Patents

Literature

33 results about "Longitudinal contraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Longitudinal contraction joints are formed by sawing the hardened concrete or by forming grooves in the fresh concrete, much in the same way as transverse contrac tion joints, however the depth of the saw cut or groove should be one-third the slab thickness (D/3).

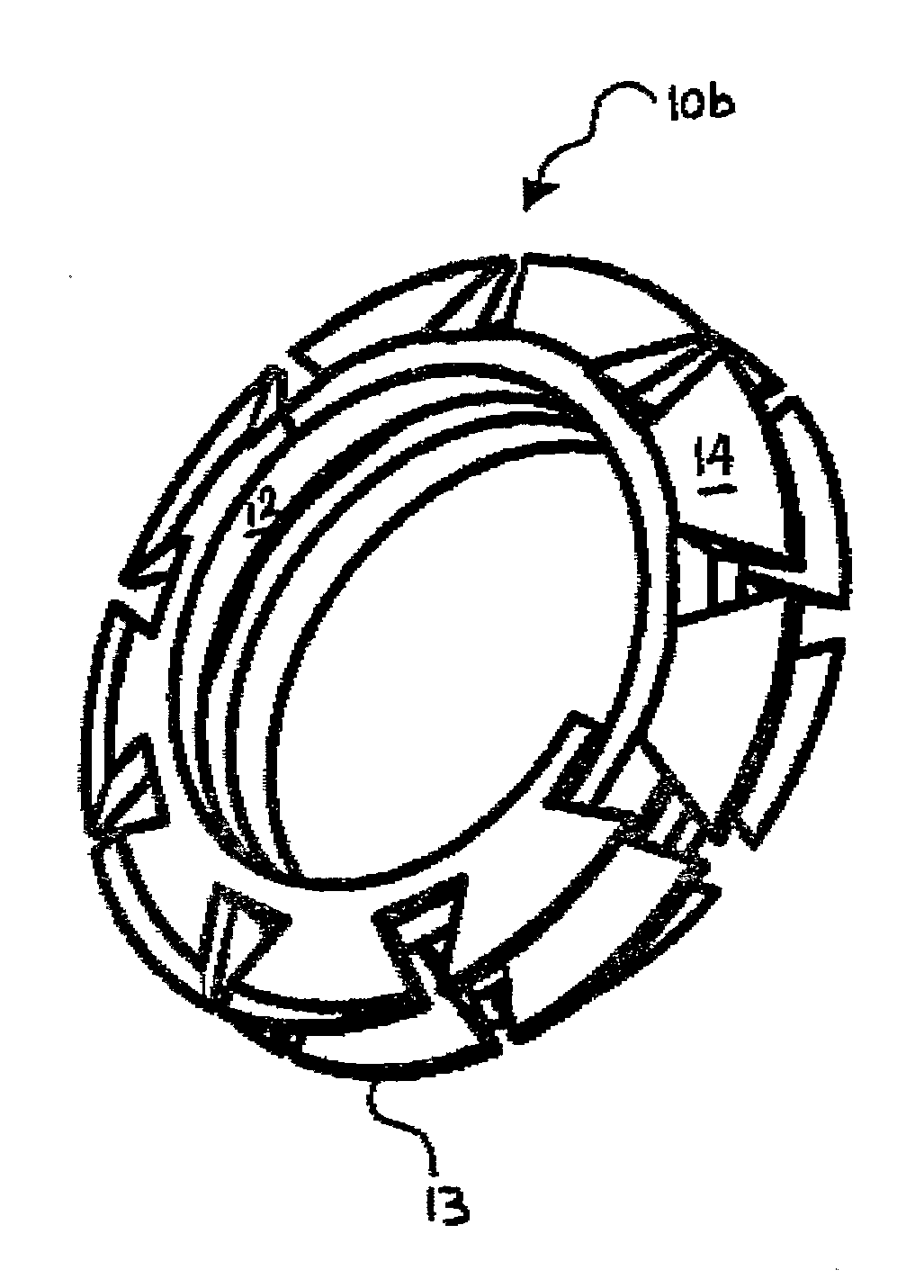

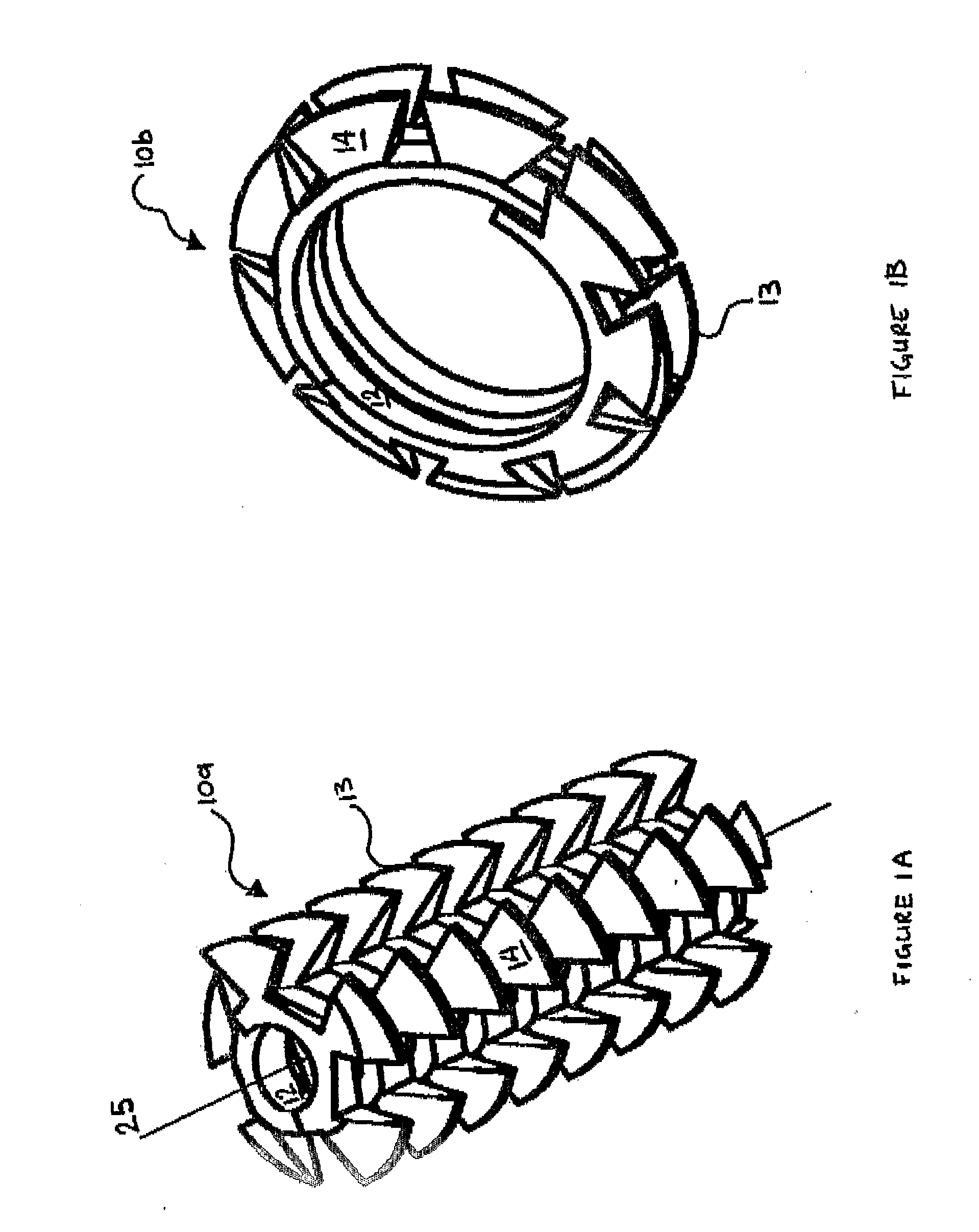

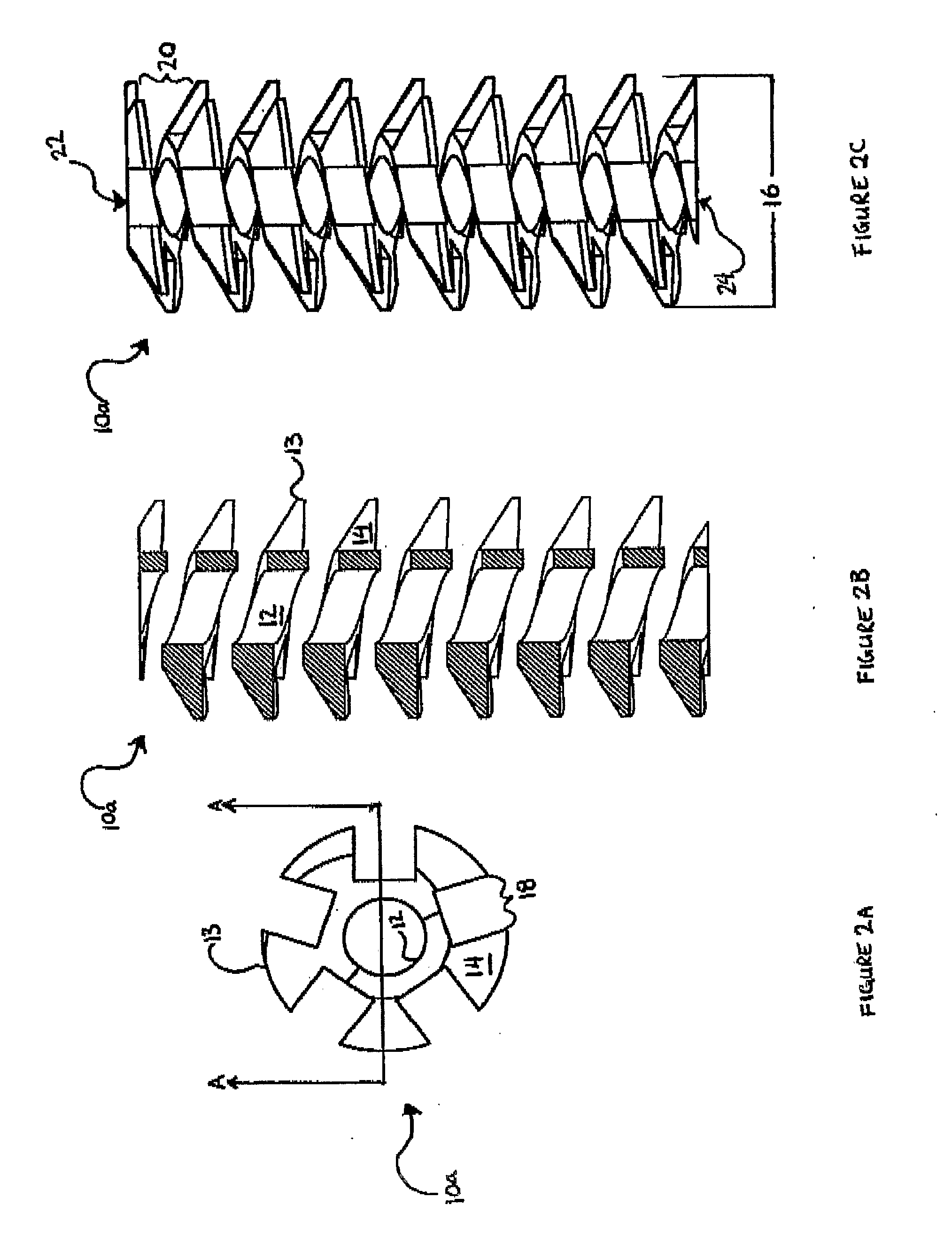

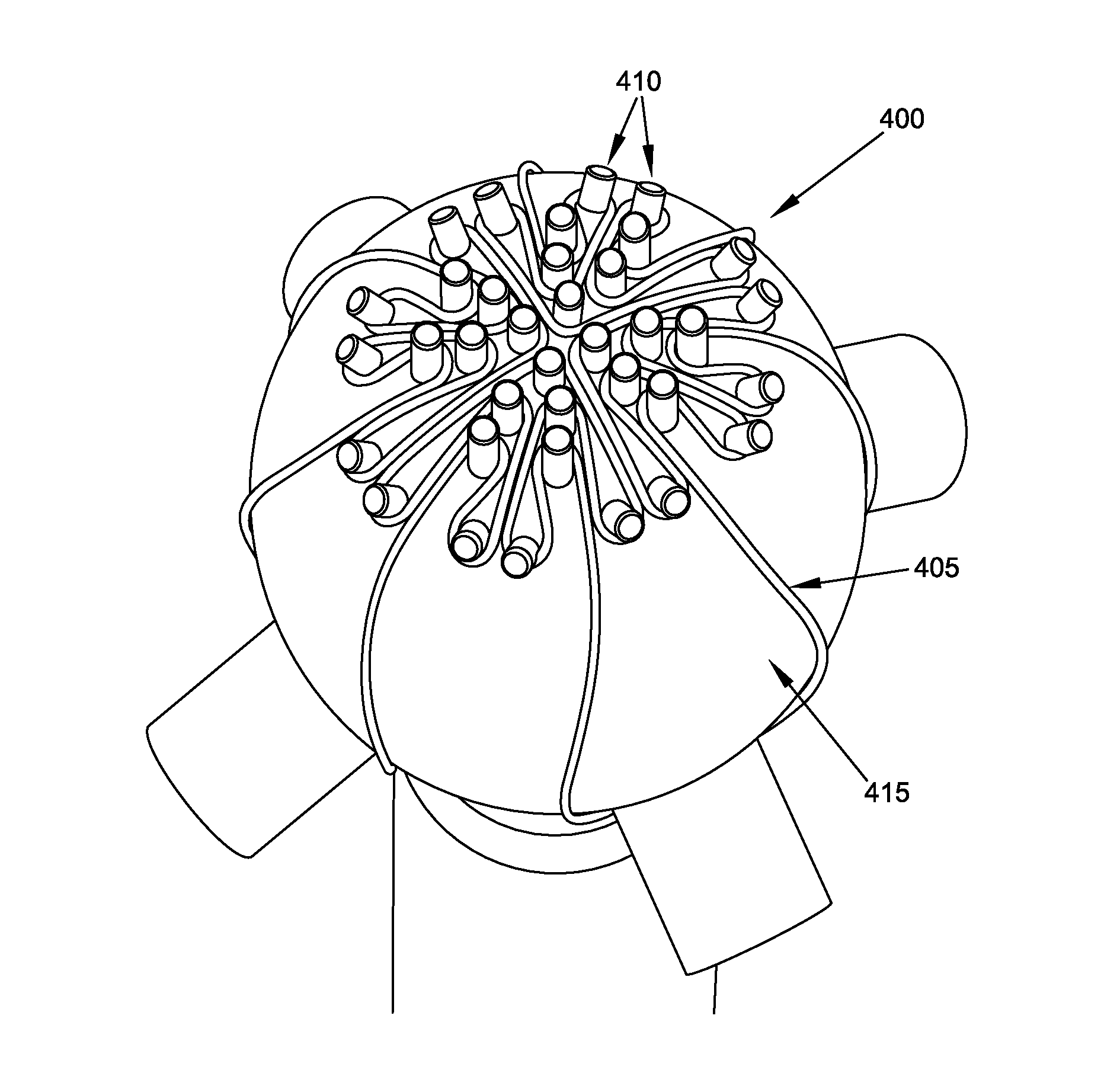

Orthopaedic Helical Coil Fastener and Apparatus and Method for Implantation Thereof

InactiveUS20080195096A1Improve scalabilityFacilitate bone ingrowthInternal osteosythesisBone implantLongitudinal contractionHelical coil

Provided herein is an implantable device and an expansion apparatus, method and system for implantation of the implantable device. In some embodiments, the device may include a helical coil having a contracted state, adapted for radial expansion and longitudinal contraction to an expanded state. The helical coil in the contracted state is adapted for positioning at a target site having walls defining an opening and is operable to engage the walls of the opening at said target site in the expanded state. The helical coil may also have an inner surface proximal to the longitudinal axis of the helical coil and an outer surface distal to the longitudinal axis of the helical coil, wherein the inner surface is operable to engage a fastener in the expanded state and wherein the outer surface defines a plurality of teeth extending radially outward to engage the walls of the target site.

