Method for producing lactone tofu in box and system thereof

A production method and production system technology, applied in the direction of cheese substitutes, dairy products, applications, etc., can solve the problems of large water consumption, high energy consumption, and difficulty in unpacking, so as to reduce water consumption, reduce energy consumption, The effect of reducing the production link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

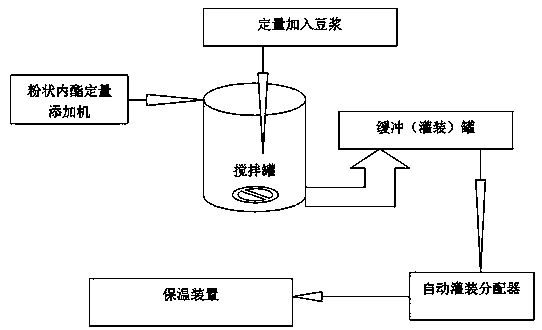

[0028] Take 10L of soybean milk prepared in a known way (by weight: beans: water = 1:8), and heat and boil the milk in a known way. When the boiled soybean milk cools down to 75°C, add powdered gluconic acid- 28g of δ-lactone, stir and mix quickly in a mixer for 10s, then let it stand in the buffer tank for 2.5-4min, after the soybean protein in the soymilk undergoes micro-agglomeration to form condensed particles, then pass through the lower discharge port naturally After pouring into the packaging box for filling, immediately put it into a water tank at 75°C, keep it warm for 20 minutes, solidify into tofu, and cool it to normal temperature with water to obtain the desired lactone box tofu. The results showed that the tofu solidified and formed well, there was no adhesion between the tofu and the inner surface of the packaging box, and the taken out tofu pieces were intact and tender, with no sour taste and good elasticity.

[0029] In this embodiment, the coagulant glucono-...

Embodiment 2

[0032]Take 10L of soybean milk (by weight: beans: water = 1:6), heat and boil the milk, and when the boiled soybean milk cools down to 65°C, add 30g of powdered glucono-δ-lactone, and quickly Electric stirring for 10s, and then stand still in the buffer tank for 3-8 minutes. After the soybean protein in the soy milk is slightly aggregated to form coagulated particles, it will flow naturally into the packaging box through the lower discharge port for filling, and then immediately put it into the 65 ℃ water tank, keep warm for 30 minutes, solidify into tofu, and cool to room temperature with water. The prepared tofu box shows that the tofu has no adhesion to the inner surface of the box wall, the tofu block is complete and tender, has no sour taste and good quality and elasticity.

Embodiment 3

[0034] Take 10L of soybean milk (by weight: beans: water = 1:8) and heat it to boil the milk. When the boiled soybean milk cools down to 85°C, add 28g of powdered glucono-δ-lactone, and quickly electric Stir for 10s, then stand in the buffer tank for 2 to 3 minutes, after the soybean protein in the soy milk is slightly aggregated to form coagulated particles, then flow into the packaging box naturally through the lower discharge port for filling, and immediately put it in 75°C In the water tank, keep warm for 20 minutes, solidify into tofu, and cool the water to normal temperature. The prepared tofu box shows that the tofu has no adhesion to the inner surface of the box wall, the tofu block is complete and tender, has no sour taste and good quality and elasticity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com