Device and method for continuously measuring saturated surface dry state of pre-wetted aggregate

A measuring method and technology of measuring device, which are applied in measuring device, drying gas arrangement, drying, etc., can solve the problem of adding load cell, unable to remove moisture of aggregate pile, lack of effective measuring method for the dry state of saturated surface of aggregate, etc. problem, to achieve the effect of simple operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

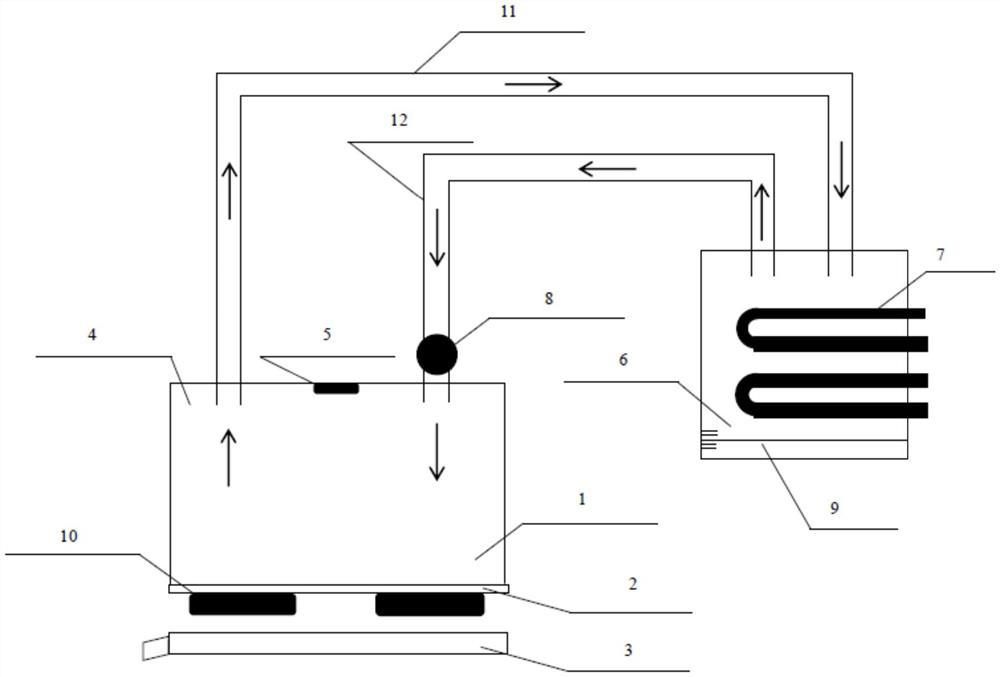

[0035] Please refer to figure 1 , a method for continuously measuring the dry state of the saturated surface of pre-wet aggregate, comprising the steps of:

[0036] Step S1, measure the standard water absorption rate w of the dry aggregate under the saturated surface dry state;

[0037] Step S2, before the dry aggregate is pre-wetted, weigh the mass of the dry aggregate in the hopper as m g :

[0038] Step S3, according to the formula m=m g ·w, calculate the moisture content m of the batch of aggregate surface in dry and saturated state;

[0039] Step S4, after the aggregate is pre-wetted, weigh the mass of the pre-wetted aggregate 1 in the hopper as m s ;

[0040] Step S5, the pre-wet aggregate 1 is loaded on the perforated plate 2, and transported into the drying chamber 4 by the conveying device for drying treatment. A water collection tank 3 is installed under the perforated plate 2, and a temperature and humidity sensor 5 is installed in the drying chamber 4;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com