A high-efficiency aggregate saturated surface dry mixing device

A mixing device and aggregate technology, which is applied in the direction of cement mixing device, liquid ingredient supply device, control device, etc., can solve the problems of uneven mixing and blowing, affecting the evaporation effect of aggregate surface water, increasing the working intensity of staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description is only a preferred embodiment of the present invention, and the protection scope is not limited to this embodiment. All technical solutions that belong to the idea of the present invention should belong to the protection scope of the present invention. At the same time, it should be pointed out that, for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

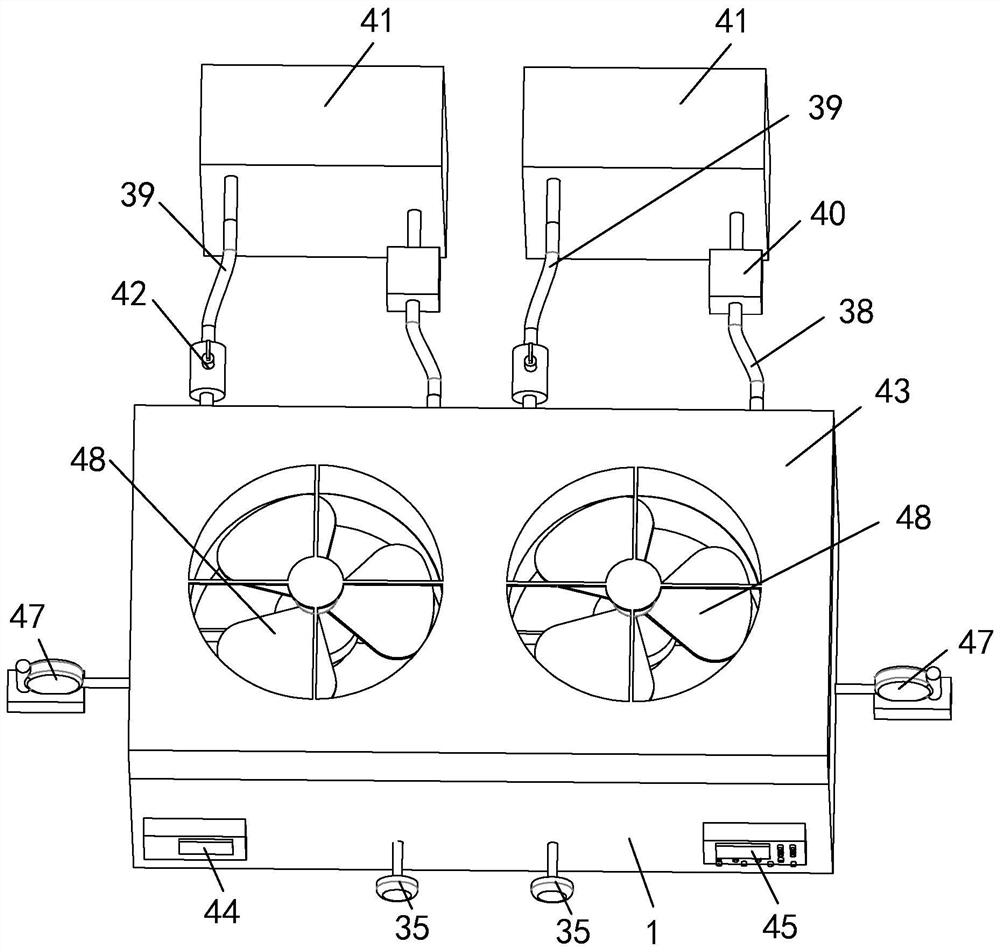

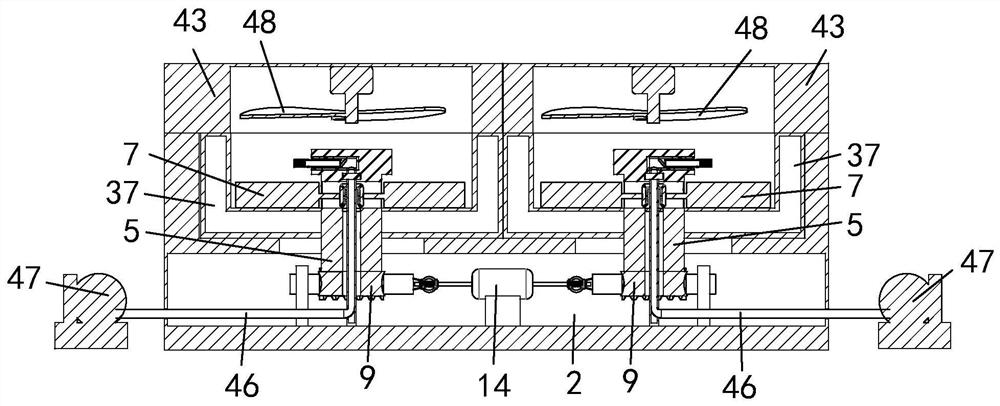

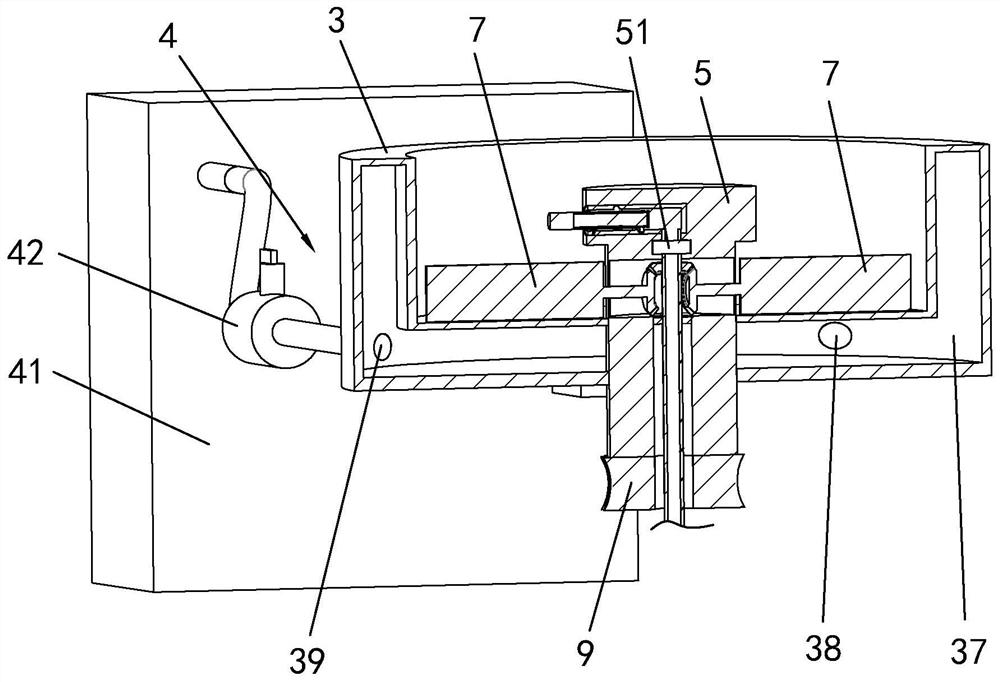

[0034] See Figures 1 to 8 , a high-efficiency aggregate-saturated surface dry stirring device, comprising a box body 1, a cavity 2 arranged in the box body 1 and a mixing drum 3 symmetrically arranged in the box body 1, and the upper end surface of the box body 1 is rotated and provided with protection There are two sets of protective covers 43 , and the two sets of protective covers 43 are located above the mixing drum 3 .

[0035] When the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com