A self-insulating lightweight wallboard containing hollow ceramsite and its preparation method

A lightweight wallboard and self-insulating technology, applied in the field of building materials, can solve the problems that wallboards cannot well adapt to multi-functional and high-performance requirements, pollution discharge, energy consumption, etc., and achieve good resistance to tensile deformation, Saving resources, small holes and small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

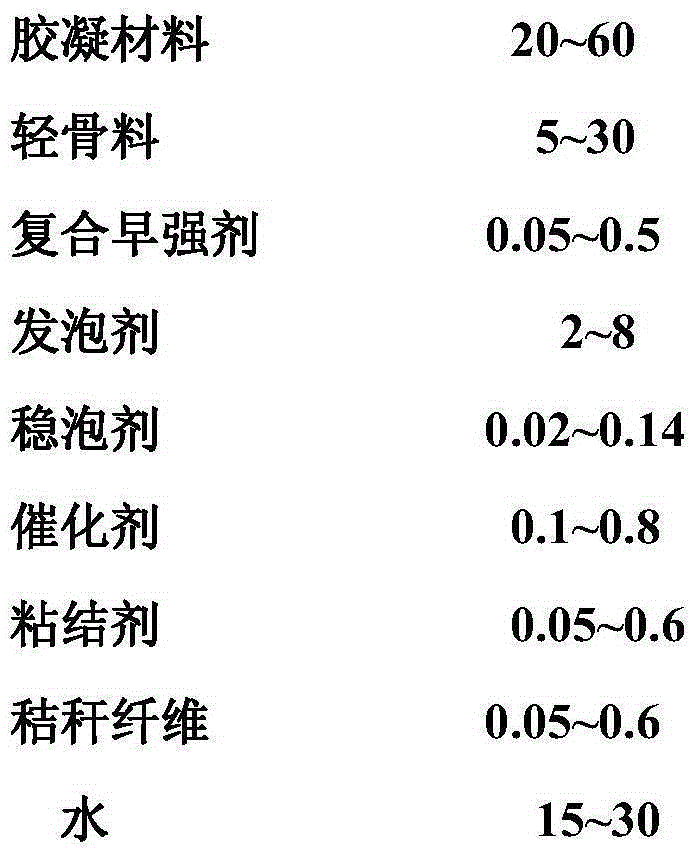

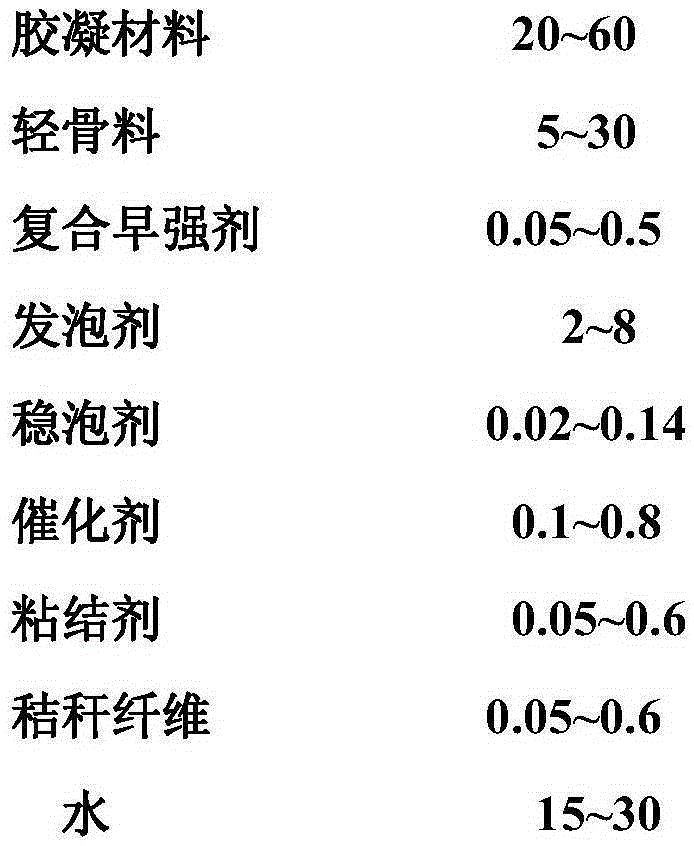

[0026] Take the raw material according to the following parts by weight:

[0027] 42.5MPa ordinary Portland cement 23, slag powder 20, hollow ceramsite 9, closed-cell expanded perlite 8, expanded vermiculite 3, straw fiber 0.3, 30% hydrogen peroxide solution 6, gelatin 0.08, 30% potassium permanganate Aqueous solution 0.42, 200000Pa.S hydroxypropyl methylcellulose 0.2, water 30.

[0028] After the raw materials are prepared, the preparation method is as follows:

[0029] (1) Mix the cement and fly ash or cement and slag powder, straw fiber, composite early strength agent and binder together for 2 to 4 minutes, and then mix according to the ingredients. The required water, foaming agent, stabilizer, and catalyst are added in sequence, and the stirring is continued for 4 to 8 minutes to obtain a slurry mixture;

[0030] (2) Add hollow ceramsite, closed-cell perlite and expanded vermiculite in saturated surface dry state to the slurry mixture obtained in step (1), stir for 2 to...

Embodiment 2

[0032] Take the raw material according to the following parts by weight:

[0033] 42.5MPa ordinary Portland cement 21, slag powder 25, hollow ceramsite 10, closed-cell expanded perlite 6.5, expanded vermiculite 3.5, straw fiber 0.35, 30% hydrogen peroxide solution 4.1, gelatin 0.05, 30% potassium permanganate Aqueous solution 0.35, 200000Pa.S hydroxypropyl methylcellulose 0.15, water 31.

[0034] After the raw materials are prepared, the preparation method is as follows:

[0035] (1) Mix the cement and fly ash or cement and slag powder, straw fiber, composite early strength agent and binder together for 2 to 4 minutes, and then mix according to the ingredients. The required water, foaming agent, stabilizer, and catalyst are added in sequence, and the stirring is continued for 4 to 8 minutes to obtain a slurry mixture;

[0036] (2) Add hollow ceramsite, closed-cell perlite and expanded vermiculite in saturated surface dry state to the slurry mixture obtained in step (1), stir...

Embodiment 3

[0038] Take the raw material according to the following parts by weight:

[0039] 42.5MPa ordinary Portland cement 20, slag powder 20, hollow ceramsite 11, closed-cell expanded perlite 8, expanded vermiculite 4.5, straw fiber 0.3, 30% hydrogen peroxide solution 3.5, gelatin 0.04, 30% potassium permanganate Aqueous solution 0.3, 200000Pa.S hydroxypropyl methylcellulose 0.36, water 28.

[0040] After the raw materials are prepared, the preparation method is as follows:

[0041] (1) Mix the cement and fly ash or cement and slag powder, straw fiber, composite early strength agent and binder together for 2 to 4 minutes, and then mix according to the ingredients. The required water, foaming agent, stabilizer, and catalyst are added in sequence, and the stirring is continued for 4 to 8 minutes to obtain a slurry mixture;

[0042] (2) Add hollow ceramsite, closed-cell perlite and expanded vermiculite in saturated surface dry state to the slurry mixture obtained in step (1), stir for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com