a loading and unloading device

A technology of loading and unloading device and driving mechanism, which is applied in the directions of loading/unloading, transportation and packaging, can solve the problems of increasing labor intensity of workers, inconvenient loading and unloading steel pipes, and long loading and unloading time, so as to improve flexibility and applicability and ensure protection effect. , the effect of improving balance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

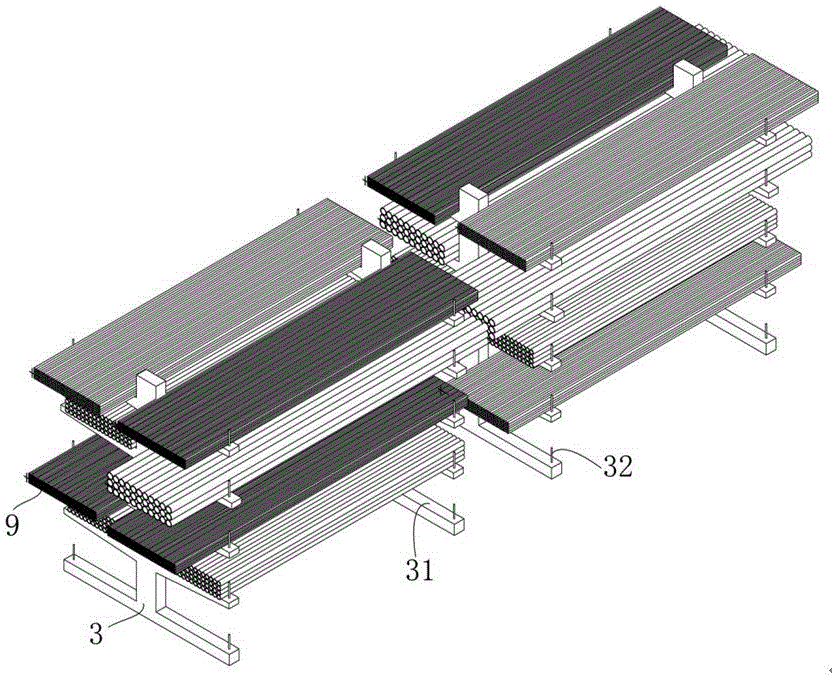

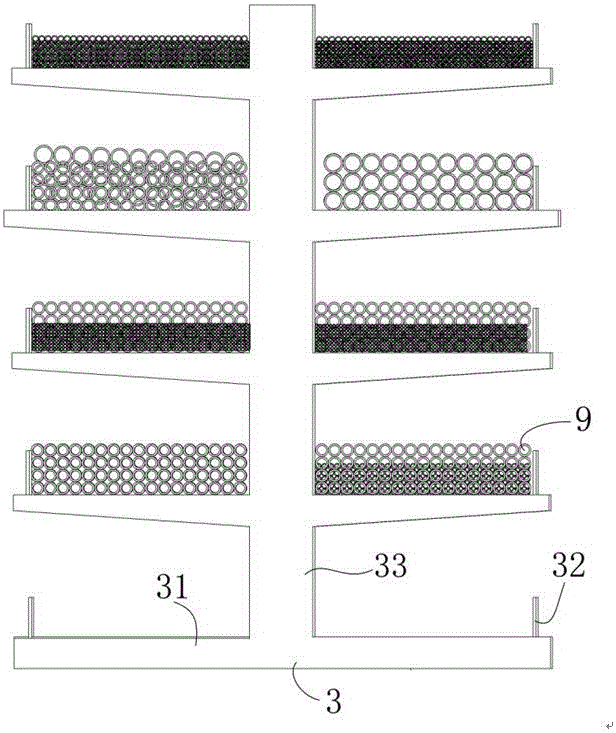

[0029] Embodiment 1 of the loading and unloading device of the present invention includes a drive mechanism and two pick-and-place units arranged side by side in the left and right directions and driven by the drive mechanism to move in the up-down direction and the front-rear direction. In actual use, the pick-and-place unit is often installed on a forklift, and is driven by the forklift to move up and down and forward and backward, that is, the forklift plays the role of a driving mechanism. Of course, the pick-and-place unit can also be installed on a fixed drive. In the mechanism, the driving mechanism drives the pick-and-place unit to take out the pipe or bar and lift it away by the spreader. Since the driving mechanism is not the main improvement of the present invention, and there are many alternative structures, the driving mechanism is no longer shown in the accompanying drawings.

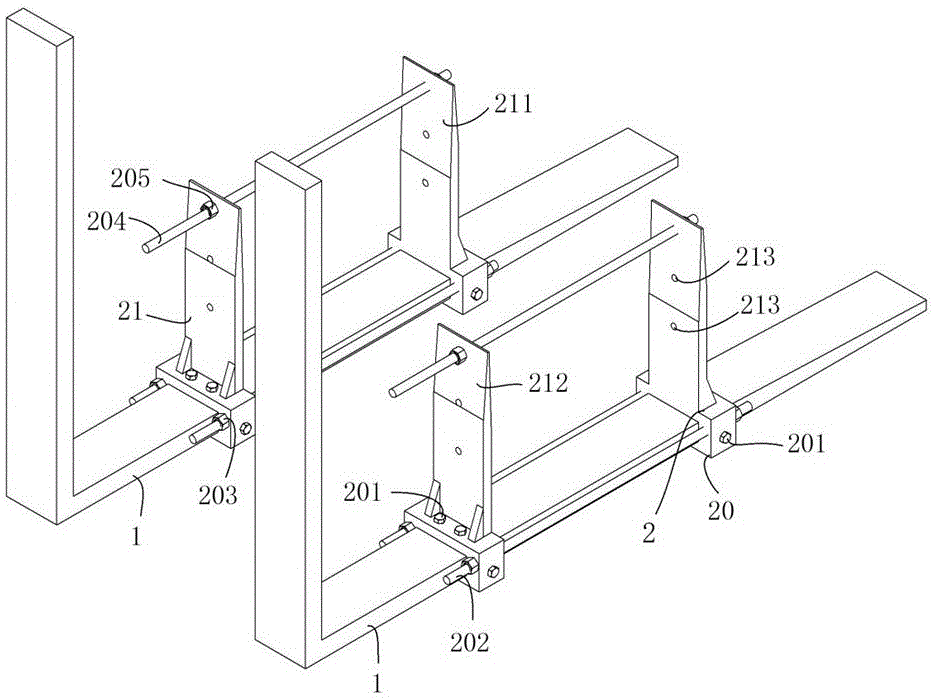

[0030] like Figure 3-5 As shown, the pick-and-place unit includes a main support arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com