Lime-fly ash macadam waste recycling method

A technology for ash and crushed stone and waste, which is applied in the field of recycling of ash and crushed stone waste, can solve the problems of single recycling method, underutilized, low recycling utilization rate, etc. Simple and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

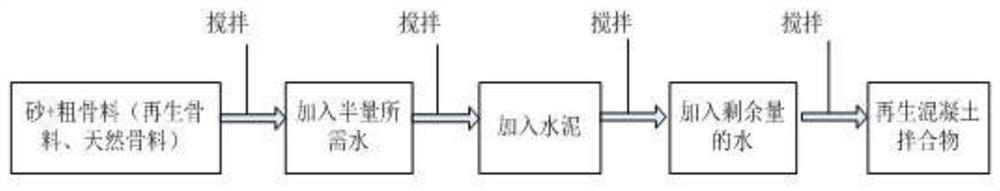

[0030] According to the following process, the regenerated coarse aggregate of fly ash and crushed stone waste is produced:

[0031] (1) Collect the fly ash and gravel waste generated in the project and transport them to the crushing and processing site in a centralized manner;

[0032] (2) Use the crawler chassis to move the impact crushing equipment to carry out head crushing on the imported fly ash gravel waste materials, and the materials after head crushing are screened through the screen to sort different particle sizes, and at the same time screen out the steel bars that may be contained and other pollutants;

[0033] (3) Perform secondary crushing on the materials that do not pass through the set maximum size screen during the head crushing process, until all the fly ash and gravel wastes meet the particle size requirements;

[0034] (4) Mix fly ash crushed stone wastes with different particle sizes according to a certain ratio to obtain regenerated coarse aggregate o...

Embodiment 2

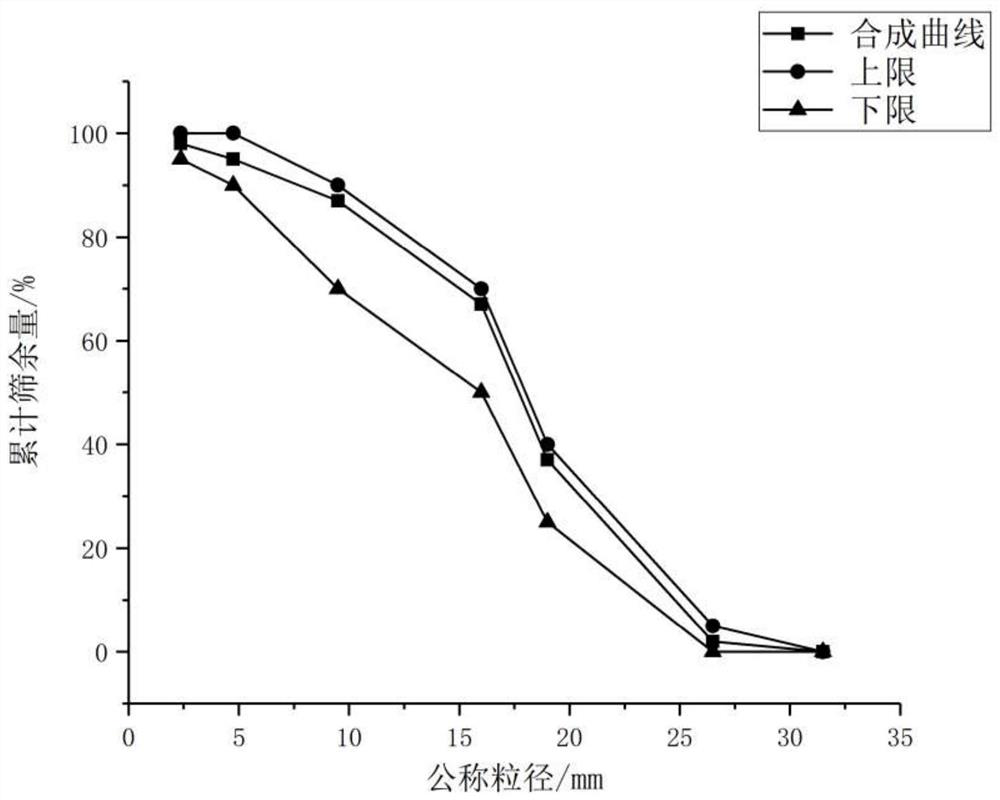

[0046] According to the process of embodiment 1, the regenerated coarse aggregate of waste limestone gravel is produced, and the recycled coarse aggregate of waste limestone gravel of required particle gradation is obtained, and its specific particle gradation is shown in the following table:

[0047] Table 2 Grading of recycled coarse aggregate from fly ash gravel waste

[0048] Square hole sieve size(mm) 2.36 4.75 9.5 16 19 26.5 31.5 Cumulative sieve residue (by mass) (%) 100 100 90 70 40 5 100

[0049] Mix the raw materials according to the following steps:

[0050] (1) Sieve the natural aggregate, and prepare it into the same gradation as the regenerated coarse aggregate of fly ash crushed stone waste;

[0051] (2) after immersing the regenerated coarse aggregate of fly ash gravel waste in water for 24 hours, air-dry the free water on the surface to obtain saturated surface-dried fly ash gravel waste;

[0052] (3) Weigh 5.1 parts of the a...

Embodiment 3

[0058] According to the process of embodiment 1, the regenerated coarse aggregate of waste limestone gravel is produced, and the recycled coarse aggregate of waste limestone gravel of required particle gradation is obtained, and its specific particle gradation is shown in the following table:

[0059] Table 3 Grading of recycled coarse aggregate from fly ash gravel waste

[0060] Square hole sieve size(mm) 2.36 4.75 9.5 16 19 26.5 31.5 Cumulative sieve residue (by mass) (%) 95 90 70 50 25 0 0

[0061] Mix the raw materials according to the following steps:

[0062] (1) Sieve the natural aggregate, and prepare it into the same gradation as the regenerated coarse aggregate of fly ash crushed stone waste;

[0063] (2) after immersing the regenerated coarse aggregate of fly ash gravel waste in water for 24 hours, air-dry the free water on the surface to obtain saturated surface-dried fly ash gravel waste;

[0064] (3) Weigh 7.8 parts of the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com