Owner:FREI HANSPETER

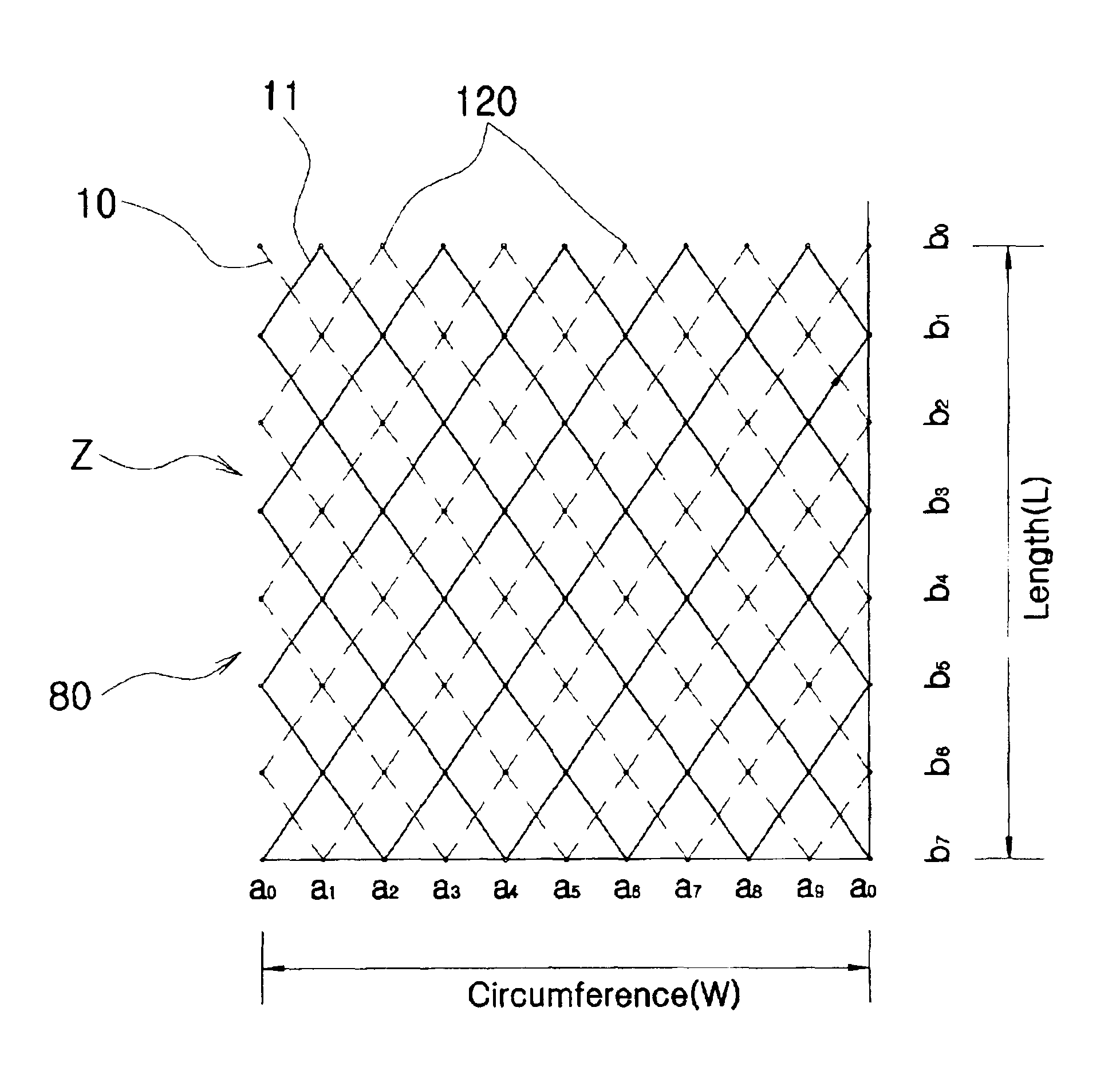

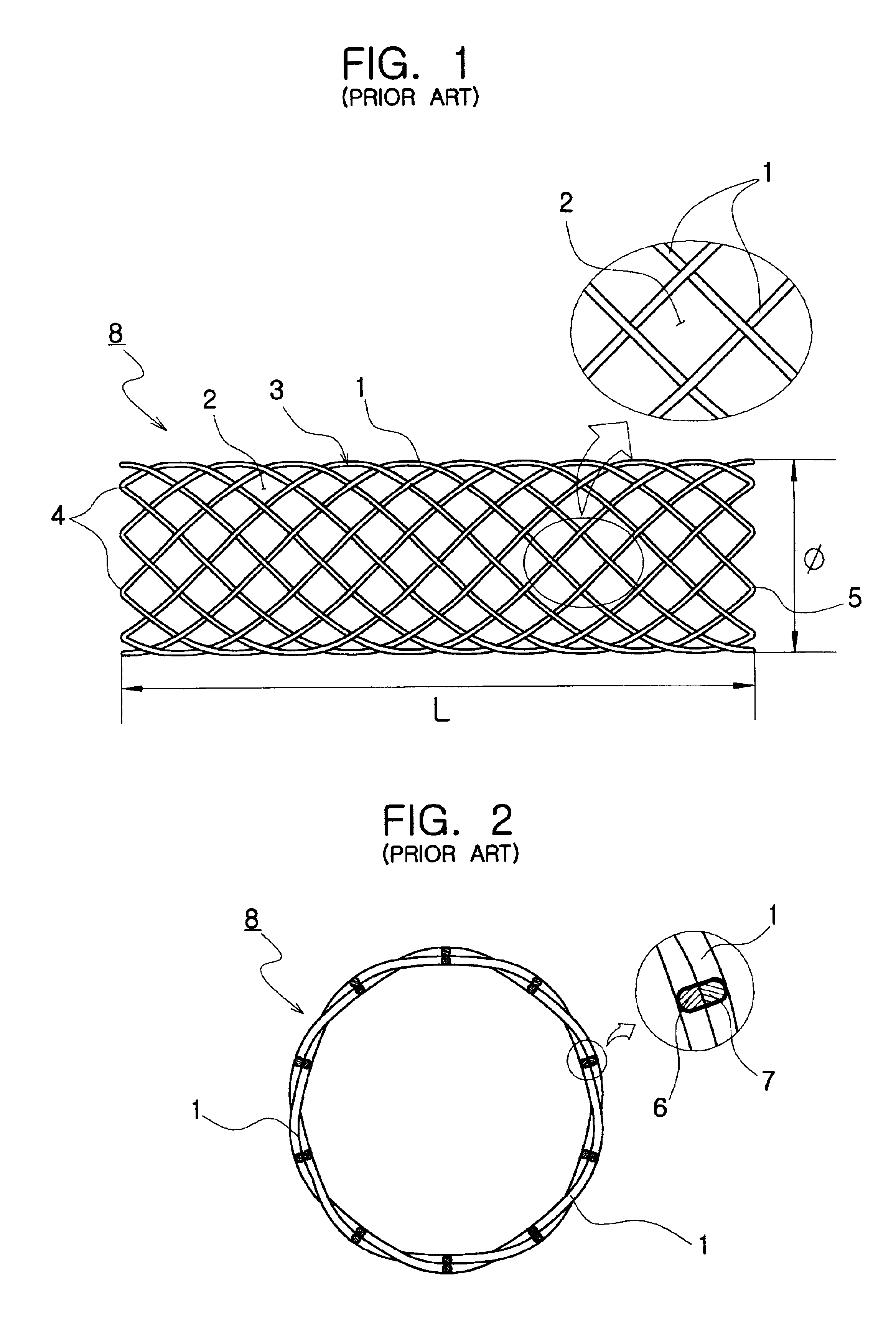

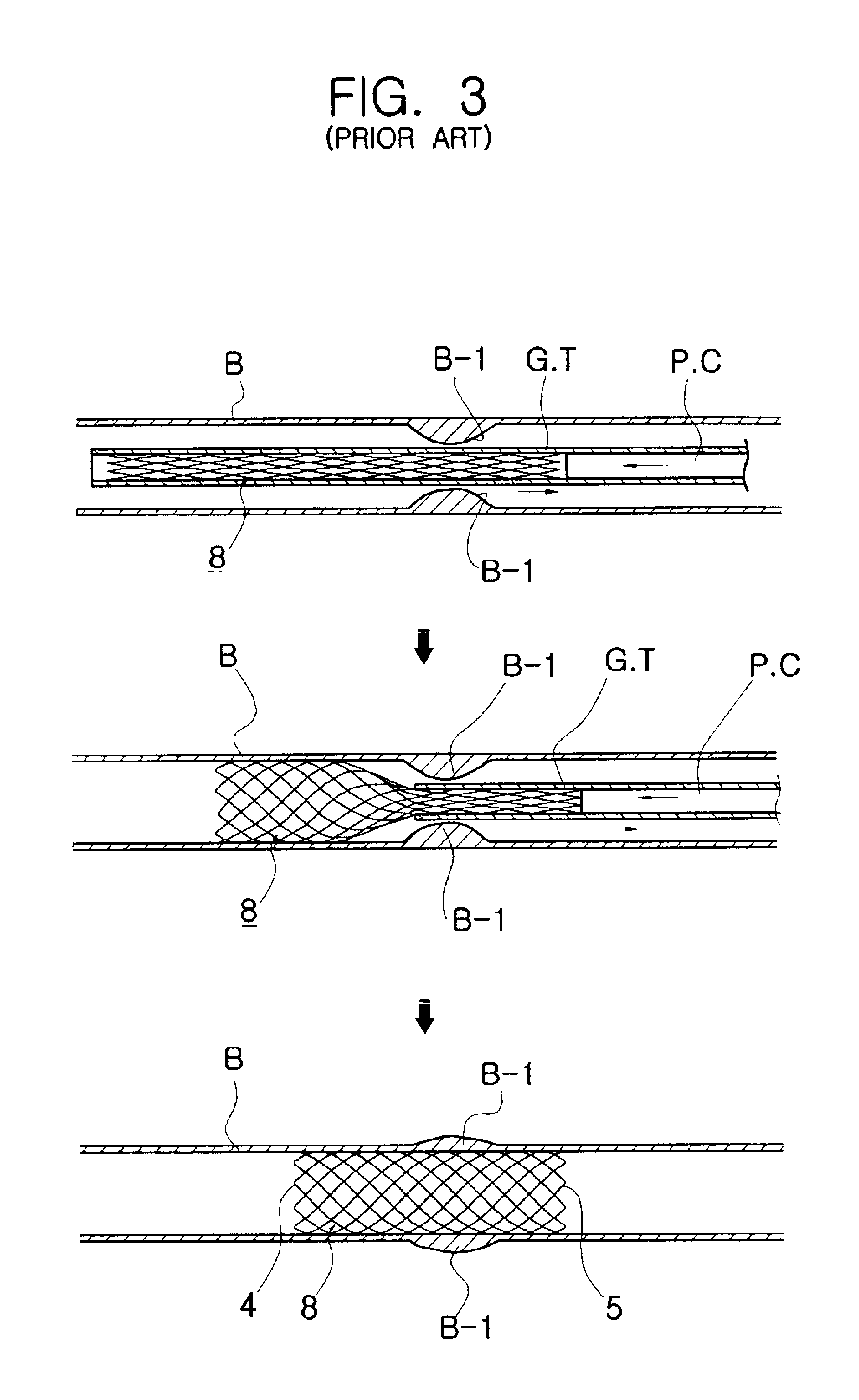

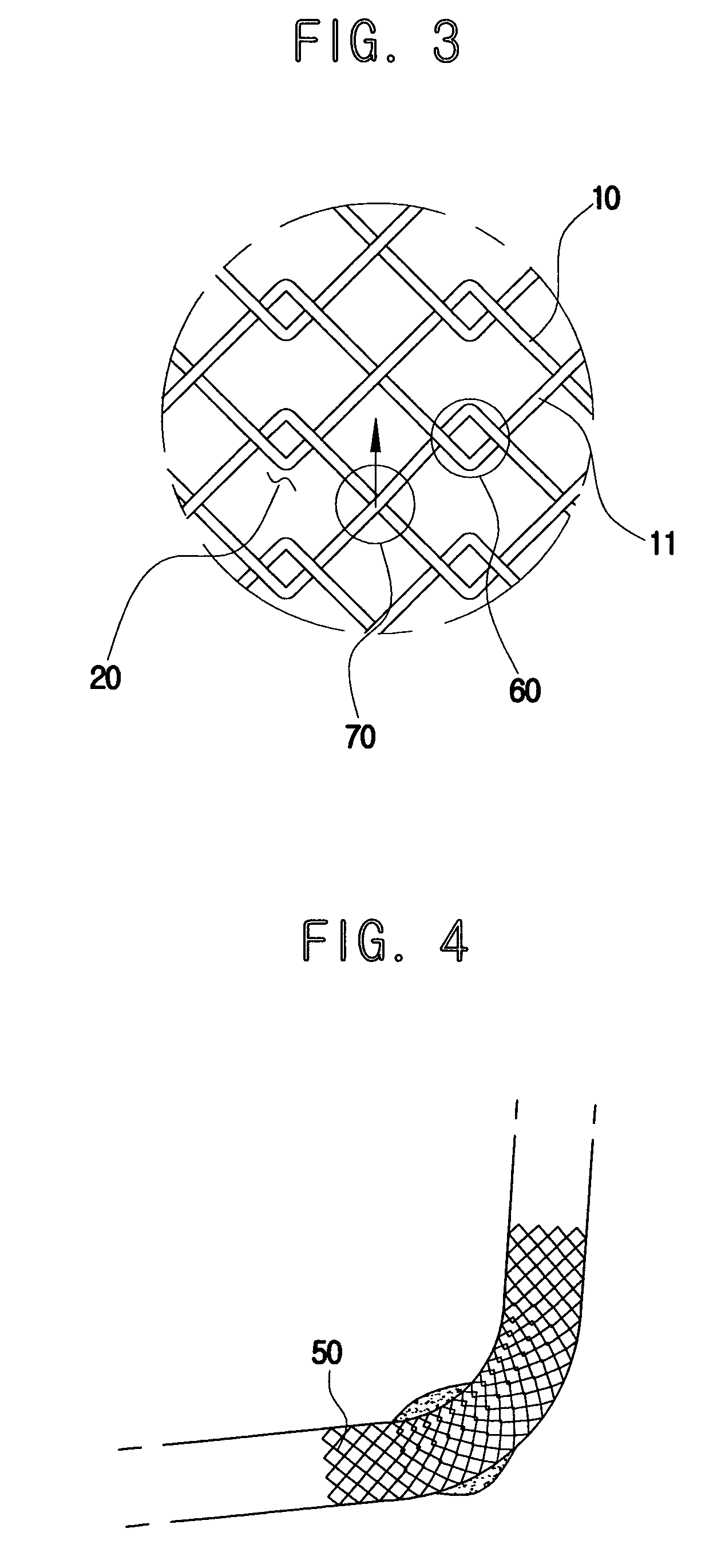

Flexible self-expandable stent using shape memory alloy and method and apparatus for fabricating the same

Disclosed herein is a flexible self-expandable stent using shape memory alloy for expanding stenosal portions and method and apparatus for fabricating the same. The self-expandable stent using shape memory allow, comprises a first cylindrical stent member comprised of a first wire formed of super elastic shape memory alloy, the first wire being bent a large number of times while being extended upwardly and downwardly a large number of times, so the first wire forms a plurality of variable rhombic spaces by forming a plurality of intersections for causing the first wire to be intersected with itself to resist longitudinal constriction of the first cylindrical stent member and a plurality of interlocked points for causing the first wire to be interlocked with itself at spaced positions to allow longitudinal constriction of the first cylindrical stent member; and a second cylindrical stent member comprised of a second wire formed of super elastic shape memory alloy, the second wire being diagonally extended in parallel with the previously positioned first wire and passed alternately under and over the first wire so as to divide each of a plurality of rhombic spaces formed in the first cylindrical stent member into four equal parts, thereby preventing the first and second cylindrical stent members from being separated from each other.

