A waste tire crushing device for rubber and plastic

A waste tire and crushing device technology, applied in grain processing and other directions, can solve the problems of incomplete tire crushing and low recycling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

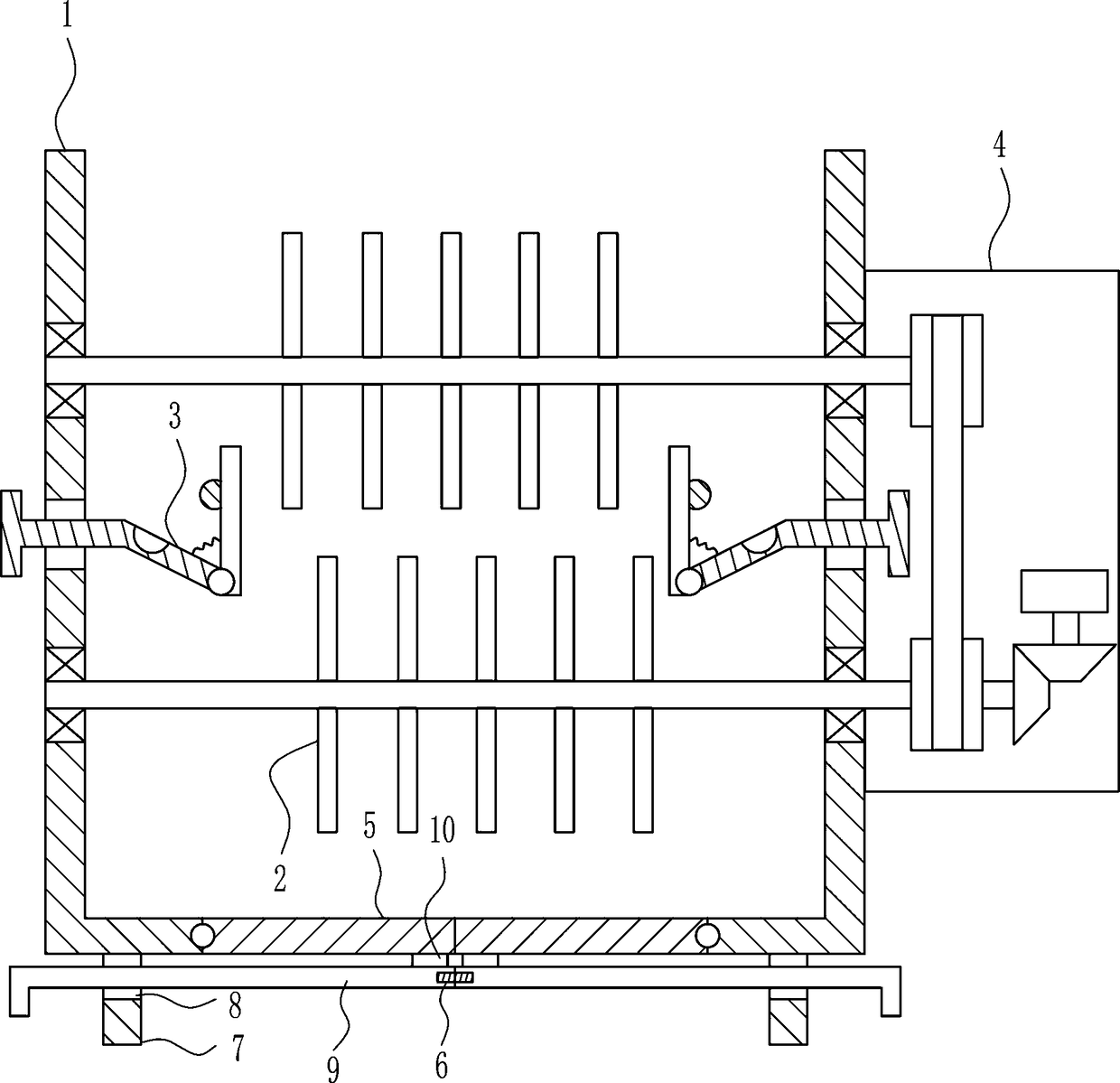

[0036] A waste tire crushing device for rubber and plastics, such as Figure 1-7 As shown, it includes a crushing box 1, a crushing knife 2, a placement mechanism 3 and a driving mechanism 4. The left and right sides of the crushing box 1 are symmetrically provided with a placement mechanism 3, and the crushing box 1 is provided with a driving mechanism 4. The driving mechanism 4 The left part of the blade is evenly connected with a crushing knife 2, and the placing mechanism 3 is located at the front side of the driving mechanism 4.

