Concrete mixing grout transporting equipment

A technology for transportation equipment and concrete, which is applied in the field of concrete mixing and grouting transportation equipment, can solve the problems of failure to achieve the use effect, unscientific valve body design, troublesome installation and maintenance, etc., to improve project quality and construction progress, save labor, Easy-to-clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

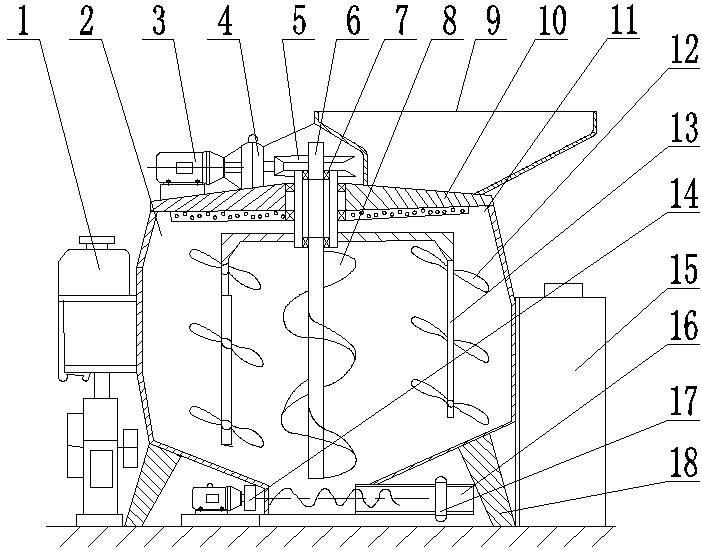

[0029] See attached figure 1 As shown, on the construction site, select an empty space as a temporary stock yard. By opening the mixing chamber door 10, raw materials such as sand, stone, cement and water are put into the mixing chamber 2 from the hopper 9 in proportion to start the power system 1 power supply, the mixing main shaft 6 rotates and drives the two mixing secondary shafts 13 to rotate. In the continuous rotation of the propeller 8 and the mixing blade 12, the input raw materials are evenly mixed into finished concrete, and the propeller 14 continues to reciprocate In the process, the finished concrete is continuously transported along the discharge pipe 16 to the construction site.

Embodiment 2

[0031] See attached Figure 4 As shown, it is only necessary to select an open space as a temporary stock yard, fix the concrete mixing and grouting transportation equipment on the transportation trolley 27, open the mixing chamber door 10, and transfer the raw materials such as sand, stone, cement and water from the hopper 9 in proportion Put into the mixing chamber 2 and start the power supply of the power system 1, the mixing main shaft 6 rotates and drives the two mixing secondary shafts 13 to rotate. In the continuous rotation of the propeller 8 and the mixing blade 12, the input raw materials are evenly mixed into finished concrete , The mobile transport trolley 27 moves to the closer construction site where the finished concrete is needed. During the traveling of the mobile transport trolley 27, the equipment also starts the mixing mechanism while walking. After reaching the construction site, the propeller 14 is activated. In the continuous reciprocating movement of 14, ...

Embodiment 3

[0033] See attached Figure 5 As shown, it is only necessary to select an empty space as a temporary stock yard, fix the concrete mixing and grouting transportation equipment on the transport truck 28, open the mixing chamber door 10, and transfer the raw materials such as sand, stone, cement and water from the hopper 9 in proportion Put into the mixing chamber 2 and start the power supply of the power system 1, the mixing main shaft 6 rotates and drives the two mixing secondary shafts 13 to rotate. In the continuous rotation of the propeller 8 and the mixing blade 12, the input raw materials are evenly mixed into finished concrete , Start the transport vehicle 28 to move to the remote construction site where the finished concrete is needed. When the transport vehicle 28 is walking, the equipment also starts the mixing mechanism while walking. After arriving at the construction site, it starts the propeller 14 and the propeller 14 In the continuous reciprocating movement of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com