High early strength and high corrosion resistant Portland cement and preparation method thereof

A technology of portland cement and calcium silicate, which is applied in the field of cement production and building materials, can solve the problems of cement-based materials such as weak anti-deterioration ability, increased construction difficulty, and reduced early strength, etc., and achieves strong chloride ion curing ability, The effect of shortening the curing time and improving the release strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

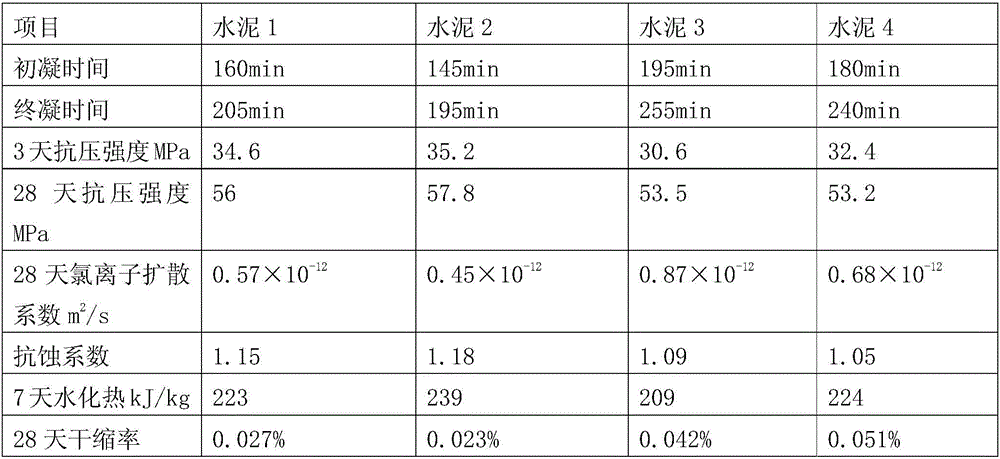

Examples

Embodiment 1

[0030] A high-early-strength, high-corrosion-resistant Portland cement is prepared from high-iron and low-calcium cement clinker mineral components, auxiliary functional components, auxiliary gelling components, and industrial gypsum. The above-mentioned components are : 80% high-iron and low-calcium cement clinker mineral components, 5% auxiliary functional components, 10% auxiliary gelling components, and 5% industrial gypsum (produced by separate grinding, joint mixing and grinding, etc.).

[0031] The auxiliary function component is layered magnesium aluminum double metal hydroxide. The auxiliary gelling component is slag powder and fly ash, the slag powder and fly ash are mixed at a mass ratio of 1:1, and the specific surface area is 450m 2 / kg. The industrial gypsum is desulfurized gypsum.

[0032] The mineral components of the high-iron and low-calcium cement clinker are mainly prepared from high-iron and low-calcium Portland cement clinker and high-iron and low-calci...

Embodiment 2

[0042] A high-early-strength, high-corrosion-resistant Portland cement is prepared from high-iron and low-calcium cement clinker mineral components, auxiliary functional components, auxiliary gelling components, and industrial gypsum. The above-mentioned components are : High iron and low calcium cement clinker mineral components 77%, auxiliary functional components 3%, auxiliary gelling components 15%, industrial gypsum 5% (produced by separate grinding, joint mixing grinding and other processes).

[0043] The auxiliary function component is layered magnesium-iron double metal hydroxide. The auxiliary gelling component is slag fine powder and fly ash, the slag fine powder and fly ash are mixed at a mass ratio of 1:1, and the specific surface area is not less than 500m 2 / kg. The industrial gypsum used is desulfurized gypsum.

[0044] The mineral components of the high-iron and low-calcium cement clinker are mainly prepared from high-iron and low-calcium Portland cement clin...

Embodiment 3

[0056] A high-early-strength, high-corrosion-resistant Portland cement is prepared from high-iron and low-calcium cement clinker mineral components, auxiliary functional components, auxiliary gelling components, and industrial gypsum. The above-mentioned components are : High iron and low calcium cement clinker mineral component 60%, auxiliary functional component 10%, auxiliary gelling component 25%, industrial gypsum 5% (produced by separate grinding, joint mixing grinding and other processes).

[0057] The auxiliary function component is layered magnesium-iron double metal hydroxide. The auxiliary gelling component is silica fume and slag micropowder, the mass ratio of silica fume and slag micropowder is 1:1, and its specific surface area is not less than 1000m 2 / kg. The industrial gypsum is a mass ratio mixture of salt gypsum and desulfurized gypsum.

[0058] The mineral components of the high-iron and low-calcium cement clinker are mainly prepared from high-iron and low-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com