Quantitative determining device for saturated surface dry state of fine aggregates and method thereof

A technology for determining devices and methods, applied to measuring devices, analysis materials, instruments, etc., can solve the problems of not being well applicable to different types of fine aggregates, no quantitative judgment indicators, human factors, etc., to avoid errors , Overcoming poor applicability and avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

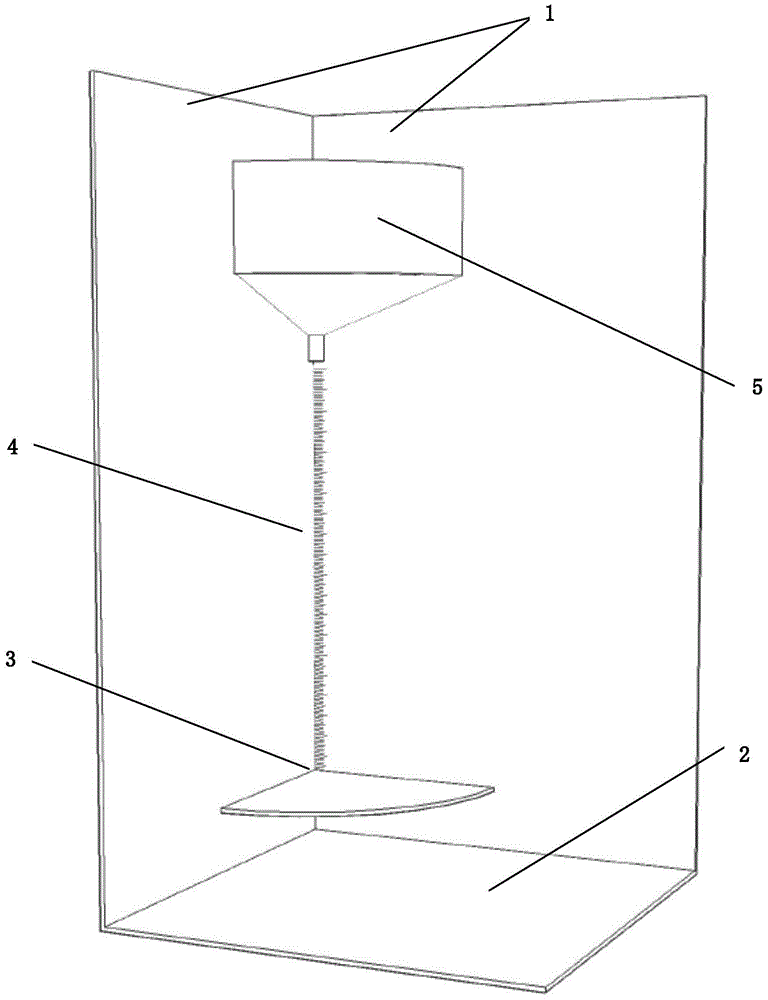

[0040] like figure 1A quantitative determination tool for the dry state of the fine aggregate saturated surface is shown, including a back plate 1, a bottom plate 2, a cap 3, a scale 4 and a funnel 5, two back plates 1 and a bottom plate 2 are perpendicular to each other, and the cap 3 It is fan-shaped, and its fan-shaped surface is parallel to the surface of the bottom plate 2, and is higher than the bottom plate 2 and is vertically fixed on the two back plates 1. On the intersection line, and starting from the intersection point between the upper surface of the platform 3 and the two backboards 1, the funnel 5 is located above the maximum scale of the scale 4 and fixed on the two backboards 1 On top, a switch is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com