Owner:TAEWOONG MEDICAL CO LTD

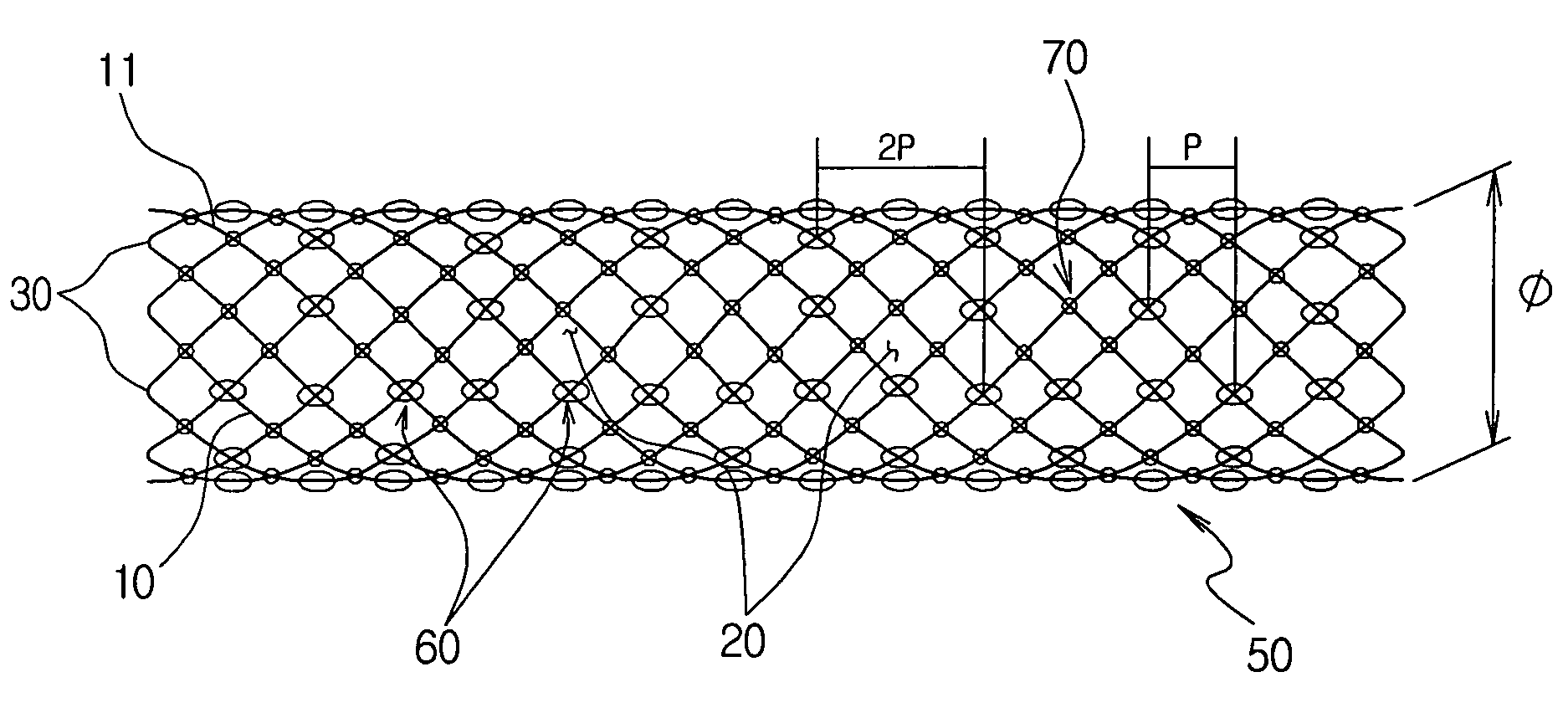

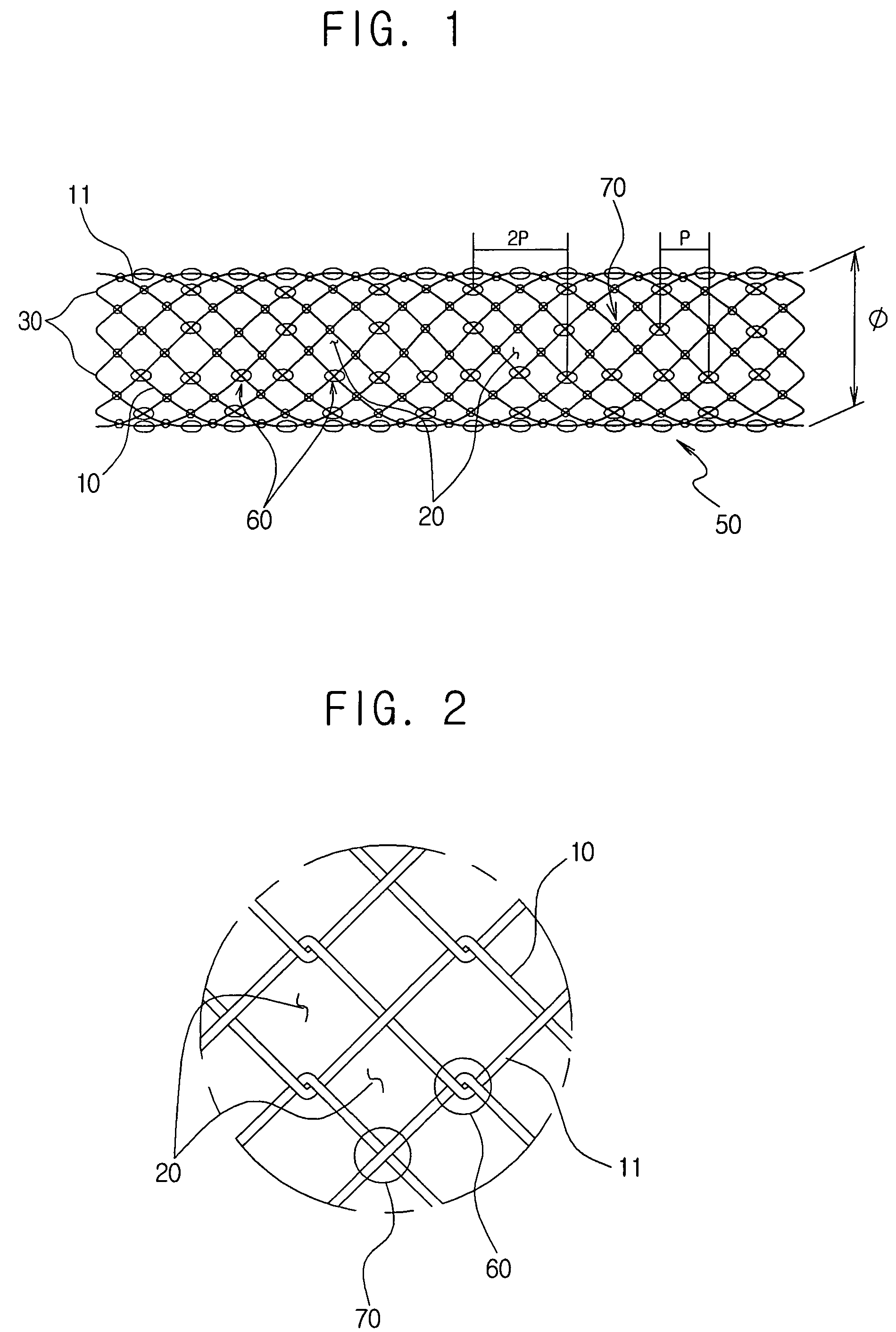

Flexible self-expandable stent and method of producing the same

ActiveUS7041126B2Prevents infiltration of tumorReliable maintenanceStentsSurgeryReticular formationLongitudinal contraction

A flexible self-expandable stent has inside and outside stent bodies each fabricated by knitting first and second super-elastic shape memory alloy wires into a net-like structure with the first wire zigzagged with a diagonal length P interlocked with the second wire zigzagged with a diagonal length 2P at a plurality of interlocked points with intersecting points therebetween to allow the stent bodies to apply force against longitudinal contraction of the stent bodies. The interlocked points and the intersecting points form a plurality of diamond-shaped meshes in the net-like structure of each stent body. A hollow rubber tube is closely fitted between the inside and outside stent bodies, with each of the overlapped ends of the rubber tube and the stent bodies being integrating into a single structure.

