Low-heat high-corrosion-resistance Portland cement and preparation method thereof

A Portland cement, high-resistance technology, applied in the field of materials, can solve the problems of affecting the stability of cement or cementitious materials, reducing the early strength of cement-based materials, and unfavorable resistance to sulfate erosion, so as to achieve easy control of production quality and excellent Anti-erosion performance, effect of shortening curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 65.53 parts of limestone, 20.57 parts of clay, 5.08 parts of slag, mineralizer (CaF 2 with P 2 o 5 mixed) 2.5 parts, stabilizer (steel slag mixed with zinc slag) 3.5 parts, activator (sphalerite and V 2 o 5 mix) 2.28 parts.

[0027] 1) Grinding each raw material and transporting it into the homogenization warehouse for homogenization;

[0028] 2) Transport to the suspension preheater and the calciner, the temperature of the calciner is 850-870°C;

[0029] 3) Transfer to a rotary kiln for calcination, wherein the kiln body rotation speed is 3.2-3.5rpm, the grate cooler push rod speed is 9-17 times / min, and the calcination temperature is 1250°C.

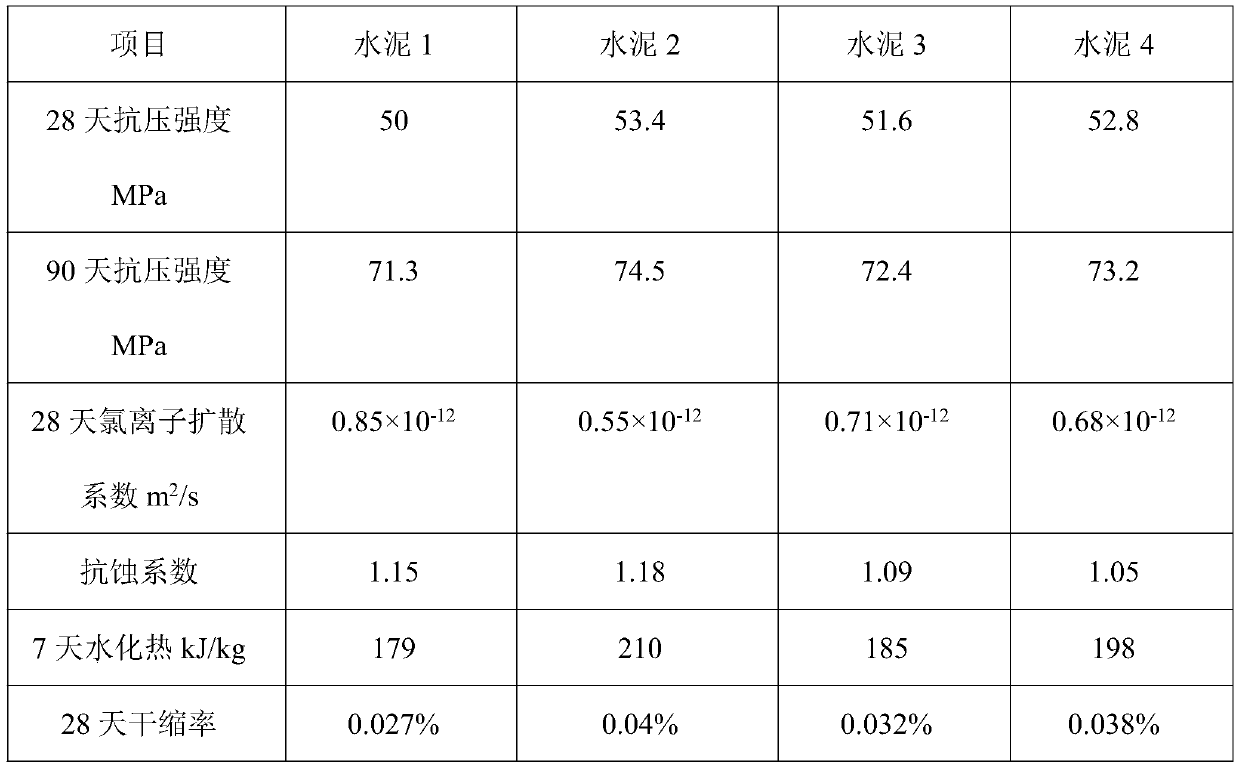

[0030] Determine the setting time of cement according to GB / T 1346-2011 standard; test the 28-day and 90-day strength according to GB / T17671-1999 standard; measure the chloride ion diffusion coefficient according to JC / T1086, and measure the corrosion resistance coefficient according to GB / T 749-2008 ; Measure its heat of ...

Embodiment 2

[0032] 67.53 parts of limestone, 23.57 parts of clay, 3.08 parts of slag, mineralizer (CaF 2 with SO 3 Mixing) 2.5 parts, stabilizer (gypsum mixed with zinc slag) 1.5 parts, activator (sphalerite and MnO 2 mix) 1.82 parts.

[0033] 1) Grinding each raw material and transporting it into the homogenization warehouse for homogenization;

[0034] 2) Transport to the suspension preheater and the calciner, the temperature of the calciner is 850-870°C;

[0035] 3) Transfer to a rotary kiln for calcination, wherein the kiln body rotation speed is 3.2-3.5rpm, the grate cooler push rod speed is 9-17 times / min, and the calcination temperature is 1275°C.

[0036] Determine the setting time of cement according to GB / T 1346-2011 standard; test the 28-day and 90-day strength according to GB / T17671-1999 standard; measure the chloride ion diffusion coefficient according to JC / T1086, and measure the corrosion resistance coefficient according to GB / T 749-2008 ; Measure its heat of hydration ...

Embodiment 3

[0038] 66.43 parts of limestone, 21.57 parts of clay, 3.08 parts of slag, mineralizer (CaF 2 with CaCl 2 Mixing) 3 parts, stabilizer (gypsum mixed with copper slag) 3.5 parts, activator (sphalerite and MnO 2 mix) 2.42 parts.

[0039] 1) Grinding each raw material and transporting it into the homogenization warehouse for homogenization;

[0040] 2) Transport to the suspension preheater and the calciner, the temperature of the calciner is 850-870°C;

[0041]3) Transfer to a rotary kiln for calcination, wherein the kiln body rotation speed is 3.2-3.5rpm, the grate cooler push rod speed is 9-17 times / min, and the calcination temperature is 1325°C.

[0042] Determine the setting time of cement according to GB / T 1346-2011 standard; test the 28-day and 90-day strength according to GB / T17671-1999 standard; measure the chloride ion diffusion coefficient according to JC / T1086, and measure the corrosion resistance coefficient according to GB / T 749-2008 ; Measure its heat of hydration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com