Inorganic heat-insulation fireproof plate

A technology of fire-proof insulation board and board, which is applied in the direction of heat preservation, fire prevention, and construction material processing, etc. It can solve the problems of high water absorption, large volume shrinkage, hollowing and cracking of expanded perlite, and improve the comprehensive performance and construction performance. , Overcoming the effect of high water absorption and improving flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

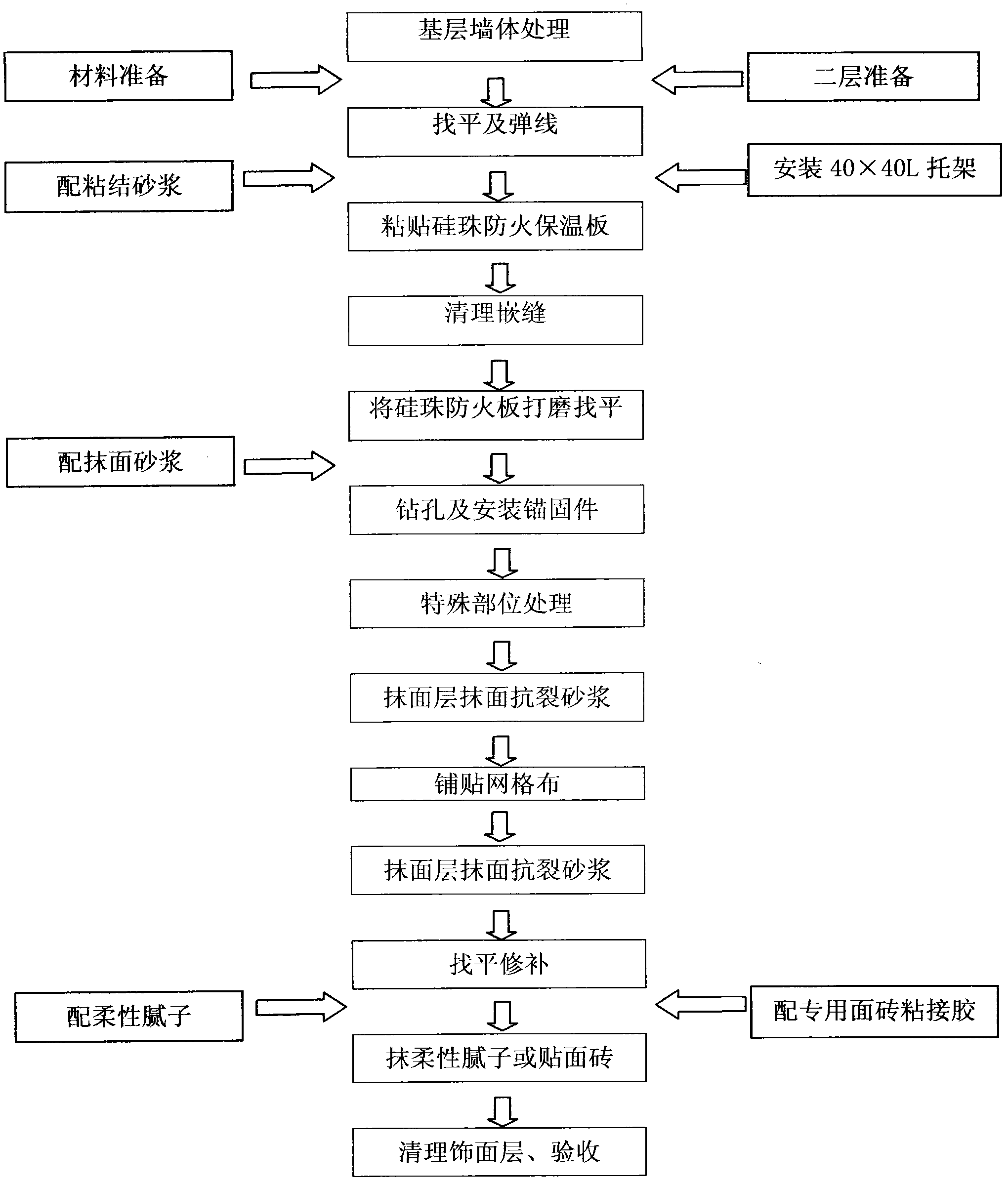

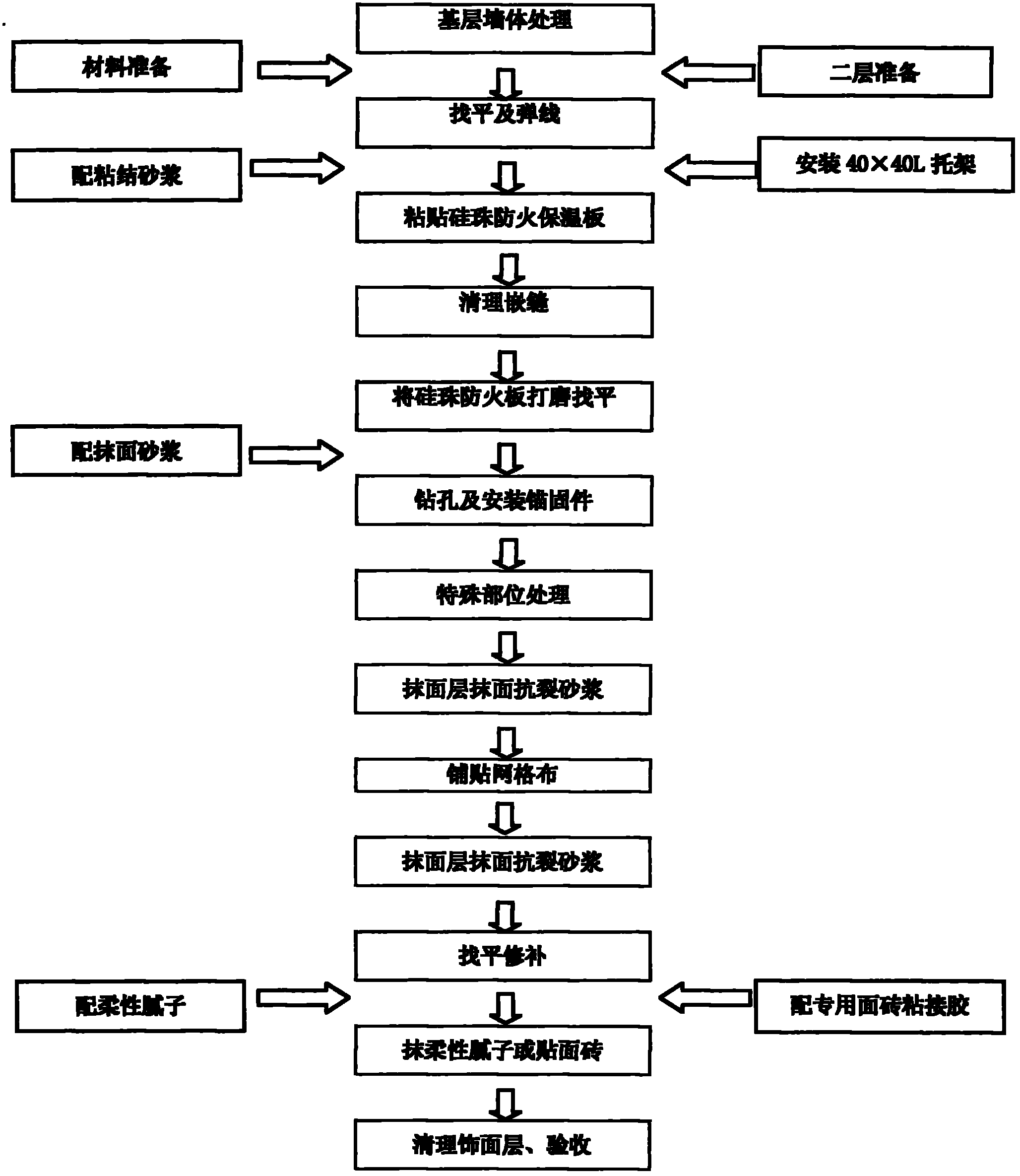

Method used

Image

Examples

no. 1 Embodiment

[0015] The first specific embodiment of the present invention is an inorganic thermal insulation and fireproof board. The fireproof board is composed of hydrophobic vitrified microspheres and xonotlite, wherein the proportion of vitrified microspheres and xonotlite is 1 by weight. : 2, in addition, add 2% waterproof material and 8% gel material in total weight.

no. 2 Embodiment

[0016] The second specific embodiment of the present invention is an inorganic thermal insulation fireproof board, said fireproof board is composed of hydrophobic vitrified microspheres and xonotlite, wherein the proportion of vitrified microspheres and xonotlite is 1 : 3. In addition, 3% of the total weight of the waterproof material and 9% of the gel material are added.

no. 3 Embodiment

[0017] The third specific embodiment of the present invention is an inorganic heat-preservation and fireproof board. The fireproof board is composed of hydrophobic vitrified microspheres and xonotlite, wherein the proportion of vitrified microspheres and xonotlite is 1 by weight. : 4.5, in addition, add 4% waterproof material of total weight, 10% gel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com