Embodiment 2

[0038] A waste tire crushing device for rubber and plastics, such as Figure 1-7 As shown, it includes a crushing box 1, a crushing knife 2, a placement mechanism 3 and a driving mechanism 4. The left and right sides of the crushing box 1 are symmetrically provided with a placement mechanism 3, and the crushing box 1 is provided with a driving mechanism 4. The driving mechanism 4 The left part of the blade is evenly connected with a crushing knife 2, and the placing mechanism 3 is located at the front side of the driving mechanism 4.

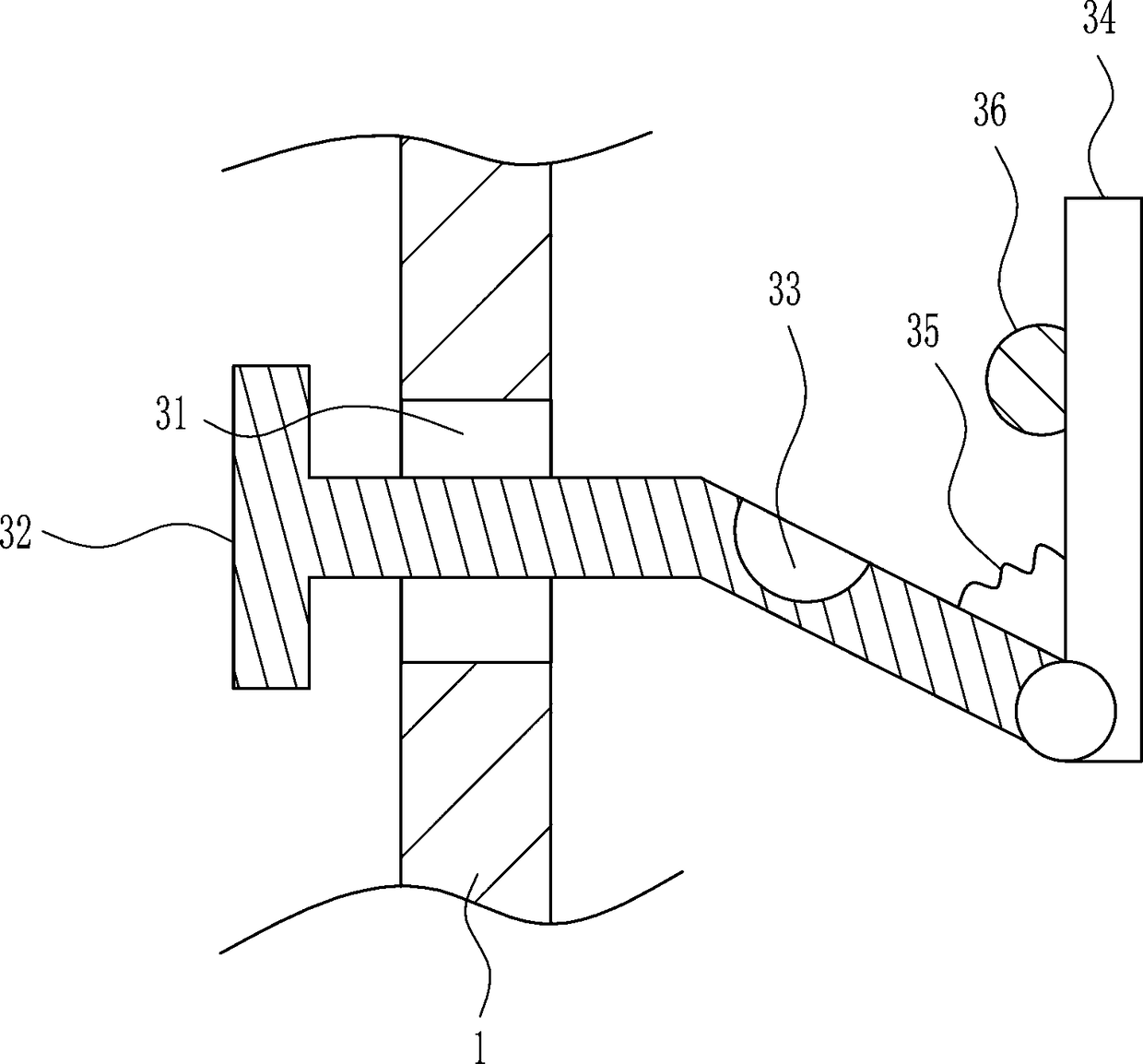

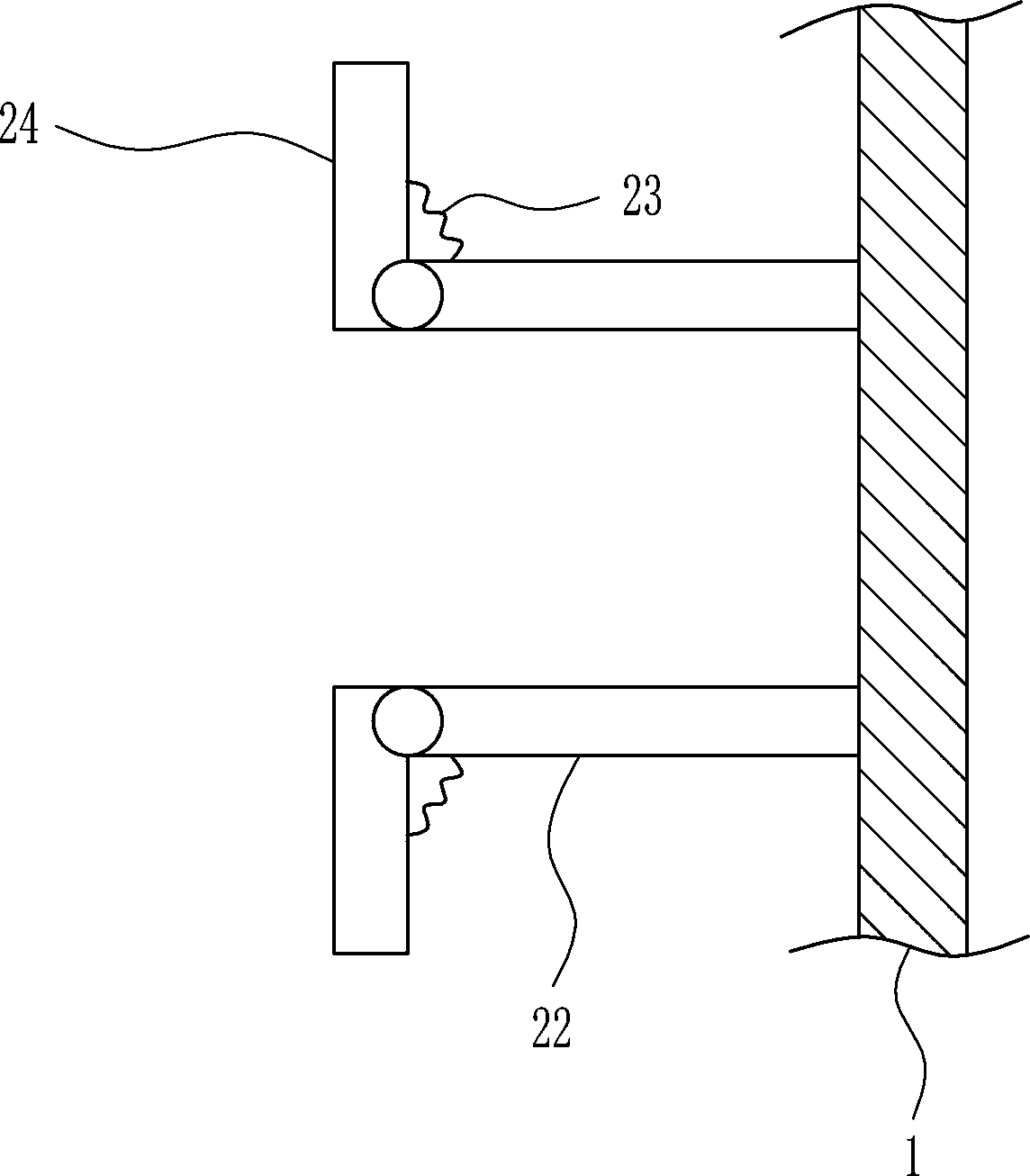

[0039] The placement mechanism 3 includes a first rotating rod 32, a first rotating plate 34, a first spring 35 and a rubber ball 36. The left and right sides of the crushing box 1 are symmetrically provided with a first threaded hole 31 in the middle of the first threaded hole 31. All are provided with the first rotating rod 32, and the outside of the first rotating rod 32 is provided with the external screw thread that cooperates with the firs...

Embodiment 3

[0041] A waste tire crushing device for rubber and plastics, such as Figure 1-7 As shown, it includes a crushing box 1, a crushing knife 2, a placement mechanism 3 and a driving mechanism 4. The left and right sides of the crushing box 1 are symmetrically provided with a placement mechanism 3, and the crushing box 1 is provided with a driving mechanism 4. The driving mechanism 4 The left part of the blade is evenly connected with a crushing knife 2, and the placing mechanism 3 is located at the front side of the driving mechanism 4.

[0042] The placement mechanism 3 includes a first rotating rod 32, a first rotating plate 34, a first spring 35 and a rubber ball 36. The left and right sides of the crushing box 1 are symmetrically provided with a first threaded hole 31 in the middle of the first threaded hole 31. All are provided with the first rotating rod 32, and the outside of the first rotating rod 32 is provided with the external screw thread that cooperates with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com