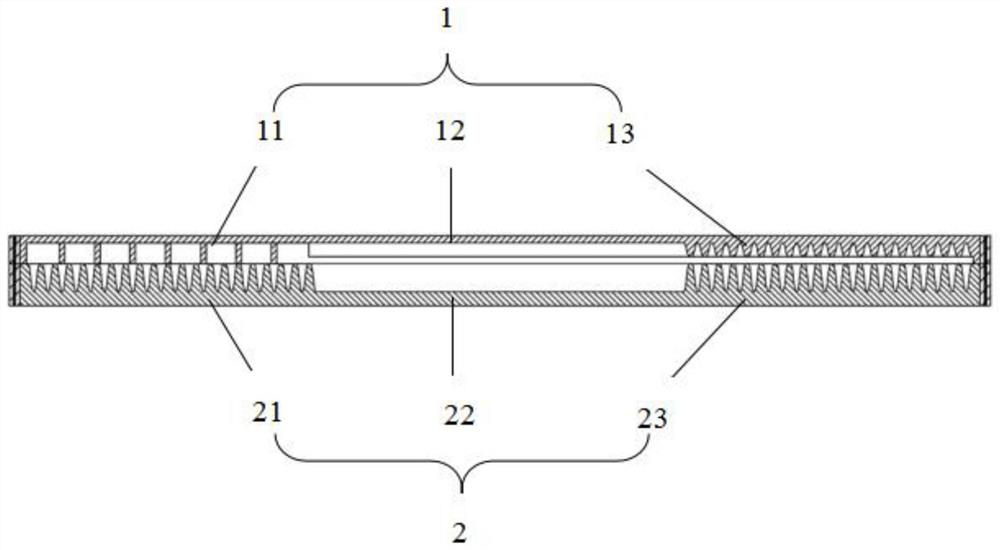

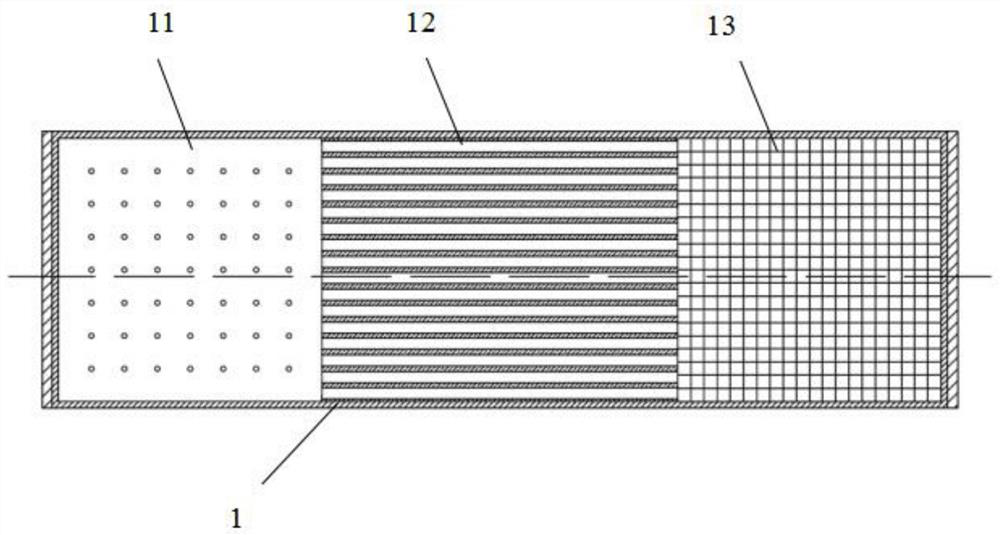

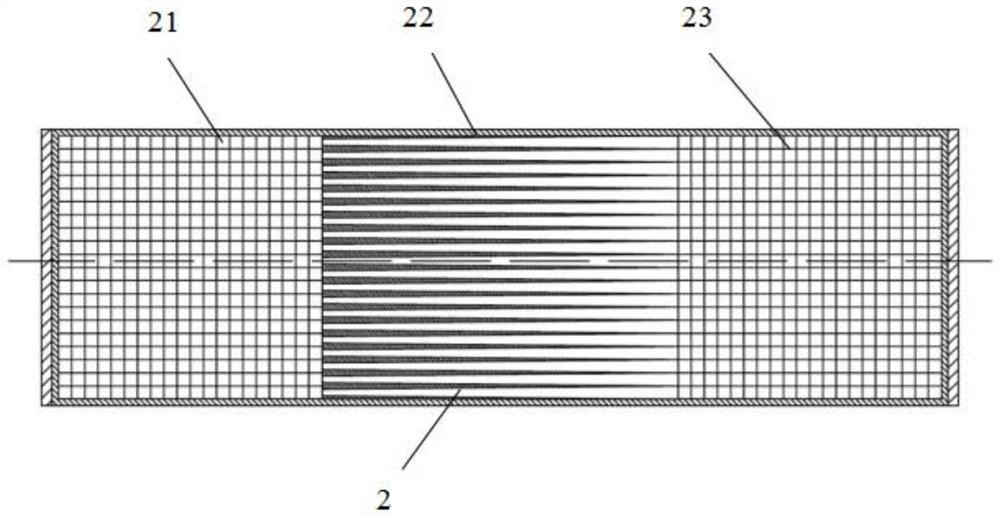

[0041] A 0.1-0.4mm ultra-thin VC optimized for partitioning, including an upper cover 1 and a lower cover 2, the upper cover 1 and the lower cover 2 are connected by laser welding; the upper cover 1 includes a first evaporation section 11, a second An adiabatic section 12 and a first condensing section 13; the area surface of the first evaporation section 11 is set as a super-hydrophilic cavity-shaped micro-nano structure; the area surface of the first adiabatic section 12 is set as a super-hydrophilic equal-width groove micro-nano structure; The area surface of the first condensation section 13 is set to a superhydrophobic conical micro-nano structure; the lower cover plate 2 includes a second evaporation section 21, a second adiabatic section 22 and a second condensation section 23; the area surface of the second evaporation section 21 is set to Superhydrophilic conical micro-nano structure; the surface of the second thermal insulation section 22 is set as a super-hydrophilic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com