Assembled embedded type prefabricated hollow underground continuous wall and construction method thereof

A hollow, buried technology, applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of long construction period and unguaranteed construction quality of cast-in-place underground diaphragm walls, and reduce water and mud inrush. The effect of reducing the probability of accidents, reducing the difficulty of construction and hoisting, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

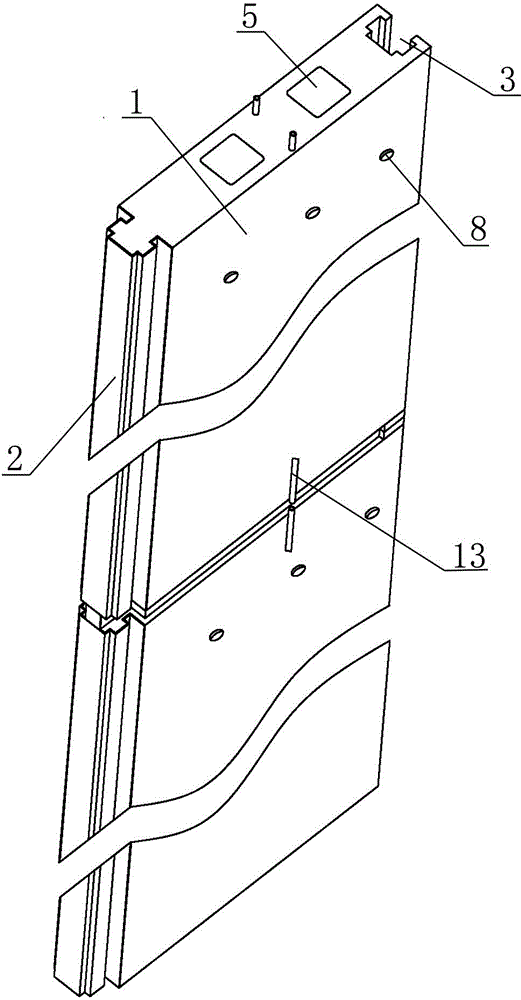

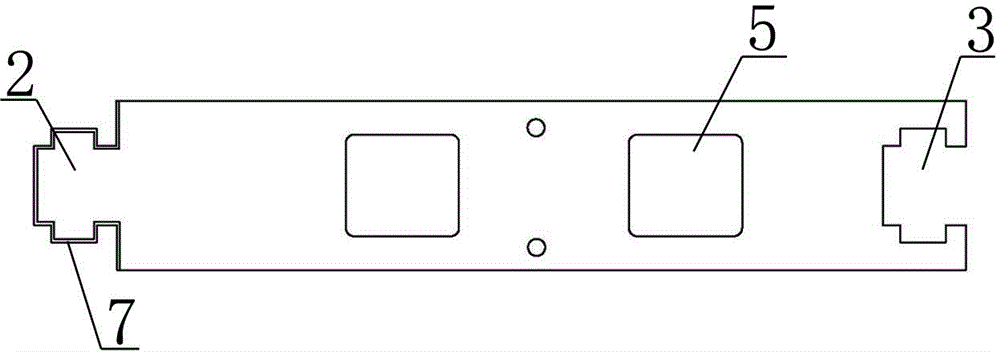

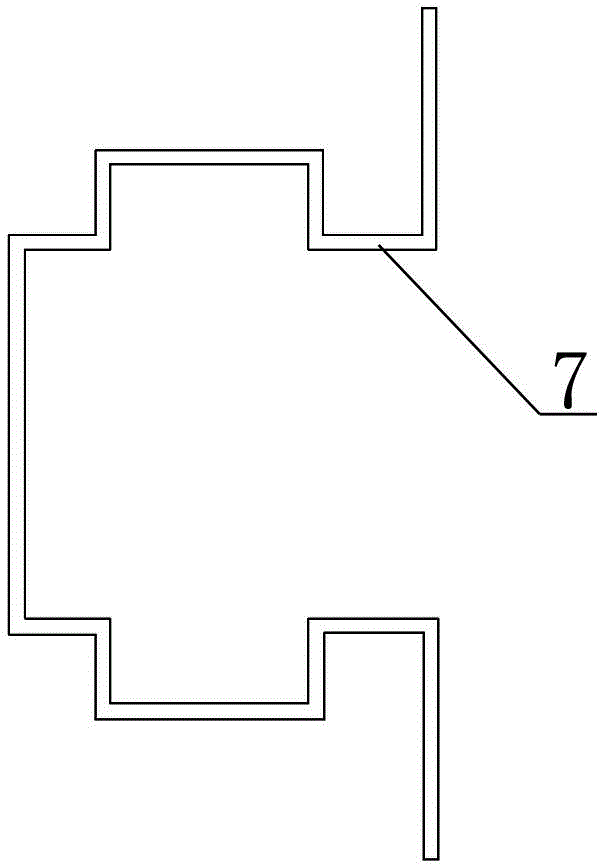

[0046] Examples see Figure 1 to Figure 5 As shown, an embedable prefabricated hollow underground continuous wall is formed by splicing several wall units. The wall unit includes a wall unit body 1, an upper connection assembly and a lower connection assembly. The wall The unit body 1 is a hollow block with a tenon 2 on the left side. The transverse end surface of the tenon 2 is a rectangle with a side wall protruding outward, and the right side is a groove. The shape of the tenon and the groove is completely Matching, the two are plugged together to form a tongue-and-groove connection. The upper connection assembly is composed of the same right side open groove body as the lateral end surface of the wall unit body 1, a backing plate 11 and two L-shaped connection blocks 12. The open groove The body is surrounded by connecting steel plates 9 with bolt holes, and its opening is connected with two L-shaped connecting blocks 12. The height of the L-shaped connecting blocks 12 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com