High-strength and high-toughness geopolymer material and preparation method thereof

A geopolymer, high-strength and high-toughness technology, applied in the direction of cement production, etc., can solve the problems of limited application and development, large shrinkage, strong brittleness, etc., achieve excellent mechanical strength, small early shrinkage, and improve fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

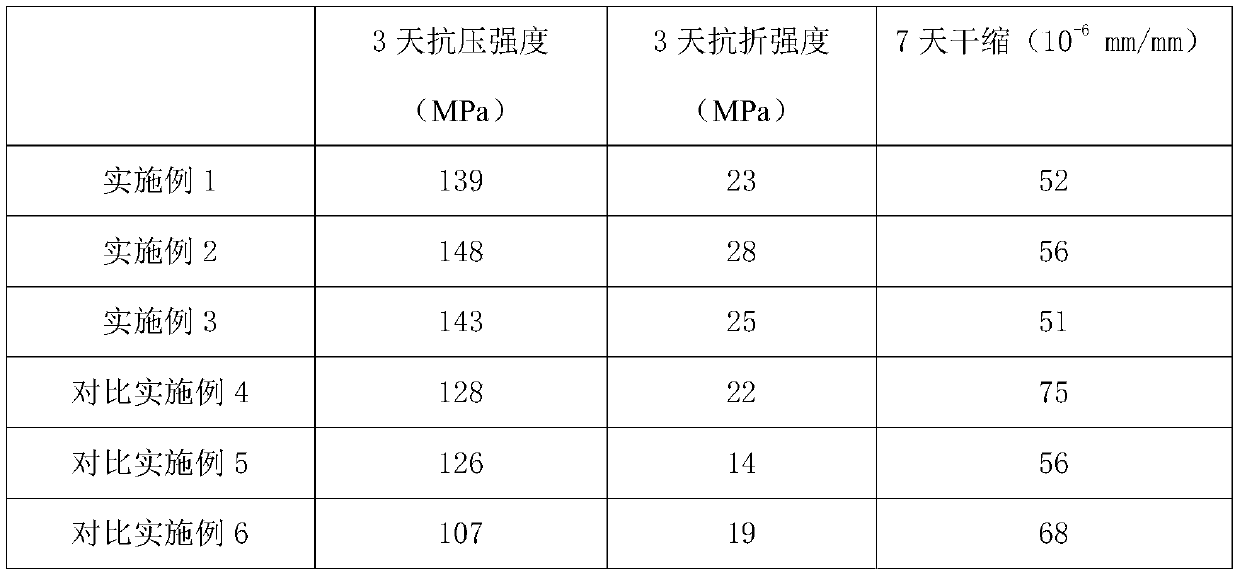

Examples

Embodiment 1

[0021] 1) 200g of metakaolin, 150g of fly ash, 50g of red mud, 40g of slag, 40g of silica fume and 20g of Portland cement were mixed, stirred and ground in proportion to obtain a silica-alumina mineral raw material;

[0022] 2) 20g of condensed phosphate, 20g of nano-silicon dioxide, 20g of nano-alumina, and 10g of zeolite are mixed and ground in proportion to obtain a nano-scale high-efficiency modifier;

[0023] 3) Put 2g of superabsorbent resin into 100g of deionized water and let it stand for 10 minutes to obtain a pre-absorbent superabsorbent resin:

[0024] 4) Pour 50g of sodium hydroxide into 600g of liquid sodium silicate in proportion, stir evenly, cool and stand at room temperature for 24 hours to obtain an alkali activator;

[0025] 5) 1g of 5mm long chopped carbon fiber, 1g of 5mm long polypropylene fiber, 1g of 5mm long chopped basalt fiber, 3g of calcium lignosulfonate, 1g of sodium lauryl sulfate are mixed with the alkali activator obtained in step 4) , 50Hz ul...

Embodiment 2

[0028] 1) 300g of metakaolin, 200g of fly ash, 50g of red mud, 50g of slag, 60g of silica fume and 40g of Portland cement were mixed, stirred and ground in proportion to obtain a silica-alumina mineral raw material;

[0029] 2) 50g of condensed phosphate, 40g of nano-silicon dioxide, 40g of nano-alumina, and 20g of zeolite were mixed and ground in proportion to obtain a nano-scale high-efficiency modifier;

[0030] 3) Put 3g of superabsorbent resin into 150g of deionized water and let it stand for 15 minutes to obtain a pre-absorbed superabsorbent resin:

[0031] 4) Pour 130g of sodium hydroxide into 650g of liquid sodium silicate in proportion, stir evenly, cool and stand at room temperature for 24 hours to obtain an alkali activator;

[0032] 5) 3g 5mm long chopped carbon fiber, 2g 5mm long polypropylene fiber, 1g 5mm long chopped basalt fiber, 5g calcium lignosulfonate, 5g sodium lauryl sulfate are mixed with the alkali activator obtained in step 4) , 50Hz ultrasonic dispe...

Embodiment 3

[0035] 1) 250g of metakaolin, 180g of fly ash, 70g of red mud, 50g of slag, 50g of silica fume and 30g of Portland cement were mixed, stirred and ground in proportion to obtain a silica-alumina mineral raw material;

[0036]2) 35g of condensed phosphate, 30g of nano-silicon dioxide, 30g of nano-alumina, and 15g of zeolite were mixed and ground in proportion to obtain a nano-scale high-efficiency modifier;

[0037] 3) Put 4g of superabsorbent resin into 150g of deionized water and let it stand for 20 minutes to obtain a pre-absorbed superabsorbent resin:

[0038] 4) Pour 100g of sodium hydroxide into 650g of liquid sodium silicate in proportion, stir evenly, cool and stand at room temperature for 24 hours to obtain an alkali activator;

[0039] 5) 2g 5mm long chopped carbon fiber, 1.5g 5mm long polypropylene fiber, 1g 5mm long chopped basalt fiber, 3g calcium lignosulfonate, 3g sodium lauryl sulfate and step 4) obtained alkali activator Mixing, 50Hz ultrasonic dispersion for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com