Concrete processing method and device for engineering construction

A technology for engineering construction and processing equipment, which is applied in the direction of clay preparation equipment, cement mixing equipment, chemical instruments and methods, etc., can solve the problems of reduced coarse aggregate content, increased fine aggregate content, and low strength, and achieve the goal of reducing processing Effects of process, increase in contact area, and increase in strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A concrete processing method for engineering construction, which is implemented using the following device, comprising the following steps:

[0036] Step S1, screening mountain sand of 0.3-0.6 mm and mountain sand of 0.8-1.18 mm as fine aggregate, and screening pebbles of 5-9.5 mm as coarse aggregate;

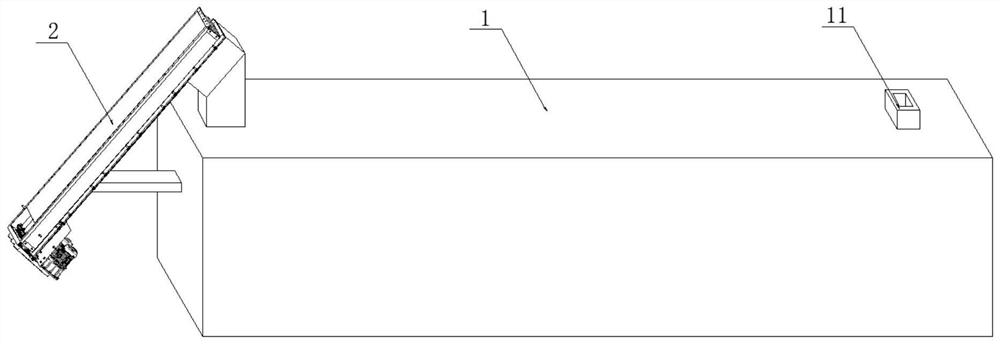

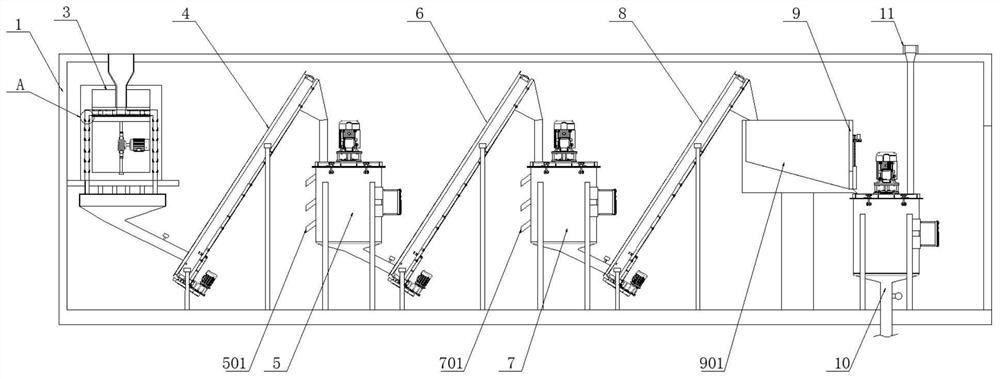

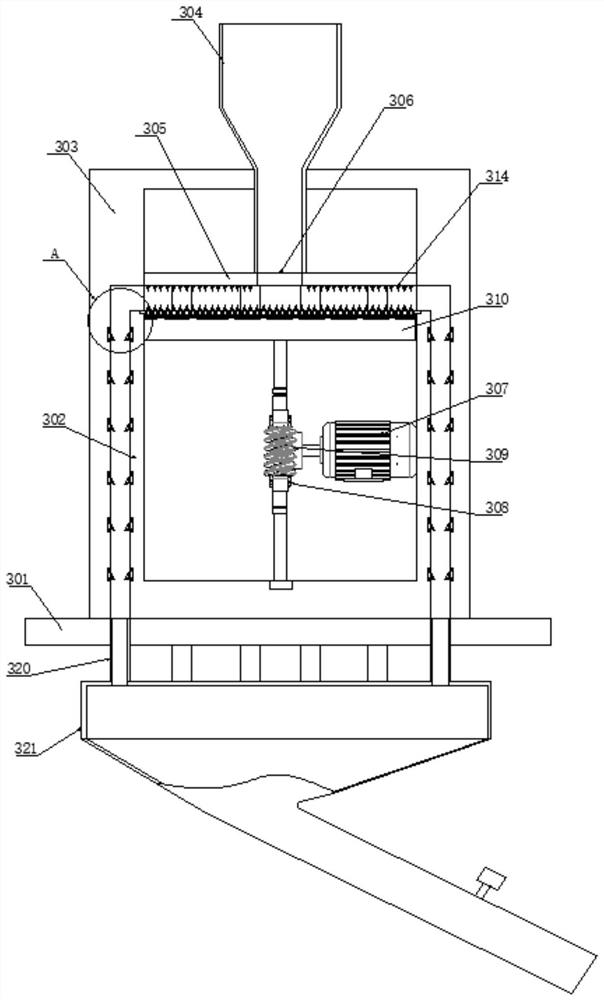

[0037] Such as figure 1 and figure 2 As shown, the device for implementing the method includes a casing 1, a first screw conveying mechanism 2 connected to one end of the casing 1, a grinding mechanism 3 arranged in the casing 1, a second screw conveying mechanism connected to the output end of the grinding mechanism 3 4. The first stirring mechanism 5 connected to the output end of the second screw conveying mechanism 4, the third screw conveying mechanism 6 connected to the output end of the first stirring mechanism 5, the second stirring mechanism 7 connected to the output end of the third screw conveying mechanism 6, The fourth screw conveying mechanism 8 connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com