Steel-fiber concrete combined bridge deck structure with reinforced joints and construction method of steel-fiber concrete combined bridge deck structure

A technology of fiber-reinforced concrete and fiber-reinforced concrete layers, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as reducing the service life of bridge pavement layers, excessive local stress at joints, and reduction of concrete strength, etc., to achieve The effect of reducing the risk of weld fatigue cracking, improving local strength and stiffness, and preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

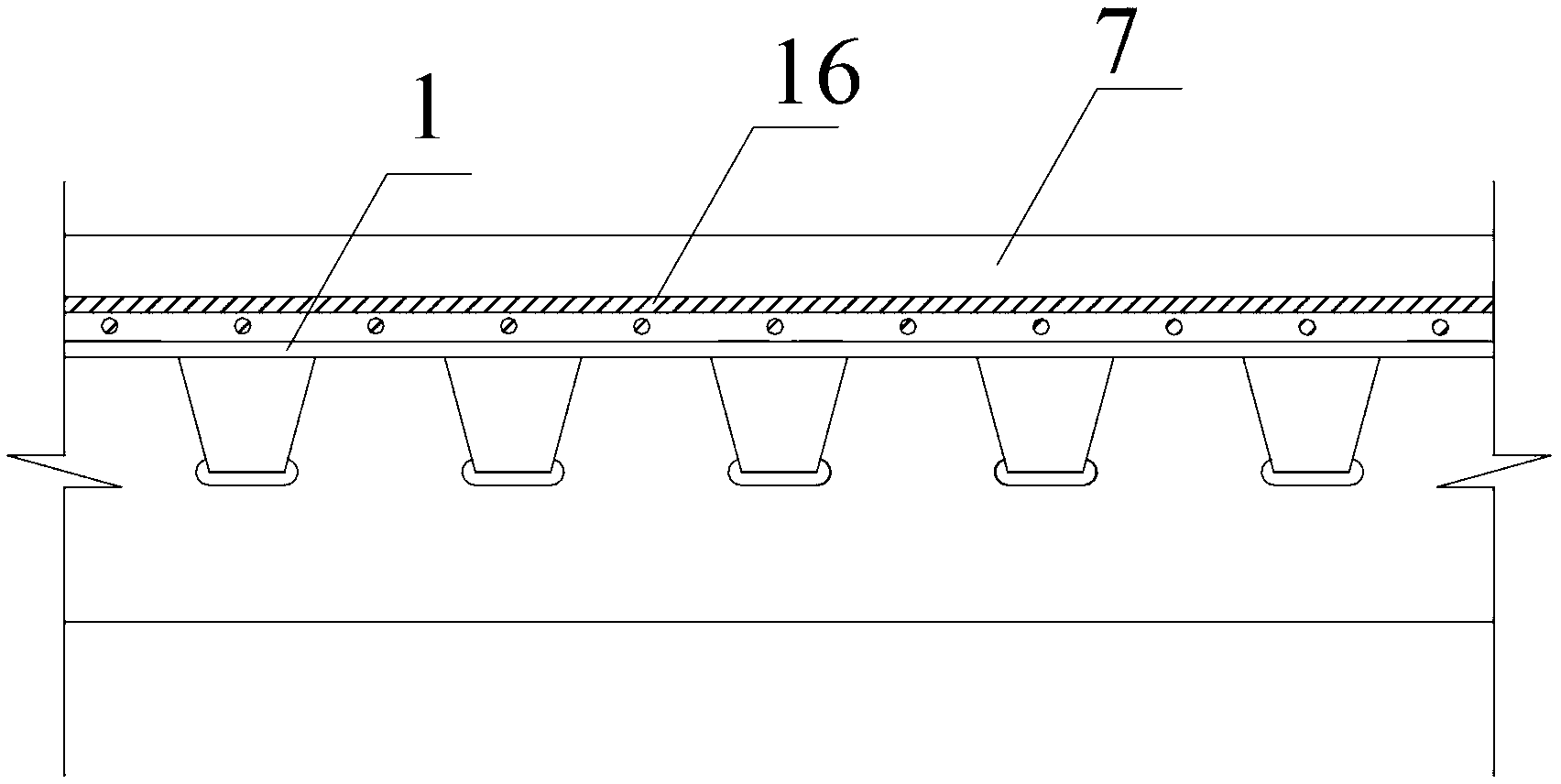

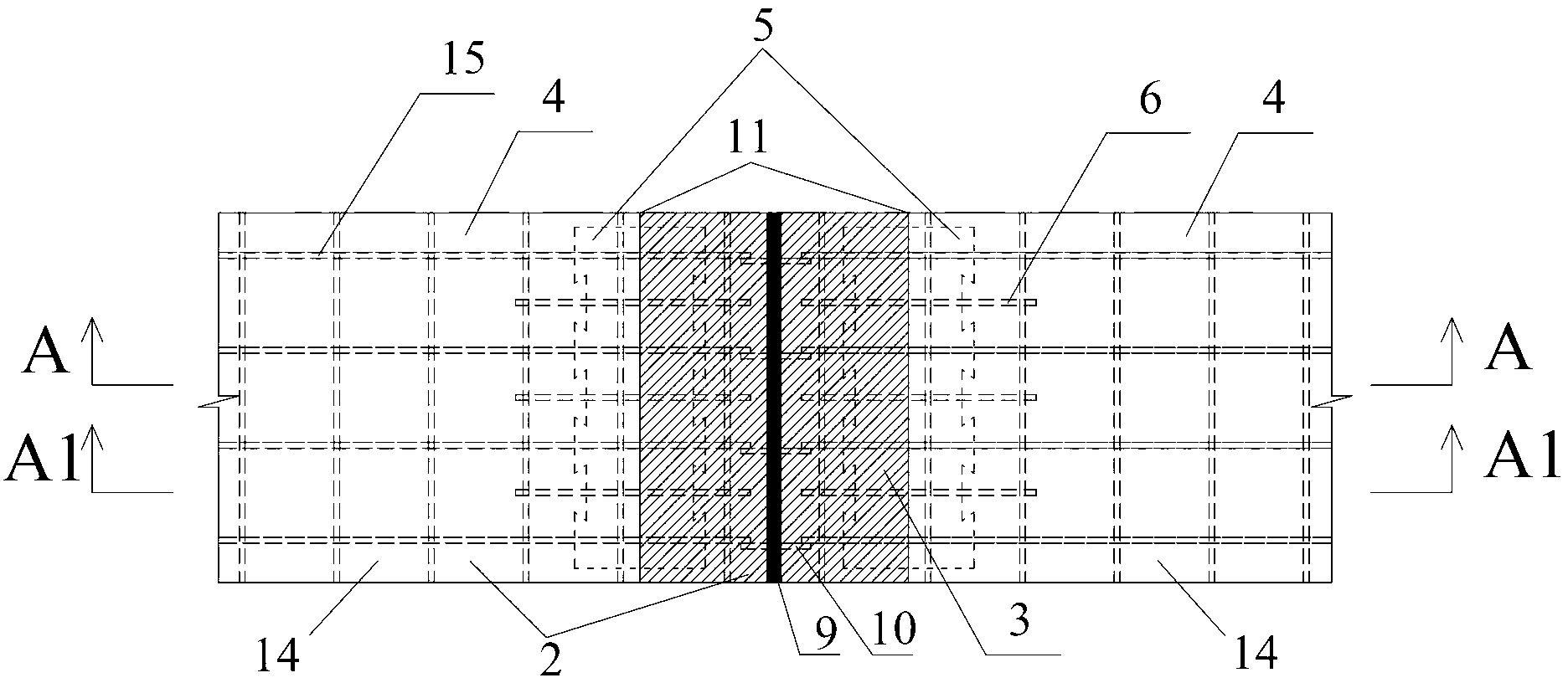

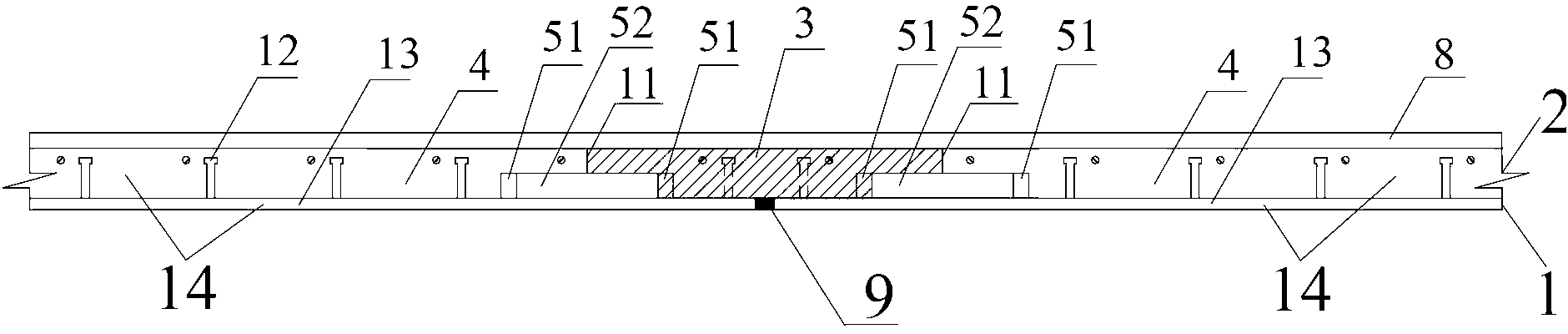

[0043] like Figure 2 ~ Figure 4 As shown, a steel-fiber concrete composite bridge deck structure with reinforced joints of the present invention is mainly composed of multiple steel plate-fiber concrete composite members 14 connected and assembled sequentially along the longitudinal direction of the bridge (in the figure only Two adjacent pieces are shown), the steel plate-fiber concrete composite member 14 includes the steel bridge deck 13 at the lower part and the prefabricated fiber concrete 4 poured on the steel bridge deck 13, the adjacent two steel plate-fiber concrete composite The abutment area of the members 14 is provided with a reinforced joint type construction.

[0044] The reinforced joint structure in this embodiment includes cast-in-place fiber concrete parts 3 and steel plate reinforcement members 5 affixed to the steel bridge deck 13. The steel plate reinforcement members 5 are composed of prefabricated fiber concrete The cast-in-place fiber concrete part...

Embodiment 2

[0054] Such as Figure 6 ~ Figure 8 As shown, a steel-fiber concrete composite bridge deck structure with reinforced joints of the present invention is mainly composed of multiple steel plate-fiber concrete composite members 14 connected and assembled sequentially along the longitudinal direction of the bridge (in the figure only Two adjacent pieces are shown), the steel plate-fiber concrete composite member 14 includes the steel bridge deck 13 at the lower part and the prefabricated fiber concrete 4 poured on the steel bridge deck 13, the adjacent two steel plate-fiber concrete composite The abutment area of the members 14 is provided with a reinforced joint type construction.

[0055] The reinforced joint structure in this embodiment includes cast-in-place fiber concrete parts 3 and steel plate reinforcement members 5 affixed to the steel bridge deck 13. The steel plate reinforcement members 5 are composed of prefabricated fiber concrete The cast-in-place fiber concrete p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com