Efficient aggregate saturated surface dry stirring device

A stirring device and aggregating technology, which can be applied to mixers with rotary stirring devices, transportation and packaging, and accessories of mixers, etc., can solve the problems of difficulty in taking out all the raw materials, the influence of stirring, and the residual raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following descriptions are only preferred implementations of the present invention, and the scope of protection is not limited to this embodiment. All technical solutions under the idea of the present invention shall belong to the scope of protection of the present invention. At the same time, it should be pointed out that for those skilled in the art, some improvements and modifications without departing from the principle of the present invention should also be regarded as the protection scope of the present invention.

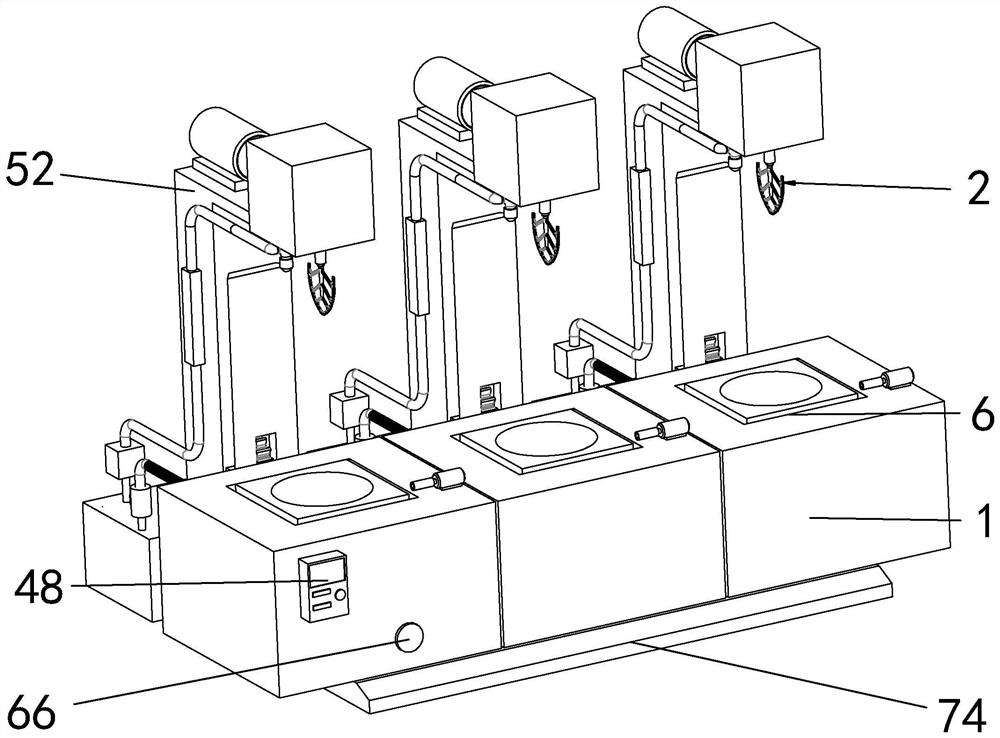

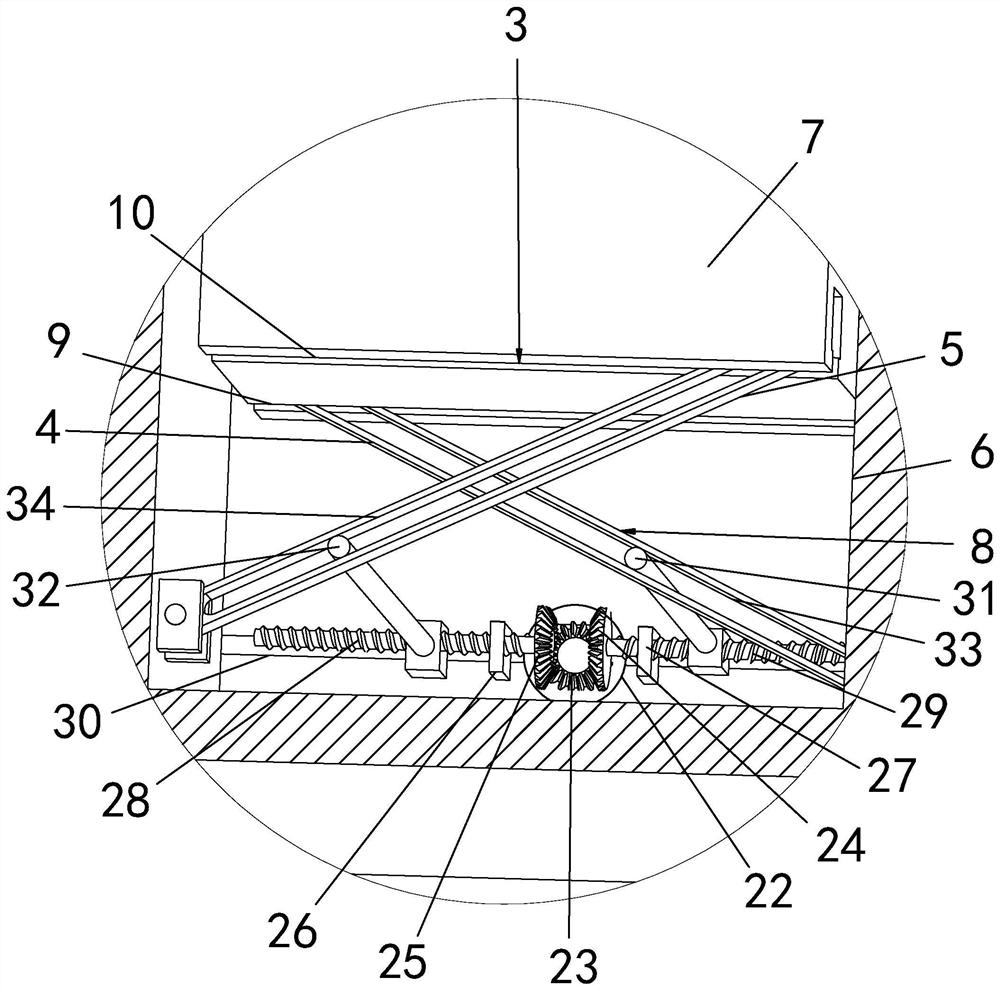

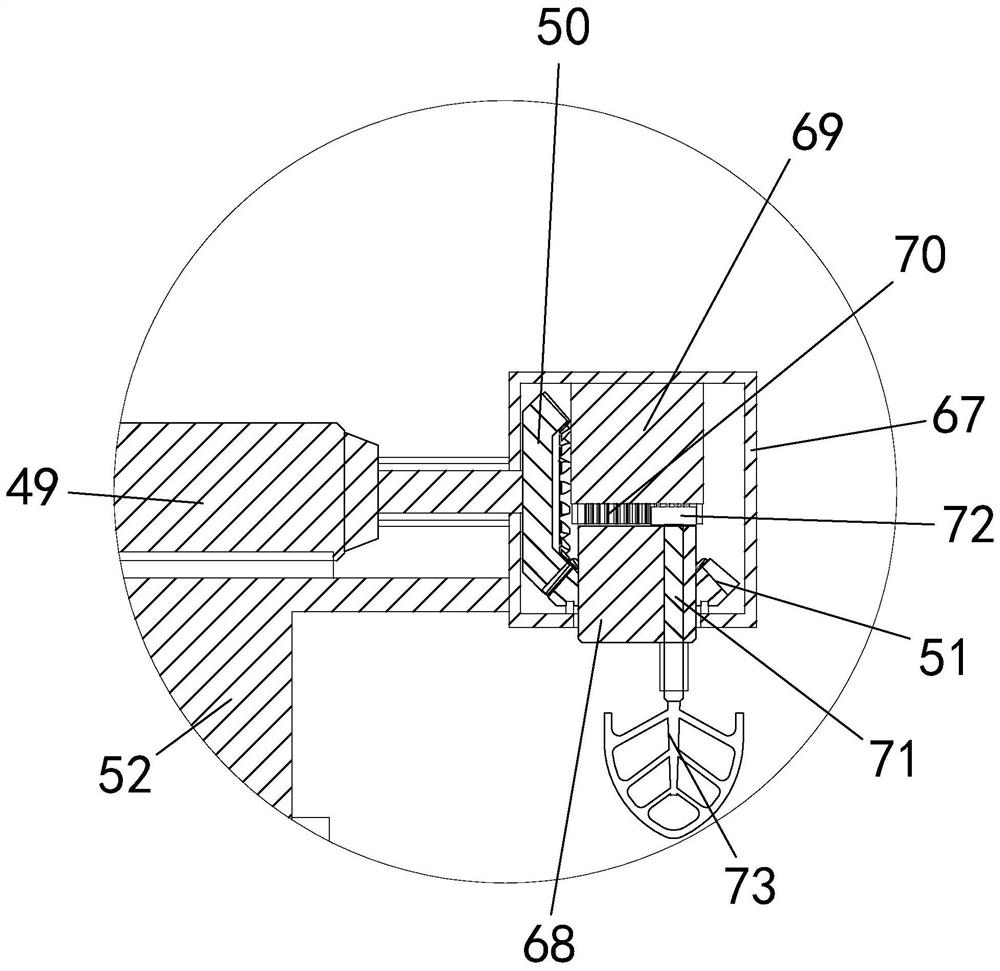

[0040] See Figures 1 to 12 , a high-efficiency aggregate saturated surface dry mixing device, including a bottom plate 74, a number of pillars 52 fixed on the bottom plate 74, a base 1 that is slidably arranged on the pillar 52, and a stirring device 2 that is arranged on the pillar 52, and is also included. The material placement device 3 on the base 1, the heating assembly 59 arranged on one side of the mixing drum 7 and the moving device 75 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com