Owner:TAEWOONG MEDICAL CO LTD +1

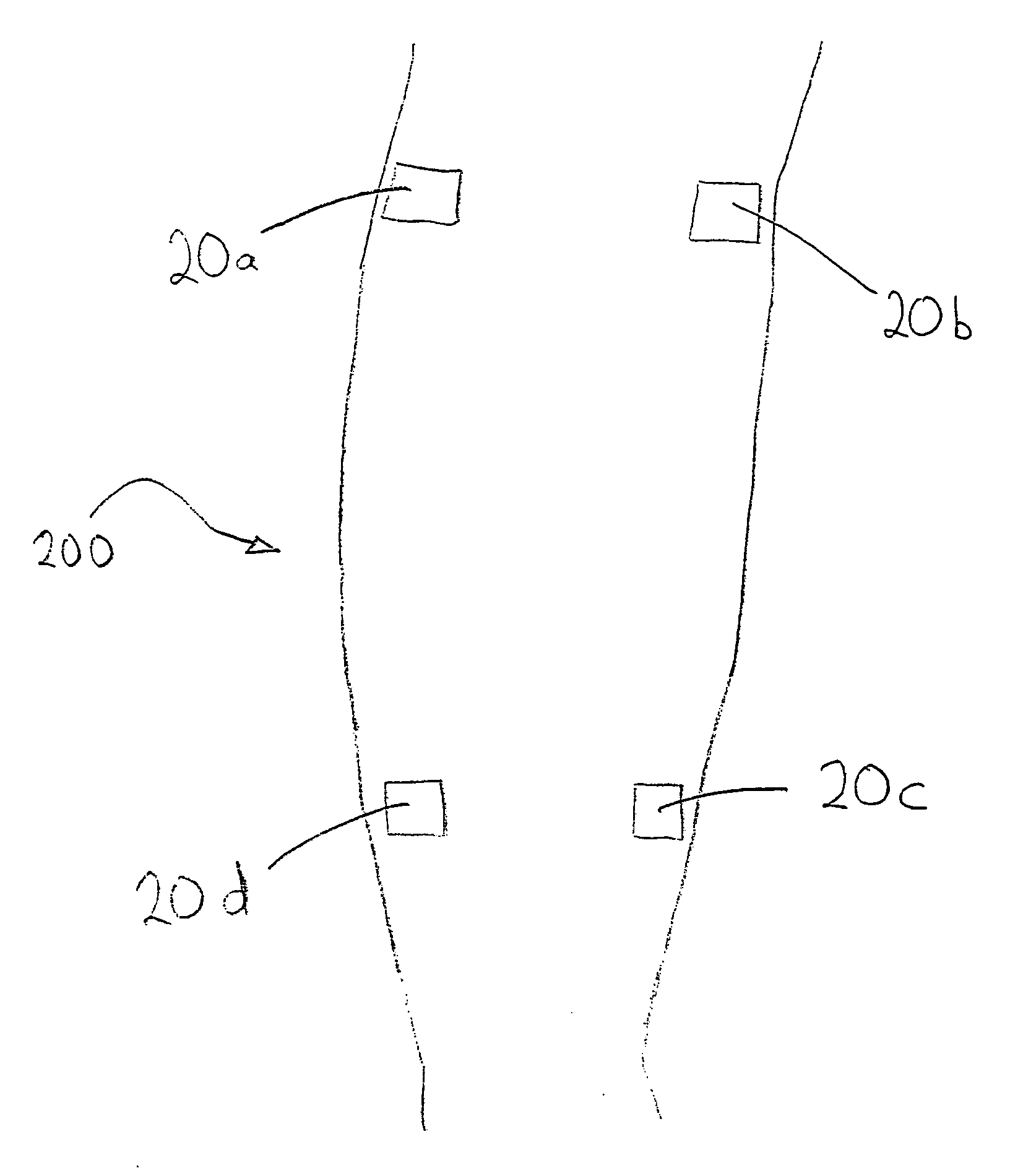

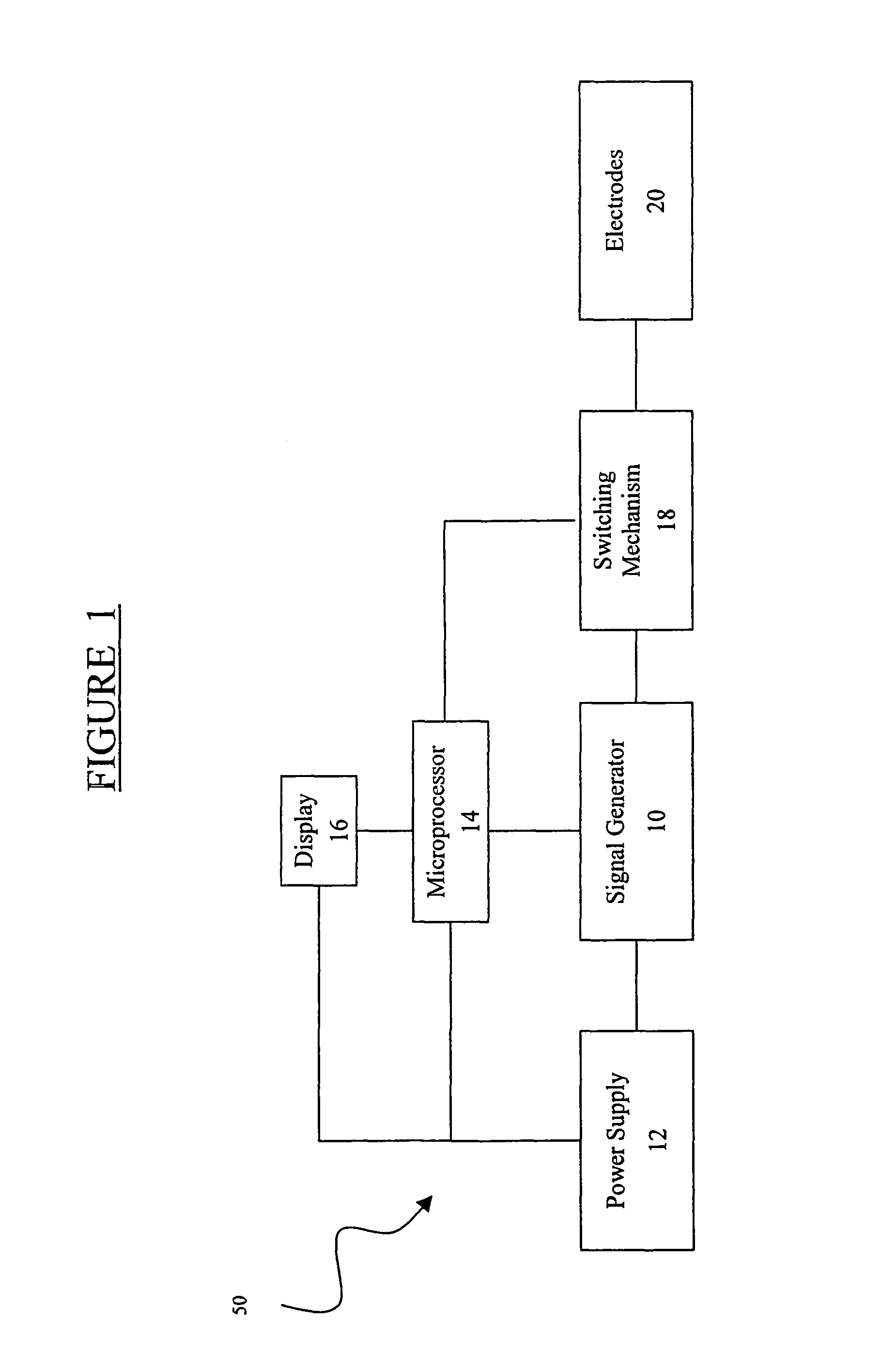

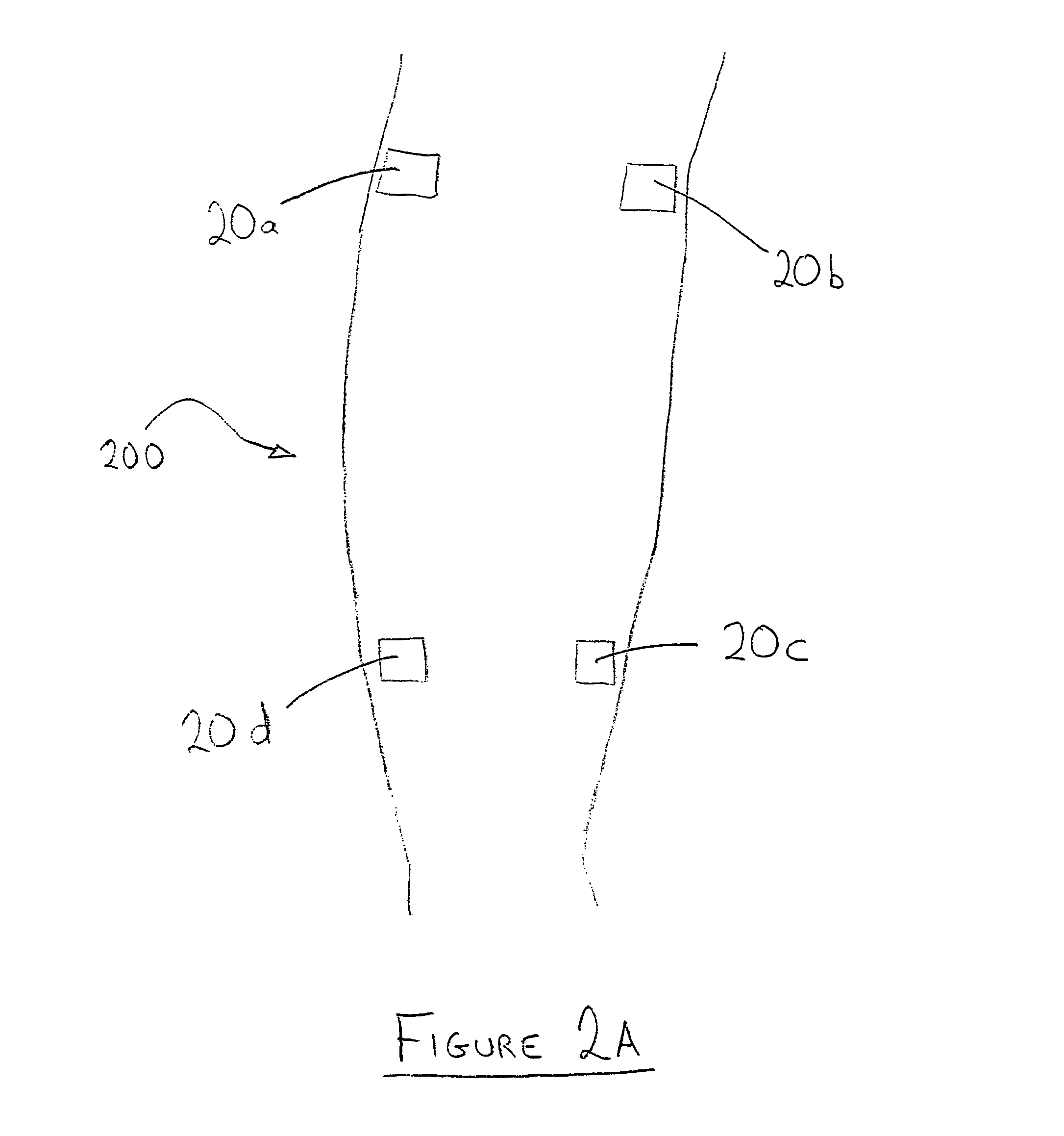

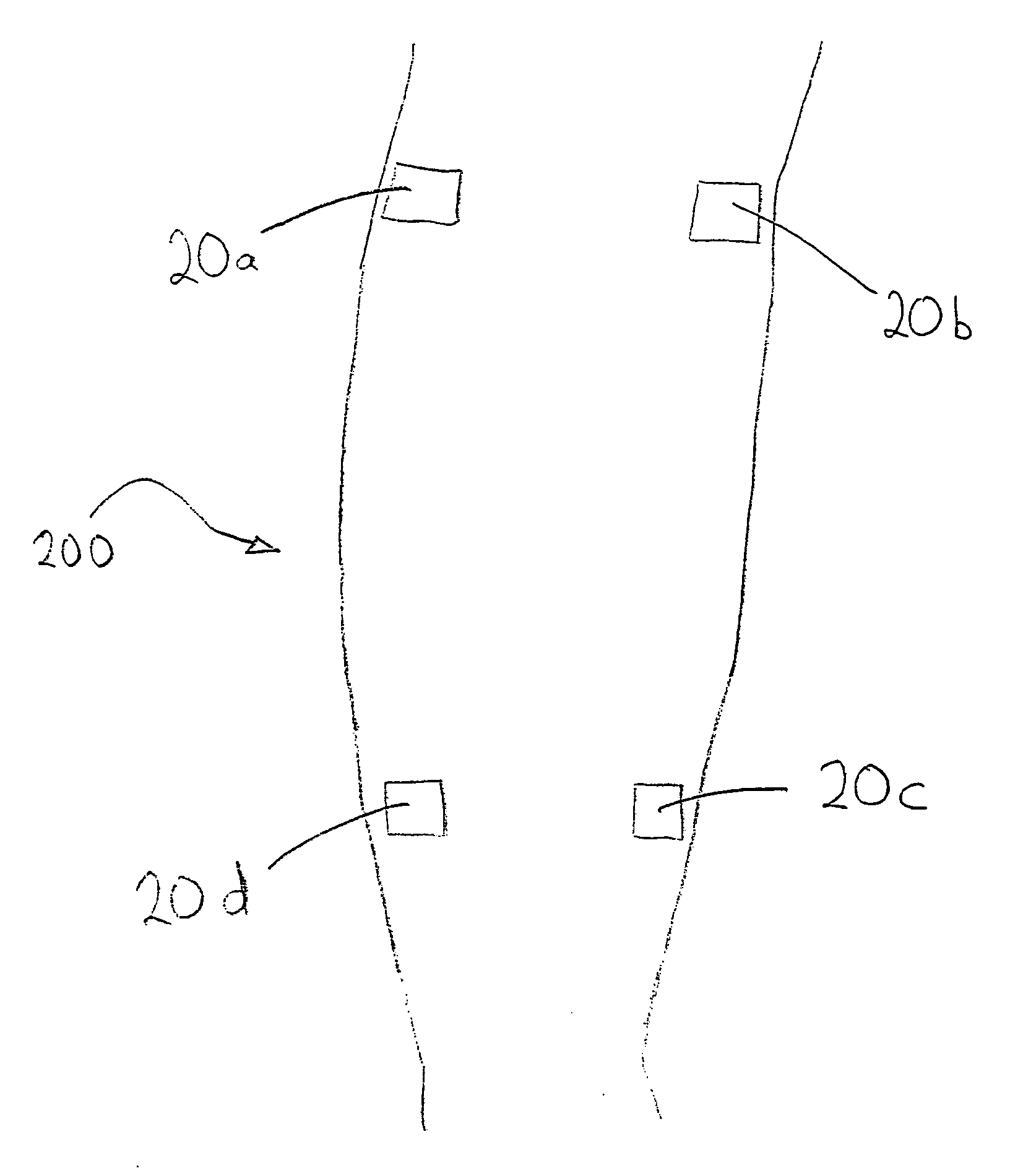

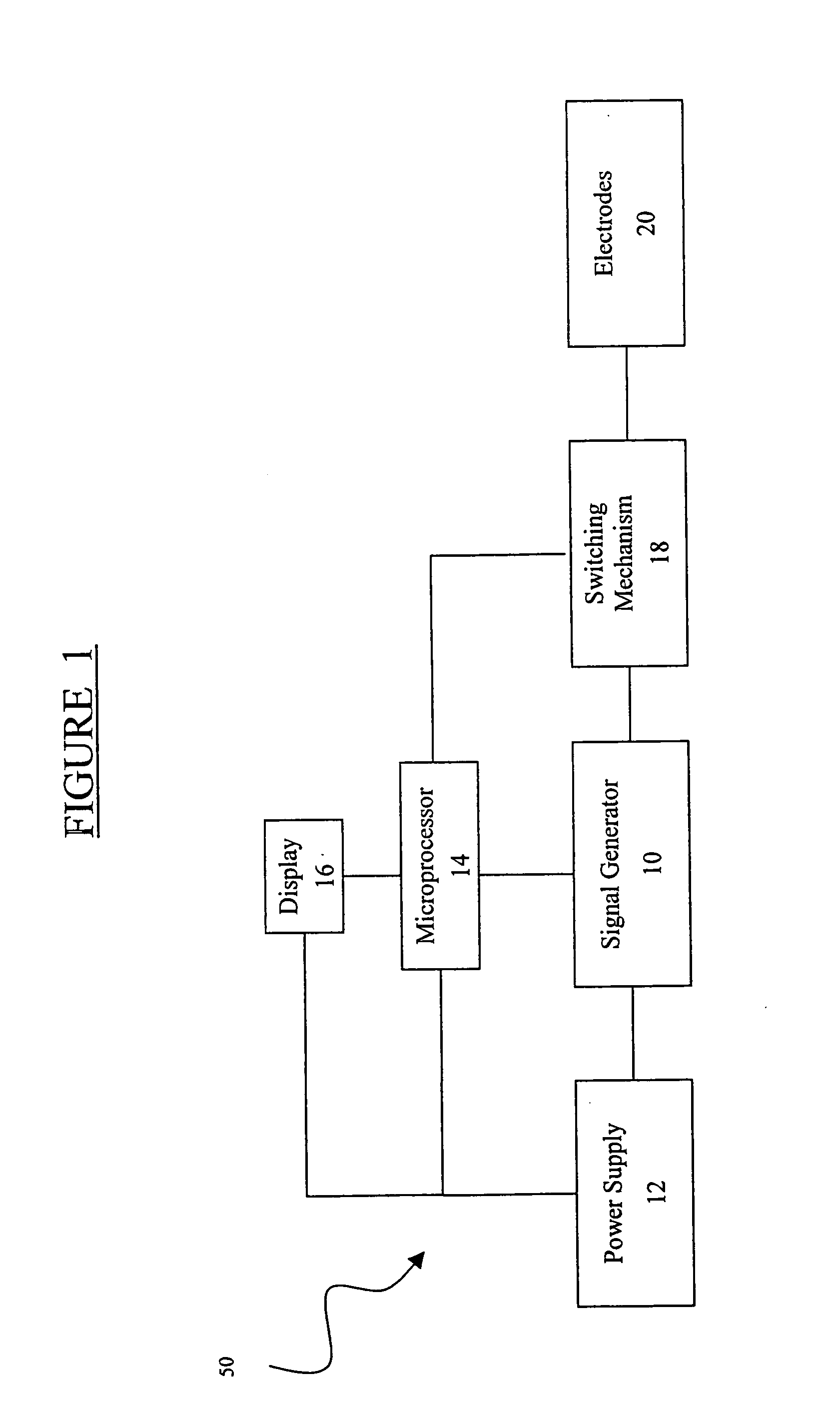

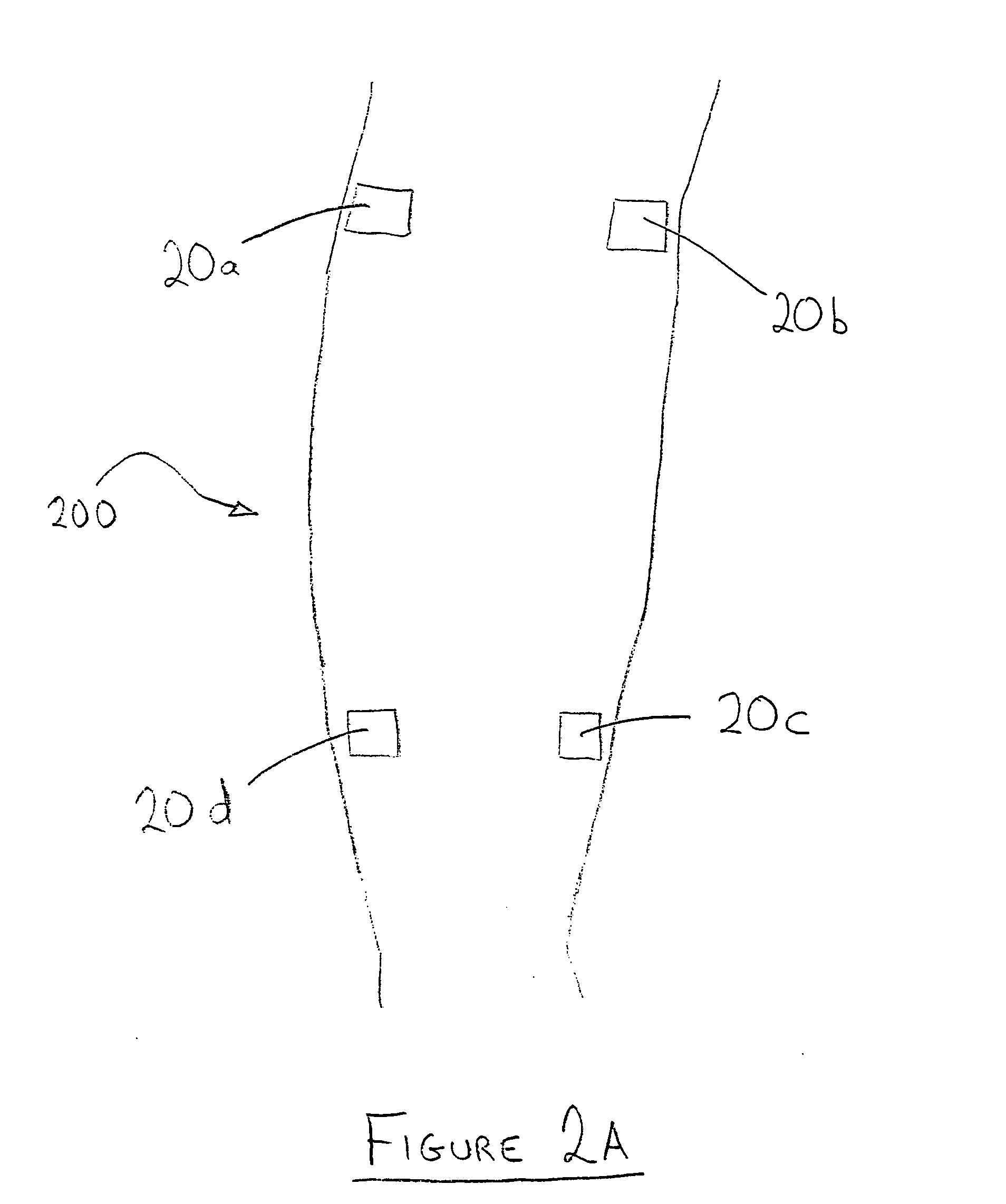

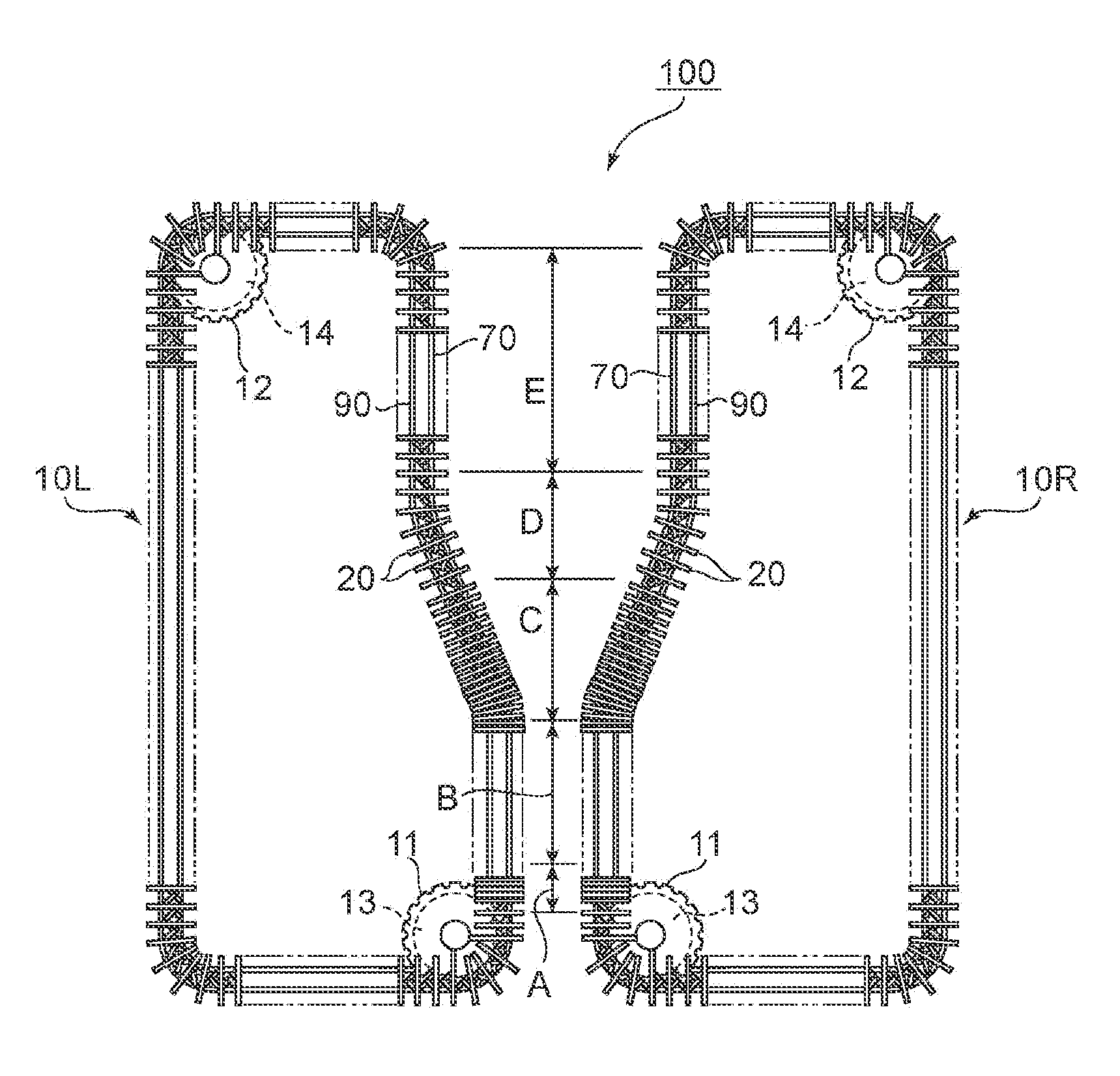

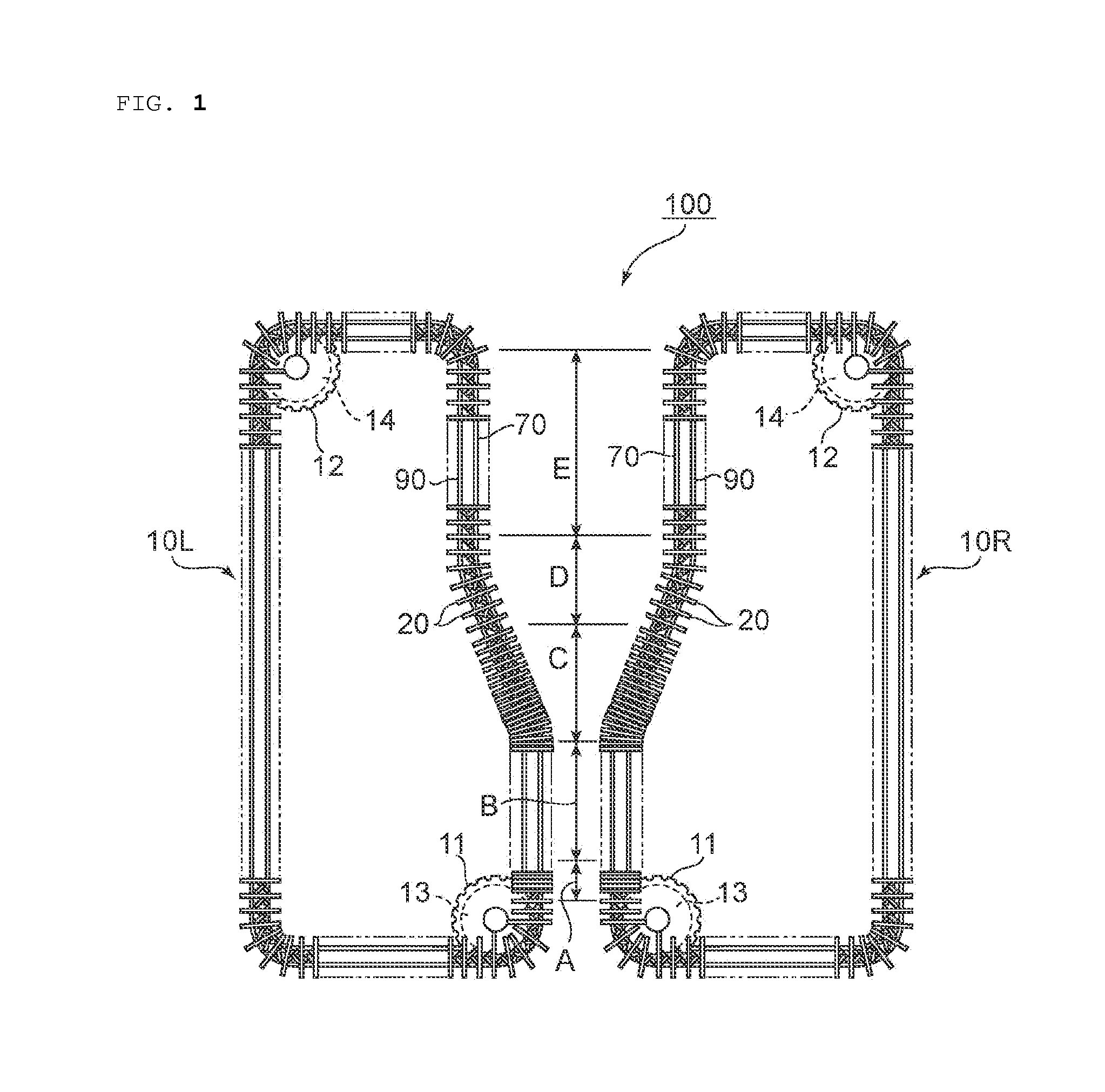

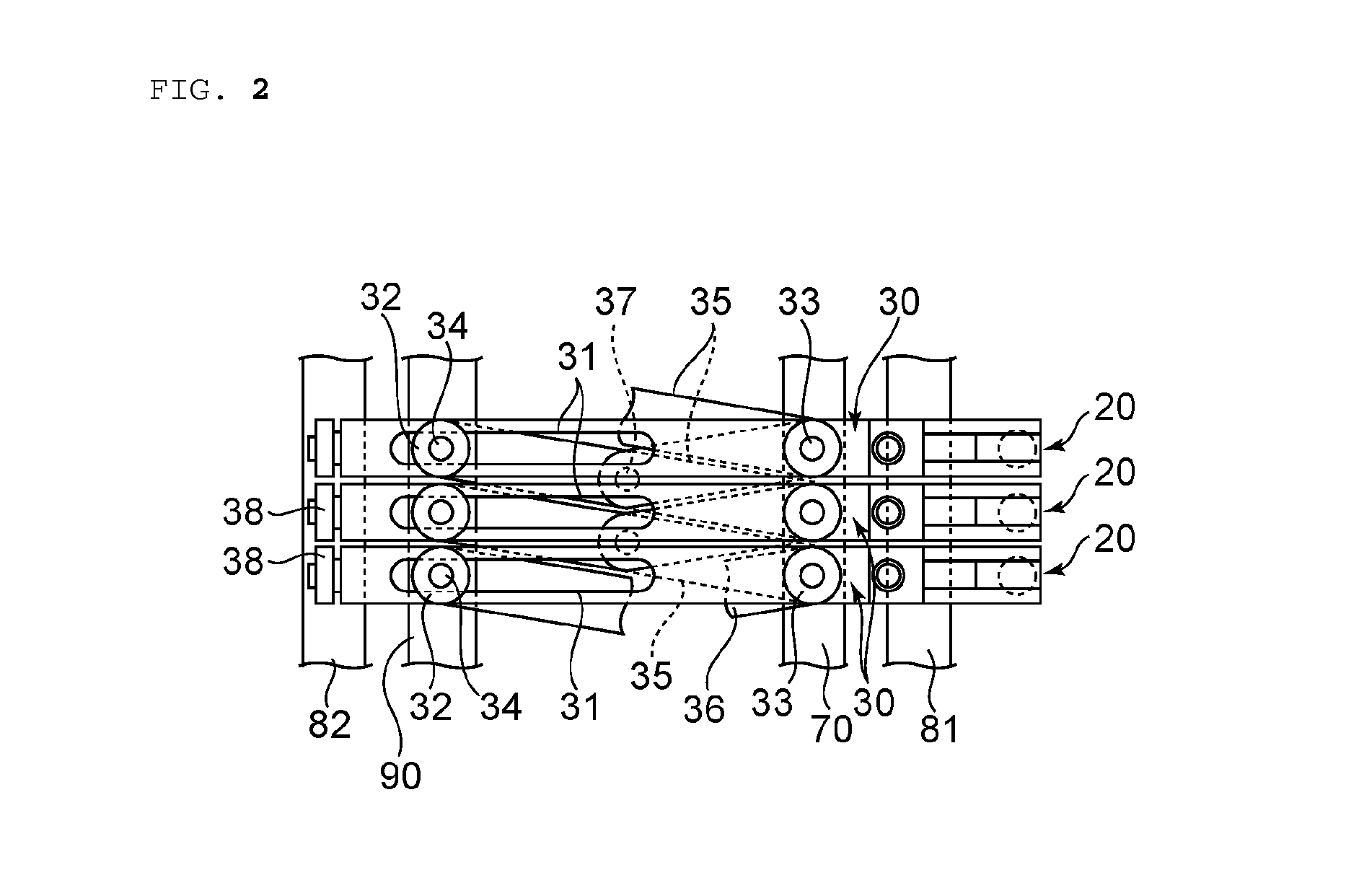

Method and device for enhanced blood flow

ActiveUS7991476B2Substantially painless, external, non-invasiveEasy to adaptElectrotherapyMuscle tissueElectrical impulse

A non-invasive method and device for promoting a localized change in a flow of blood through a limb segment by a series of electrically stimulated contractions of muscle tissue, the method including: (a) providing a device including: (i) at least a first electrode, a second electrode, and a third electrode, each of the electrodes for operatively contacting the limb segment of the body; (ii) a signal generator, operatively connected to each electrode, for