Method for comprehensively measuring saturated surface dry water absorption of artificial sand

A technology of water absorption and artificial sand, applied in soil material testing, measuring devices, instruments, etc., can solve problems such as inaccurate detection, and achieve the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1, a method for comprehensively measuring the dry water absorption rate of artificial sand saturation surface, used to detect tuff artificial sand in Yongtai pumped storage power station, the measuring steps are:

[0032] 1. The tuff artificial sand of Yongtai Pumped-storage Power Station has a fineness modulus of 2.79; take 20kg of dried artificial sand samples, use a 0.08mm sieve to sieve the artificial sand samples into upper and lower parts, and record the upper and lower parts Fraction of the total sample: the content of particles greater than or equal to 0.08mm in the sample is 88.3%; the content of particles smaller than 0.08mm is 11.7%;

[0033] 1.2. The saturated surface dry water absorption rate of the particles on the 0.08mm sieve is measured by "2.2 Apparent Density and Water Absorption Test of Sand Material" in SL352-2006 "Hydraulic Concrete Test Regulations", and the saturated surface dry water absorption rate is 0.83%;

[0034] 1.3. The weight of ...

Embodiment 2

[0052] Example 2. The 11th detection of continuous engineering, limestone artificial sand of Guanling Hydropower Station in Guizhou, fineness modulus 2.97; take 10kg of dried artificial sand samples, and use a 0.08mm sieve to sieve the artificial sand samples into upper and lower sieves Two parts, record the fraction of the above-sieve and under-sieve parts in the total sample: the content of particles greater than or equal to 0.08mm in the sample is 88.6%; the content of particles smaller than 0.08mm is 11.4%;

[0053] 2.2. Among them, the saturated surface dry water absorption rate of the particles on the 0.08mm sieve is 1.05%;

[0054] 2.3. The weight of the part under the sieve is 1140g. Due to the continuity of the project, except for the first detection according to the step 1.3 of the above example, the average value of the saturated surface dry moisture content of the previous detection or several detections can be used as a preliminary detection. Estimated, the averag...

Embodiment 3

[0062] Embodiment 3. Zhouning pumped storage power station granite artificial sand, fineness modulus 2.70; Get the artificial sand sample of 20kg drying, use 0.08mm sieve to sieve the artificial sand sample into two parts, the upper part and the lower part of the sieve, and record the upper and lower parts of the sieve. The fraction of the under-sieve part in the total sample: the content of particles greater than or equal to 0.08mm in the sample is 91.7%; the content of particles smaller than 0.08mm is 8.3%;

[0063] 3.2. Among them, the saturated surface dry water absorption rate of the particles on the 0.08mm sieve is 0.88%;

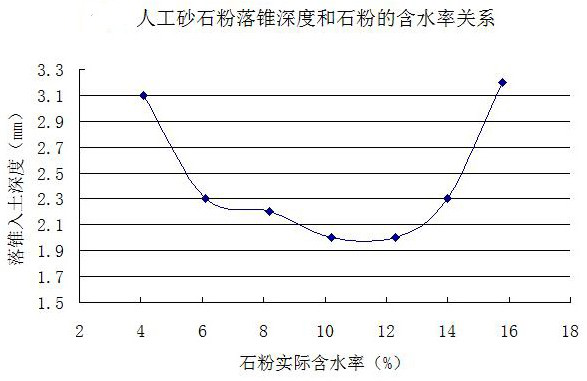

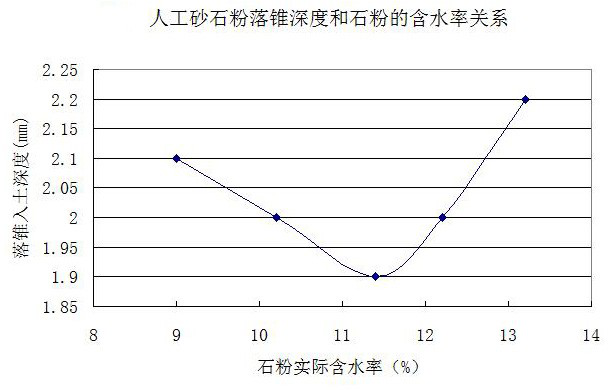

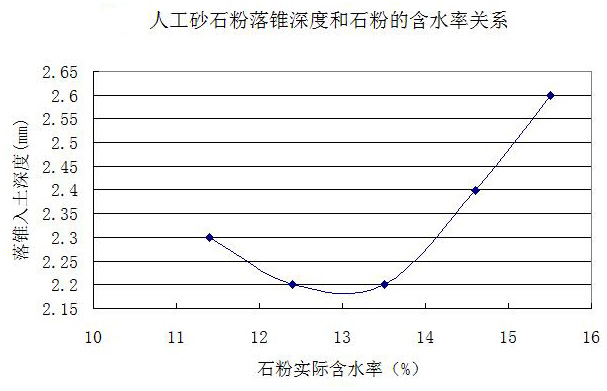

[0064] 3.3. The weight of the part under the sieve is 1660g, and the dry moisture content of the saturated surface of the stone powder detected last time is 9.0%. In order to get higher accuracy, take 9.0% as the middle value, each 150g, a total of 5 pieces, make a stone powder sub-sample every 1%, according to 7%, 8%, 9%, 10%, 11%, add Distilled wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com