Prefabricated through hole assembly type reinforced concrete shear wall and construction method of prefabricated through hole assembly type reinforced concrete shear wall

A reinforced concrete and shear wall technology, applied to walls, building components, buildings, etc., can solve problems such as increased workload, disturbance, and high technical level requirements for workers, and achieve the effect of reducing construction difficulty and improving project quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

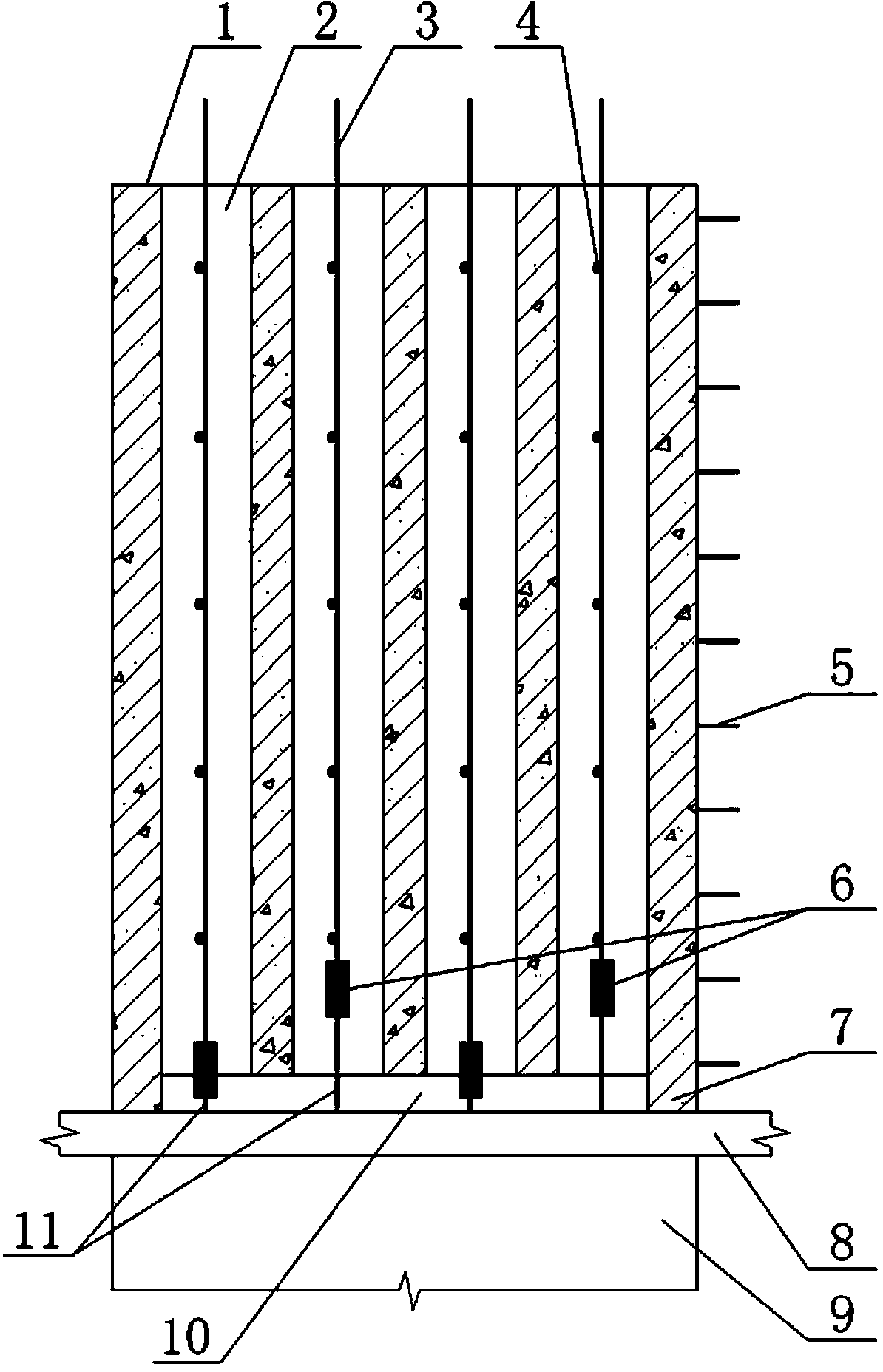

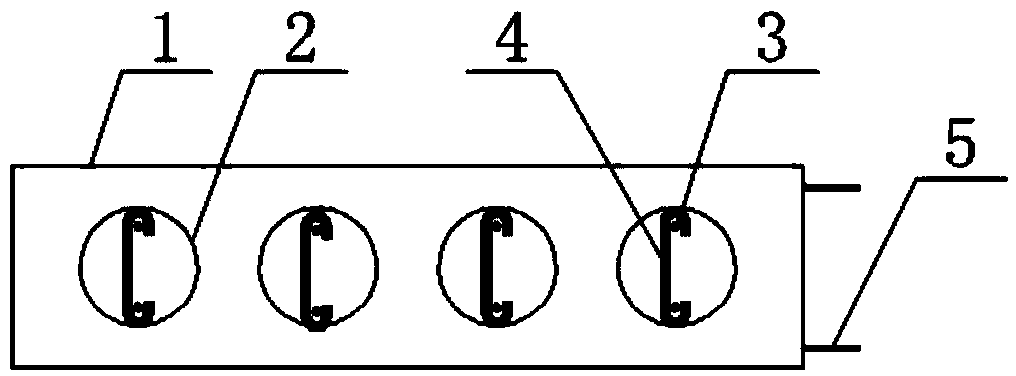

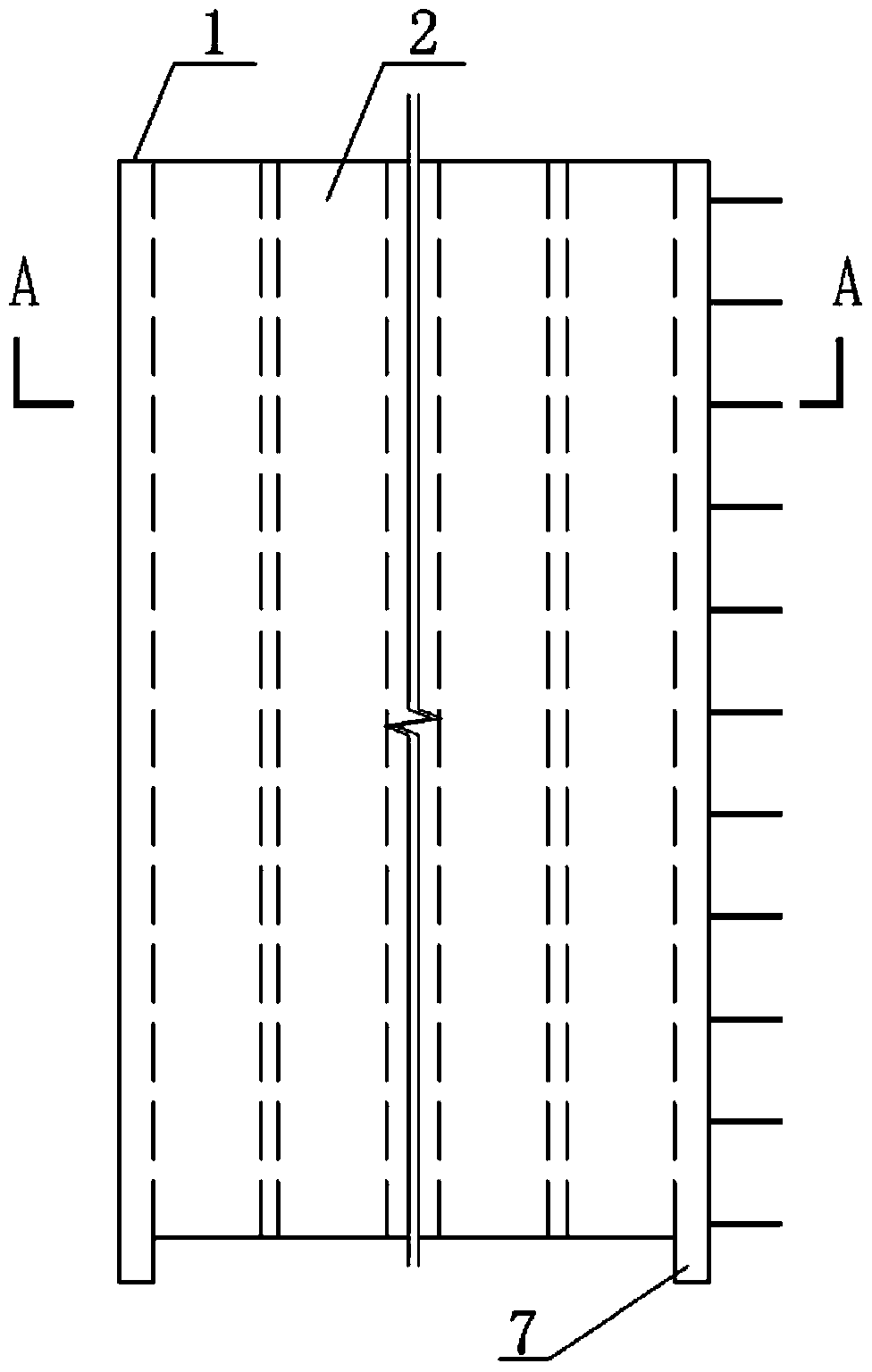

[0029] Prefabricated through-hole fabricated reinforced concrete shear walls with reinforced concrete walls 1 such as Figure 4 As shown, the horizontal steel bar 5 in the wall reinforcement extends to the outside of the wall, and the extended part of the horizontal steel bar is used for the reinforcement of the cast-in-place node between the adjacent shear wall. Straight vias 2, such as Figure 6 As shown, the cross-section of the through hole can be a single shape such as a perfect circle, an ellipse, a rounded rectangle, or a combination of the above-mentioned shapes. Several vertical steel bars 3 that are flexibly connected are respectively housed in each through hole. The vertical reinforcement is fixedly connected by tie reinforcement 4, the upper end of the vertical reinforcement is higher than the wall, the lower end of the vertical reinforcement in the through hole of the upper shear wall is connected with the reinforcement 11 of the lower shear wall, and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com