producing a series of electrical impulses to the limb segment via the electrodes, and (iii) a control unit, associated with the signal generator, for controlling the signal generator so as to produce the series of electrical stimulation impulses; (b) positioning the plurality of electrodes on the limb segment; (c) applying electrical impulses to induce a substantially radial contraction of a first portion of the muscular tissue in the limb segment; (d) applying electrical impulses to induce a substantially longitudinal contraction of a second portion of the muscular tissue in the limb segment, such that the muscular tissue acts upon the blood vessel to produce the localized change in the flow of blood.

Owner:FLOWAID MEDICAL TECH CORP

Method and device for enhanced blood flow

ActiveUS20070270917A1Substantially painless, external, non-invasiveEasy to adaptElectrotherapyMuscle tissueControl signal

A non-invasive method and device for promoting a localized change in a flow of blood through a limb segment by a series of electrically stimulated contractions of muscle tissue, the method including: (a) providing a device including: (i) at least a first electrode, a second electrode, and a third electrode, each of the electrodes for operatively contacting the limb segment of the body; (ii) a signal generator, operatively connected to each electrode, for producing a series of electrical impulses to the limb segment via the electrodes, and (iii) a control unit, associated with the signal generator, for controlling the signal generator so as to produce the series of electrical stimulation impulses; (b) positioning the plurality of electrodes on the limb segment; (c) applying electrical impulses to induce a substantially radial contraction of a first portion of the muscular tissue in the limb segment; (d) applying electrical impulses to induce a substantially longitudinal contraction of a second portion of the muscular tissue in the limb segment, such that the muscular tissue acts upon the blood vessel to produce the localized change in the flow of blood.

