Whole-high valent titanium slag concrete

A technology for high-titanium heavy slag and high-titanium heavy slag sand, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. problems, to achieve the effect of protecting the environment, reducing the cost of building materials, and improving the quality of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

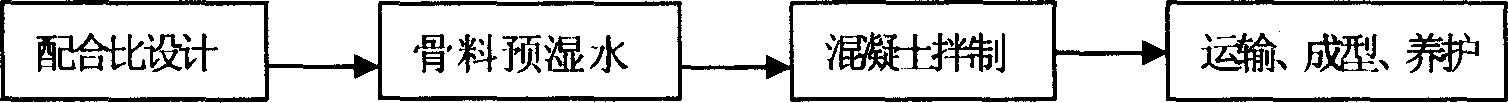

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Take the 5# plain concrete beam and column of Nanshan Garden Zizhuyuan as an example:

[0028] Prepare C35 concrete, the mix ratio is shown in Table 2:

[0029] concrete

Strength etc.

class

Actual consumption of each material (kg / m 3 )

slag sand

high titanite

gravel

Composite Micro

pink

water

C35

327

693

1192

87

230

[0030] 32.5R Huanye cement is used, and the composite micropowder is mixed with 30% blast furnace water slag and 70% phosphorus slag. A mixer was used for on-site mixing, and the high-titanium heavy slag aggregate was wetted 24 hours in advance. The moisture content of the slag sand was 8.2% and the slag crushed stone was 4.2% before the concrete was prepared. Feed in the order of coarse aggregate, cement, admixture, fine aggregate, and water, and the stirring time is 90s. The plug-in vibrator is u...

Embodiment 2

[0033] Example 2: Take commercial concrete mixing plant as an example:

[0034] Commercial concrete mixing plant prepares C50 concrete, and the mix ratio is shown in Table 4:

[0035] concrete

Strength etc.

class

Actual consumption of each material (kg / m 3 )

water

the mud

slag

the sand

High titanium weight

Slag crushed

stone

Composite Micro

pink

water

Tengfengminus

Liquid

C50

450

750

1225

100

190

7.2

[0036] The moisture content of slag sand and slag gravel was measured to be 1.5% before preparing concrete, and the moisture content of slag gravel was 3.2%. The cement is 42.5R ferry cement, and the composite micropowder is mixed with 30% blast furnace water slag and 70% phosphorus slag.

[0037] The measured slump at the construction site is 52mm, and the 28-day compressive strength is 68.8MP...

Embodiment 3

[0038] Example 3: Using high-titanium heavy slag aggregates to prepare road concrete.

[0039] Taking the preparation of M5.0 concrete on Gefu Highway as an example, the mix ratio is shown in Table 5:

[0040] Flexural strength

[0041] 32.5R Huanye cement is used, and the composite micropowder is mixed with 30% blast furnace water slag and 70% phosphorus slag. A forced mixer was used for on-site mixing, and the high-titanium heavy slag aggregate was wetted 24 hours in advance. The moisture content of the slag sand and slag gravel was measured to be 3.0% before concrete preparation. Feed in the order of coarse aggregate, cement, admixture, fine aggregate, and water, and the mixing time is 120s.

[0042] The measured results are shown in Table 6:

[0043]

[0044] Meet the requirements of road concrete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com