Deductive method of hardened concrete mixing ratio

A concrete and mix ratio technology, applied in the field of material engineering, can solve the problems of inapplicability, inability to obtain the proportion of coarse and fine aggregate in concrete, and complicated measurement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

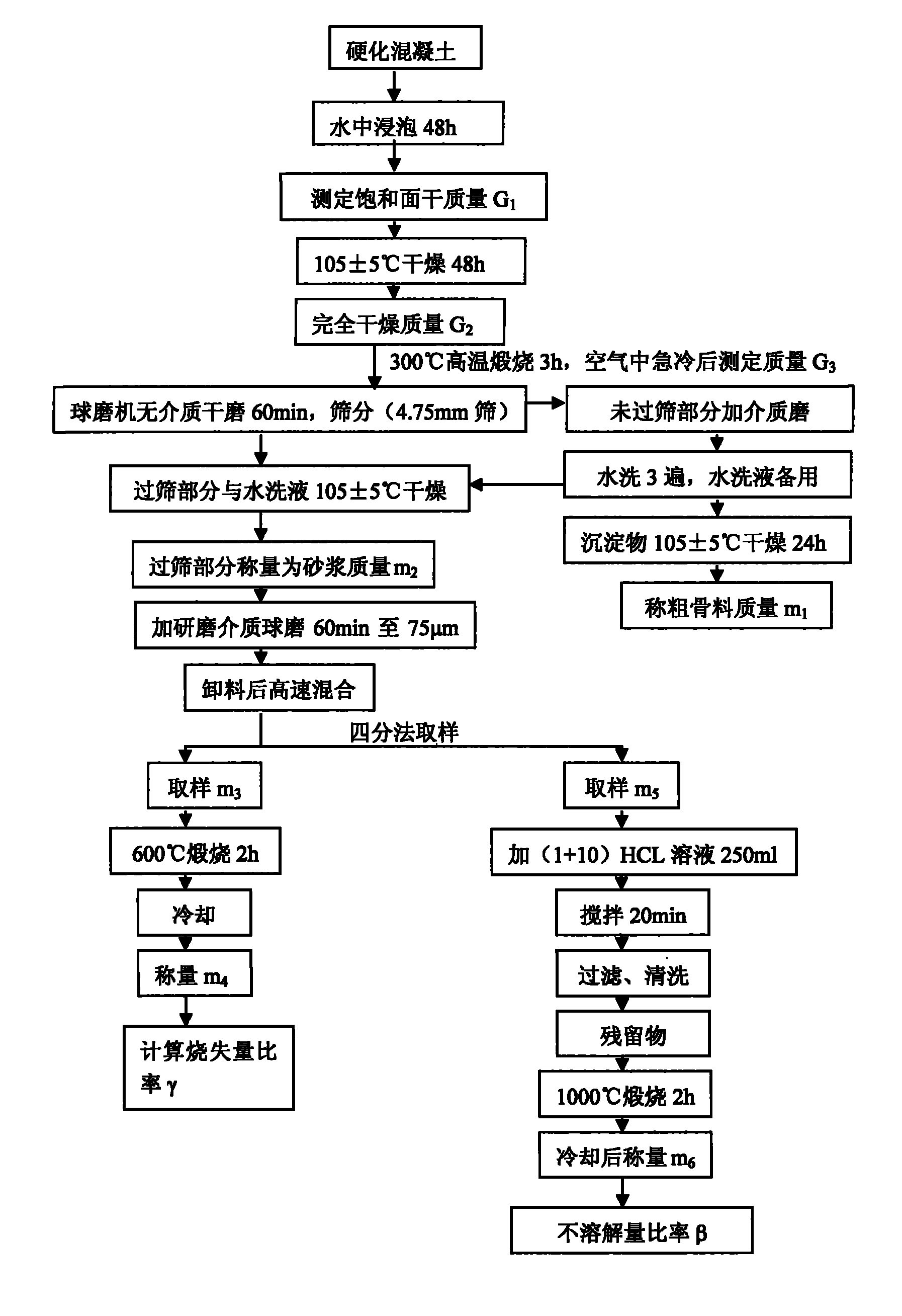

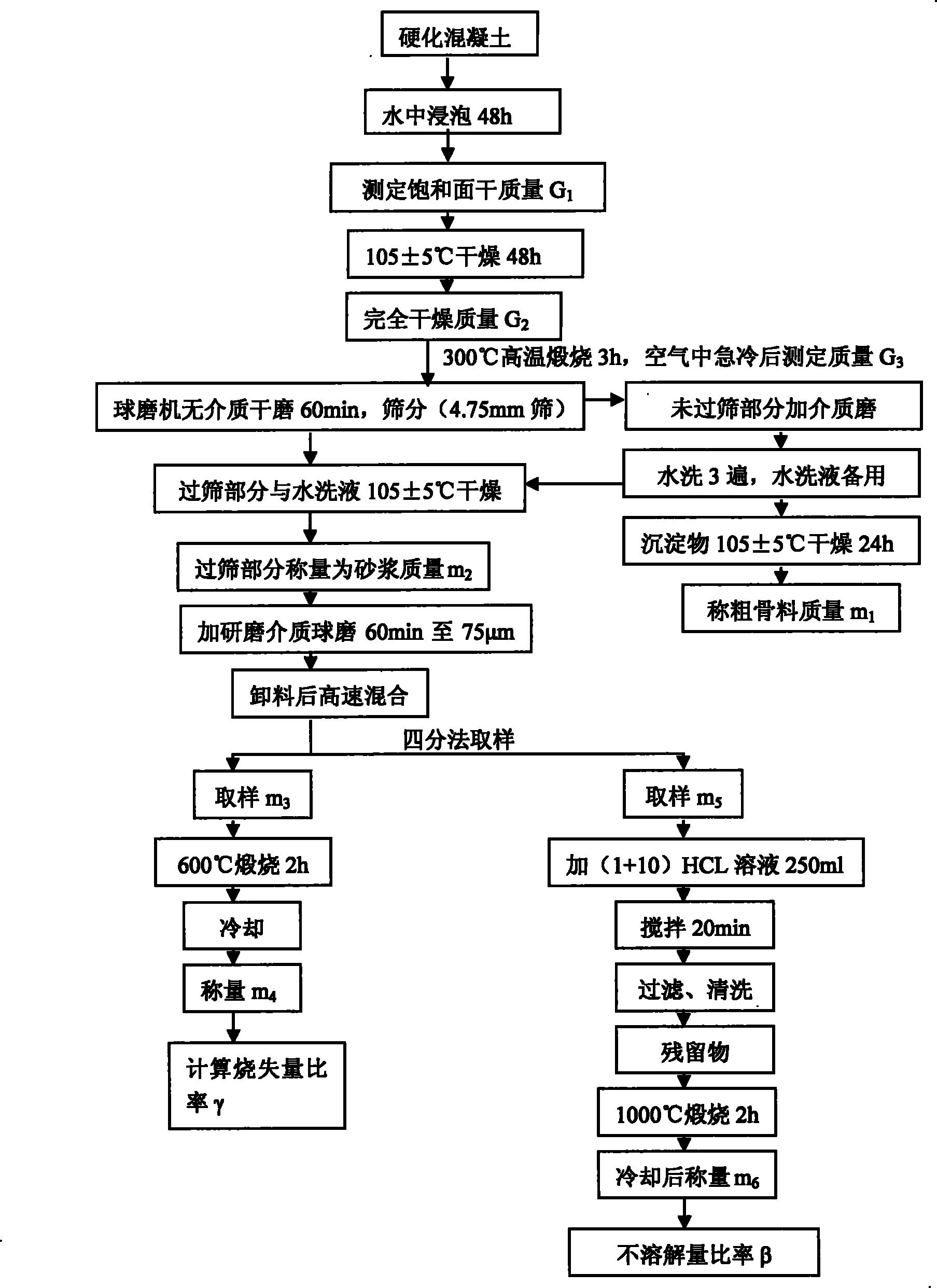

[0048] Embodiments 1 to 5 of the present invention adopt the following method to estimate the mix ratio of hardened concrete:

[0049] A kind of estimation method of hardened concrete mix ratio, described estimation method step is as follows:

[0050] 1. Put the hardened concrete to be tested into water and soak for 48 hours, take out the hardened concrete and wipe the surface dry to form a dry hardened concrete block at the saturated surface, and the measured quality is the dry mass of the saturated surface of the hardened concrete as G 1 ; The dry hardened concrete block on the saturated surface is heated and dried for the first time at 100-110° C. for 48 hours to obtain a concrete block in an absolutely dry state. The measured quality is the mass of the hardened concrete after absolute drying, which is calculated as G 2 The obtained concrete block in an absolutely dry state was heated at 300°C for 3 hours, and the heated concrete block was taken out and rapidly cooled to ro...

Embodiment 1

[0081] Estimation of hardened concrete mix ratio after 56 days of molding

