A Grading and Evaluation System for Low-Quality Recycled Aggregate

A technology of recycled aggregates and recycled fine aggregates, which is applied in the field of building materials recycling and construction waste recycling, and can solve the problems of no low-quality recycled coarse aggregates and low-quality recycled fine aggregates grading and evaluation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The grading evaluation system for low-quality recycled aggregates described in this example includes the following steps:

[0037] (1) Classification and evaluation of low-quality recycled aggregates:

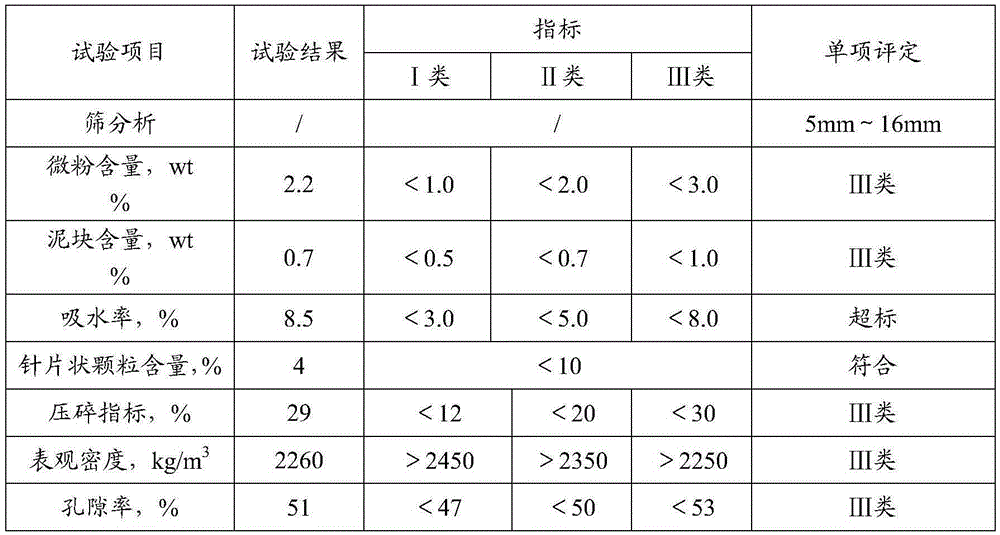

[0038] The low-quality brick recycled coarse aggregate was selected, and the performance was measured according to the method stipulated in the standard GB / T25177-2010 "Recycled Coarse Aggregate for Concrete". The results are shown in Table 1.

[0039] Table 1 Physical performance indicators of low-quality brick recycled coarse aggregate

[0040]

[0041] The low-quality recycled coarse aggregate processed from waste bricks has poor quality except that the water absorption rate does not meet the minimum performance level of recycled coarse aggregate, and other indicators meet the technical requirements of Class III recycled coarse aggregate for concrete.

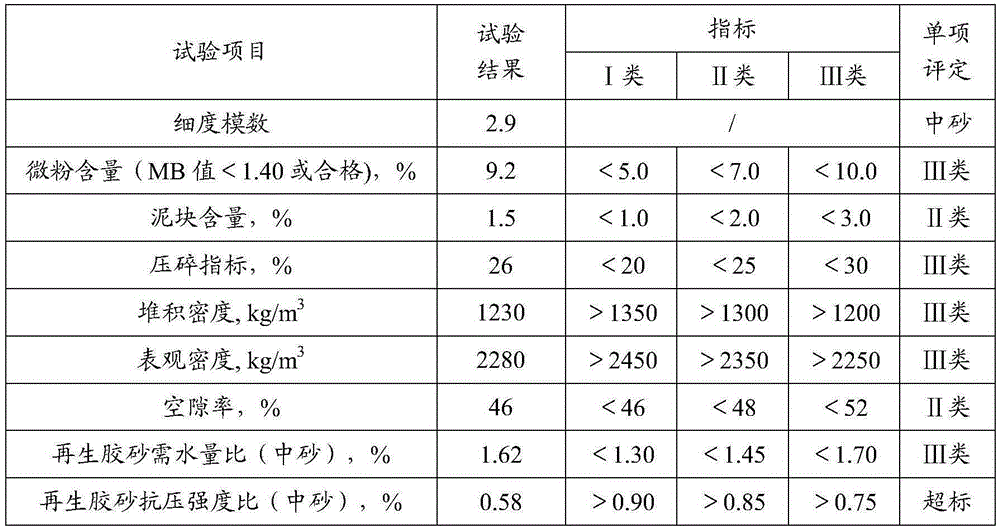

[0042] Select low-quality recycled fine aggregates for bricks, and perform performance measurements according to...

Embodiment 2

[0077] The grading and evaluation system for low-quality recycled aggregates described in this example includes the following steps:

[0078] (1) Classification and evaluation of low-quality recycled aggregates:

[0079] Select low-quality cement stone recycled coarse aggregate, and perform performance measurement according to the method specified in the standard GB / T25177-2010 "Recycled Coarse Aggregate for Concrete". The results are shown in Table 11.

[0080] Table 11 Physical performance indicators of low-quality cement stone coarse aggregate

[0081]

[0082] Recycled coarse aggregate processed from cement stone meets the technical requirements of recycled coarse aggregate for Class I concrete except that the fine powder content meets the performance level of Class III, and the quality is relatively good.

[0083] The low-quality cement stone recycled fine aggregate was selected, and the performance was measured according to the method specified in the standard GB / T25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com