High-strength alkali-inhibiting construction waste regenerated water permeable brick and preparation method thereof

A technology of construction waste and permeable bricks, applied in the field of building materials, can solve the problems of poor mechanical properties of recycled aggregates, low strength of recycled permeable bricks, high alkalinity, etc., to improve performance and service life, good pan-alkali resistance, Strong water absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

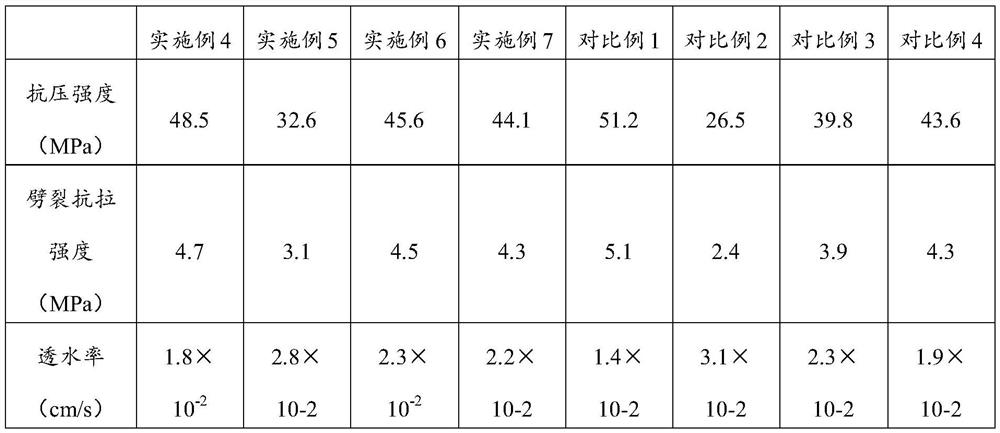

Examples

Embodiment 1

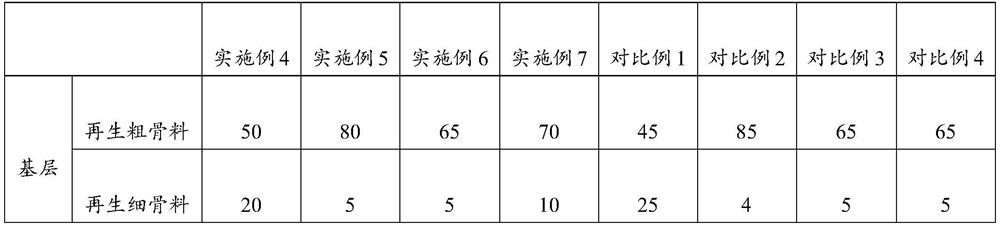

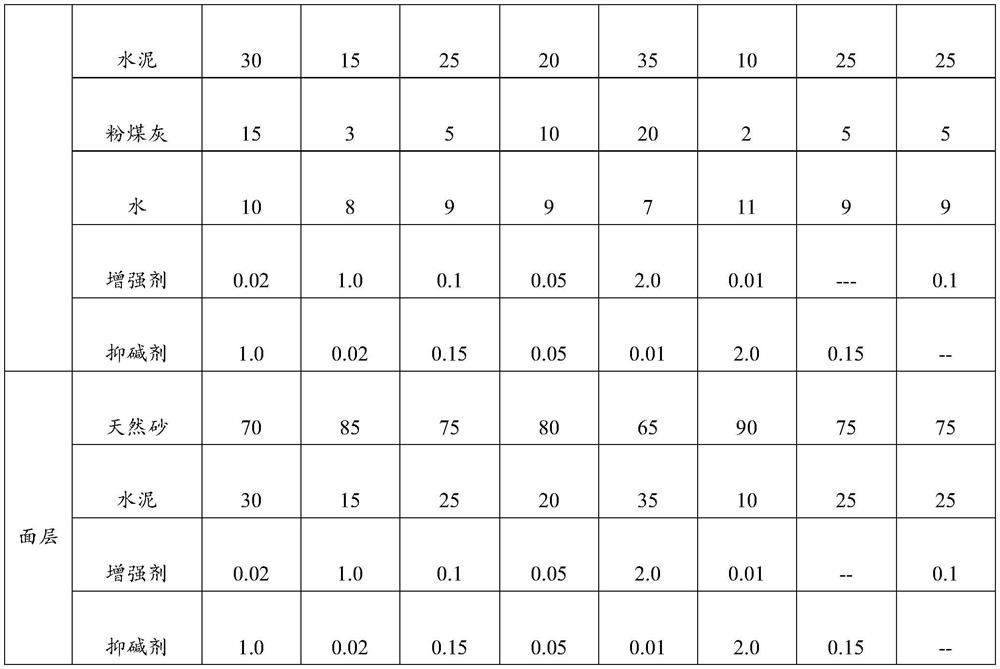

[0028] A high-strength anti-alkali construction waste recycled permeable brick, the permeable brick includes a base layer and a surface layer, and the base layer includes the following raw material components in parts by weight: 55 parts of recycled coarse aggregate from construction waste, 20 parts of recycled fine aggregate from construction waste , 25 parts of cement, 15 parts of fly ash, 10 parts of water, 0.02 part of reinforcing agent, 1.0 part of alkali suppressant, the surface layer includes the following raw material components in parts by weight: 75 parts of natural sand, 25 parts of cement, reinforcing agent 0.02 parts, 1.0 parts of base inhibitor.

[0029] The regenerated coarse aggregate of construction waste in this embodiment is the aggregate obtained by crushing and screening construction waste with a particle size of 5-10 mm, and the regenerated fine aggregate of construction waste is the particle size obtained after crushing and screening of construction waste...

Embodiment 2

[0036] A high-strength anti-alkali construction waste recycled permeable brick, the permeable brick includes a base layer and a surface layer, and the base layer includes the following raw material components in parts by weight: 60 parts of recycled coarse aggregate from construction waste, 5 parts of recycled fine aggregate from construction waste , 28 parts of cement, 3 parts of fly ash, 8 parts of water, 1.0 part of reinforcing agent, 0.02 part of alkali suppressant, described surface layer comprises the raw material component of following weight part: 72 parts of natural sand, 22 parts of cement, strengthening agent 1.0 part, 0.02 part of base inhibitor.

[0037]The regenerated coarse aggregate of construction waste in this embodiment is the aggregate obtained by crushing and screening construction waste with a particle size of 5-10 mm, and the regenerated fine aggregate of construction waste is the particle size obtained after crushing and screening of construction waste w...

Embodiment 3

[0041] A high-strength anti-alkali construction waste recycled permeable brick, the permeable brick includes a base layer and a surface layer, and the base layer includes the following raw material components in parts by weight: 77 parts of recycled coarse aggregate from construction waste, 15 parts of recycled fine aggregate from construction waste , 20 parts of cement, 5 parts of fly ash, 9 parts of water, 0.5 part of reinforcing agent, 0.5 part of alkali inhibitor, and described surface layer comprises the raw material component of following weight part: 80 parts of natural sand, 20 parts of cement, strengthening agent 0.5 parts, alkali inhibitor 0.5 parts.

[0042] The regenerated coarse aggregate of construction waste in this embodiment is the aggregate obtained by crushing and screening construction waste with a particle size of 5-10 mm, and the regenerated fine aggregate of construction waste is the particle size obtained after crushing and screening of construction wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com