Construction method for preventing and treating cracks between concrete structure and filler wall

A concrete structure and filling wall technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problem of wall plastering layer, surface cracking of paint layer, increased risk of external wall leakage, and block wall Poor integrity and other problems, to achieve the effect of eliminating the risk of leakage, considerable social benefits, and reducing construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

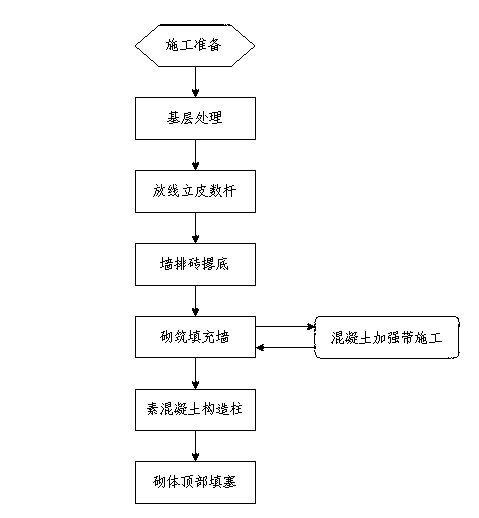

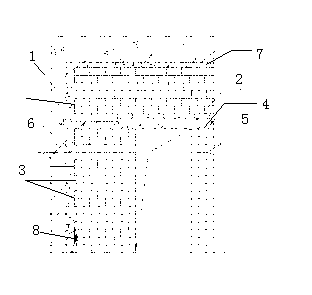

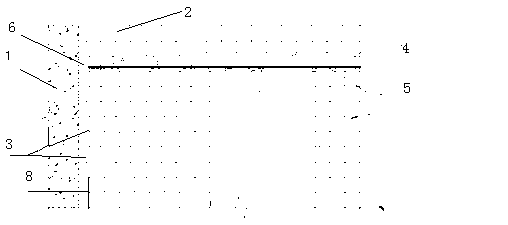

[0041] Please combine figure 1 , figure 2 , image 3 Shown, concrete structure of the present invention and filling wall crack prevention construction method are:

[0042] Step 1: Construction preparation;

[0043] (a) The subdivision of the main concrete structure has been constructed and passed the acceptance.

[0044] (b) Make a number rod, indicating the number of masonry skins, the thickness of mortar joints, the dimensions and elevations of door and window openings, wooden bricks, tie bars, ring beams, etc.;

[0045] (c) The tie bars between the infill wall and the concrete structure walls, columns, and beams are connected by chemical planting bars according to the design specifications and spacing, and the pull-out test of the anchor bars is carried out, which conforms to the "Code for Acceptance of Construction Qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com