[0082] The cement used in the experiment is PO32.5 cement produced by Qianchao Cement Factory. The maximum particle size of the limestone coarse aggregate used is 40cm. The water is drinking tap water. The sand is medium (river) sand (its fineness modulus is 2.7). Concrete was prepared according to the mix ratio shown in Table 1, and the slump of the obtained concrete mixture was 50-100mm. There were 9 concrete samples in each group, and the size of the specimen was 100mm×100mm×100mm. The concrete specimen was prepared according to the current standard method. And standard curing (the molded specimens are cured naturally for 24 hours, then removed from the formwork, and then cured in water at room temperature for 28 days); the components of each group of concrete designed are:

[0083] A1: cement / stone (coarse aggregate) / sand (fine aggregate) / water=1.00 / 2.60 / 1.46 / 0.45

[0084] A2: cement / stone (coarse...

Embodiment 2

[0100] Estimation of the mix ratio of hardened concrete after 180 days of molding

[0101] The cement, coarse aggregate, sand, water, etc. used in the experiment are the same as the above-mentioned embodiment 1; the size, preparation and curing method of the test piece are all the same as the above-mentioned embodiment 1; the components of each group of concrete designed are the same as the above-mentioned embodiment 1; after 28 days After taking it out and storing it in the indoor environment for 152 days, use 3 of the above-mentioned remaining 6 samples of each group to carry out the mixing ratio estimation test according to the accompanying drawing 1 of the specification, and the remaining 3 samples will continue to be stored indoors for use.

[0102] Table 3 shows the mean values of the measurement results and the calculation process of the three samples in each group after 180 days of molding.

[0103] Table 3 The mean value of the measurement results of each group of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com