Owner:FLOWAID MEDICAL TECH CORP

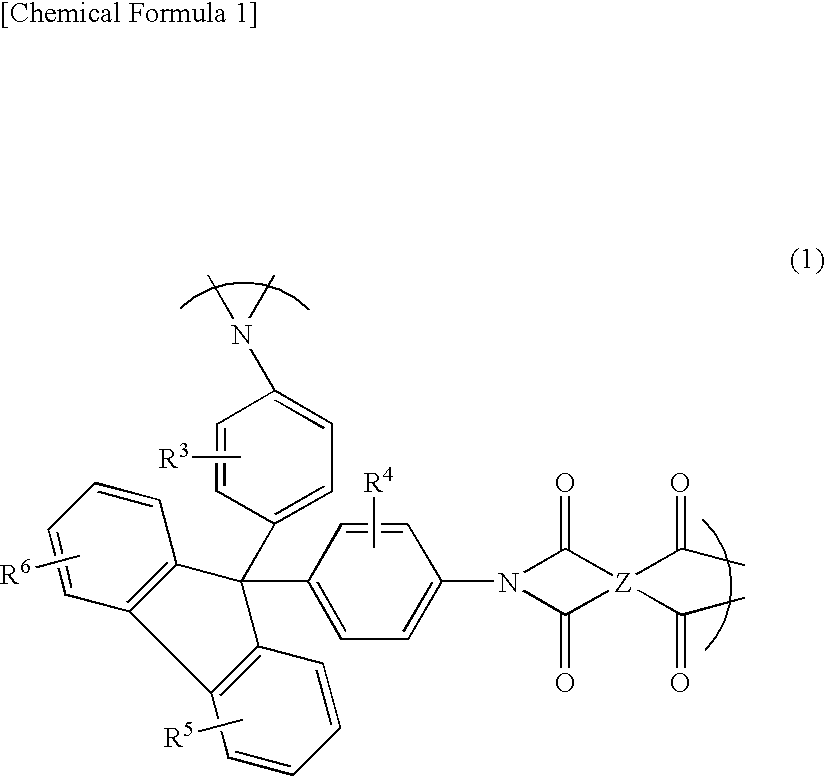

Method for producing birefringent film, optical film and image display device using the same

InactiveUS20060275559A1Good lookingEfficiently obtainedLiquid crystal compositionsLamination ancillary operationsIn planePhase difference

A birefringent film with excellent uniformity in in-plane retardation, retardation in the thickness direction, and alignment axis is provided. The birefringent film is produced in such a manner that, in the step of stretching a polymer film, the polymer film is stretched in a width direction while being shrunk in a longitudinal direction, and assuming that lengths in the width direction and the longitudinal direction of the polymer film before being stretched are 1, a change ratio (STD) of the length in the width direction of the polymer film resulting from the stretching and a change ratio (SMD) of the length in the longitudinal direction of the polymer film resulting from the shrinking satisfy the following formula (1). (1 / STD)1 / 2≦SMD<1 (1)

Owner:NITTO DENKO CORP

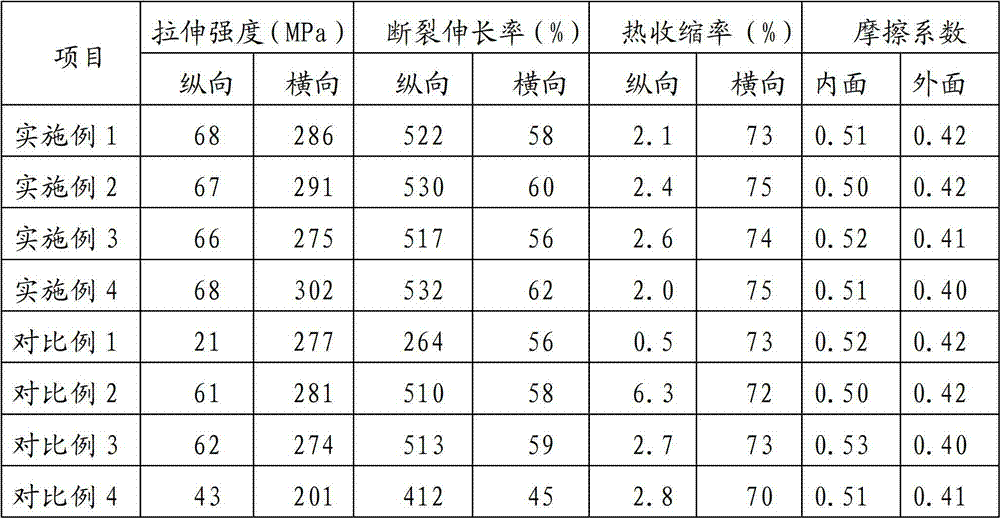

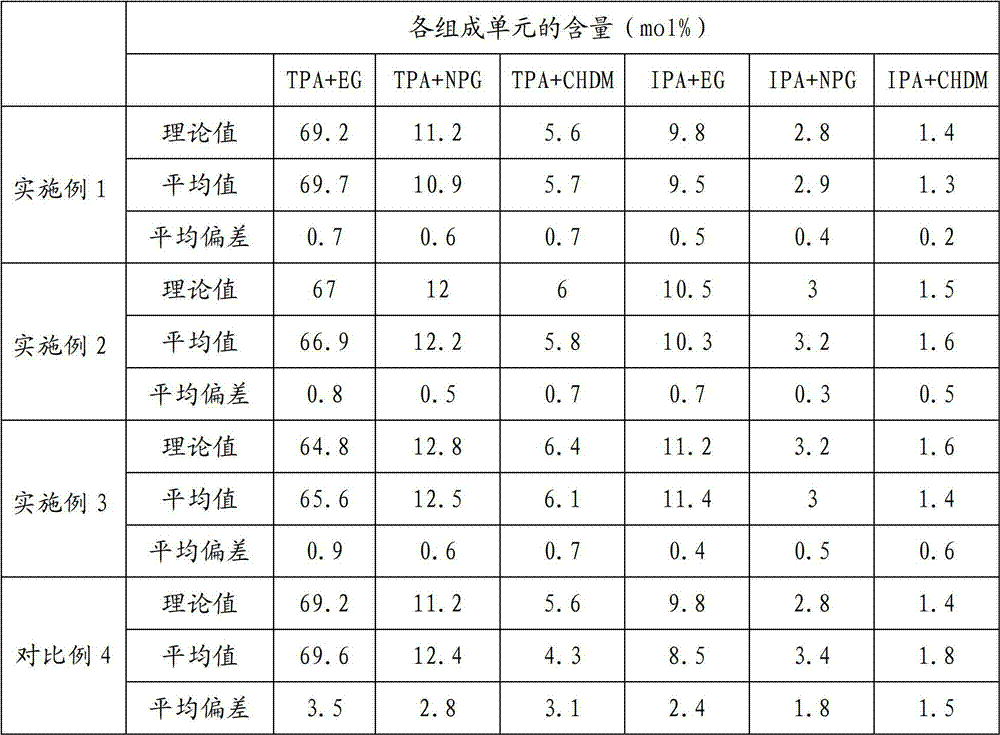

Thermoshrinkable polyester film and preparation method thereof

The invention discloses a thermoshrinkable polyester film and a preparation method thereof. The preparation method comprises steps as follows: various polyester raw materials subjected to dust removal respectively enter storage bins, are respectively metered by an agravic weigher according to the proportion, simultaneously enter an inlet of a double screw extruder, are subjected to melt extrusion by a sandwich layer double screw extruder and two surface layer double screw extruders, and form a casting piece through a three-layer co-extrusion die head; the casting piece is respectively subjected to longitudinal stretching and lateral stretching, wherein the longitudinal stretching comprises a preheating zone, a stretching zone, a thermal setting zone and a cooling zone, and the thermal setting zone of the lateral stretching is more than 15m long; and the casting piece is subjected to traction rolling to obtain the thermoshrinkable polyester film. By adopting the proportioning mode of directly feeding after accurate metering by people, the instantaneous addition error range of various materials is at most 1%; and the material is biaxially stretched, so that the produced film has the advantages of greatly higher density, strength and uniformity, lower longitudinal shrinkage and lateral low-temperature shrinkage, and especially higher ductility and thermoshrinkable uniformity.

Owner:SHANDONG SHENGHE PLASTIC DEV

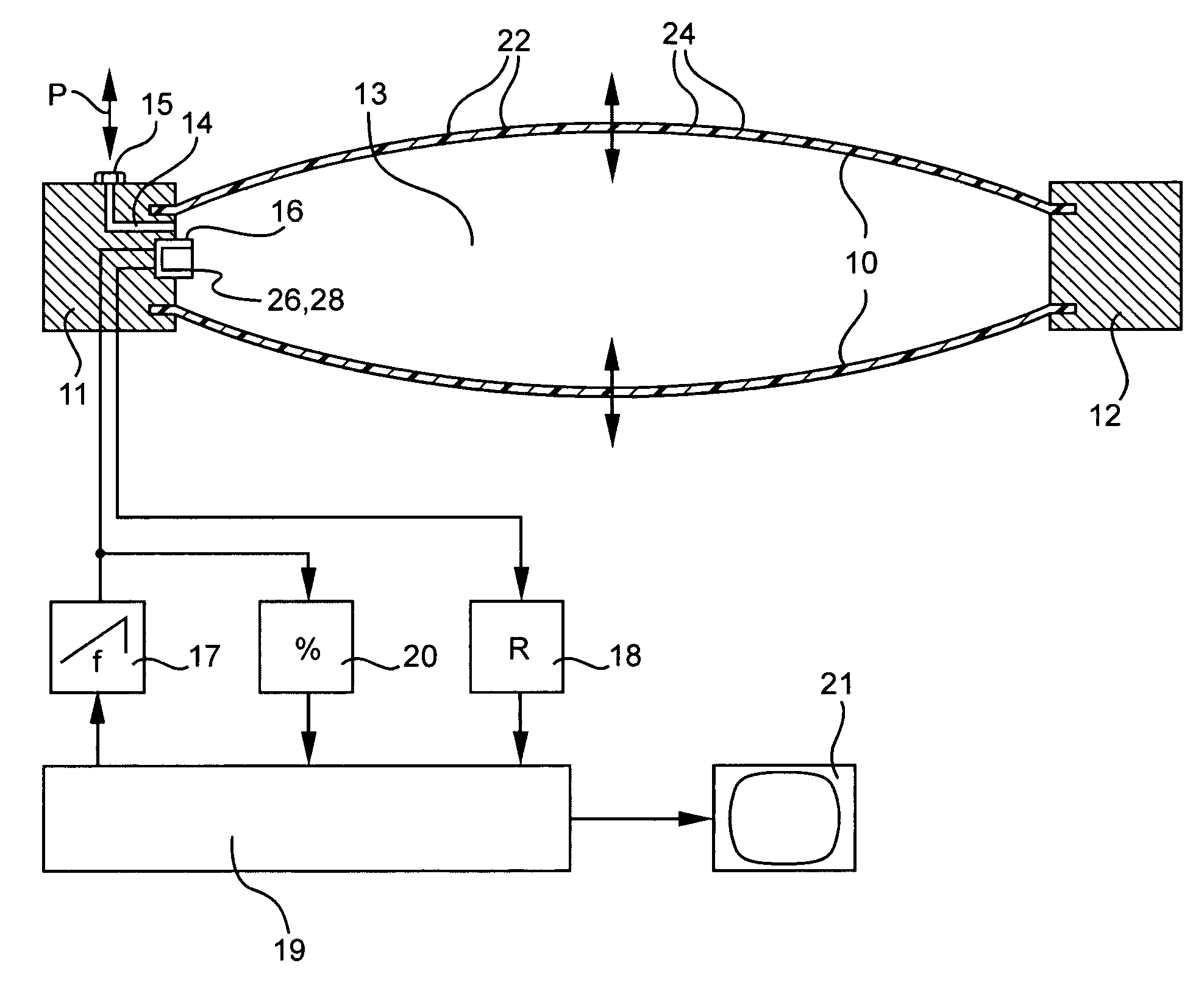

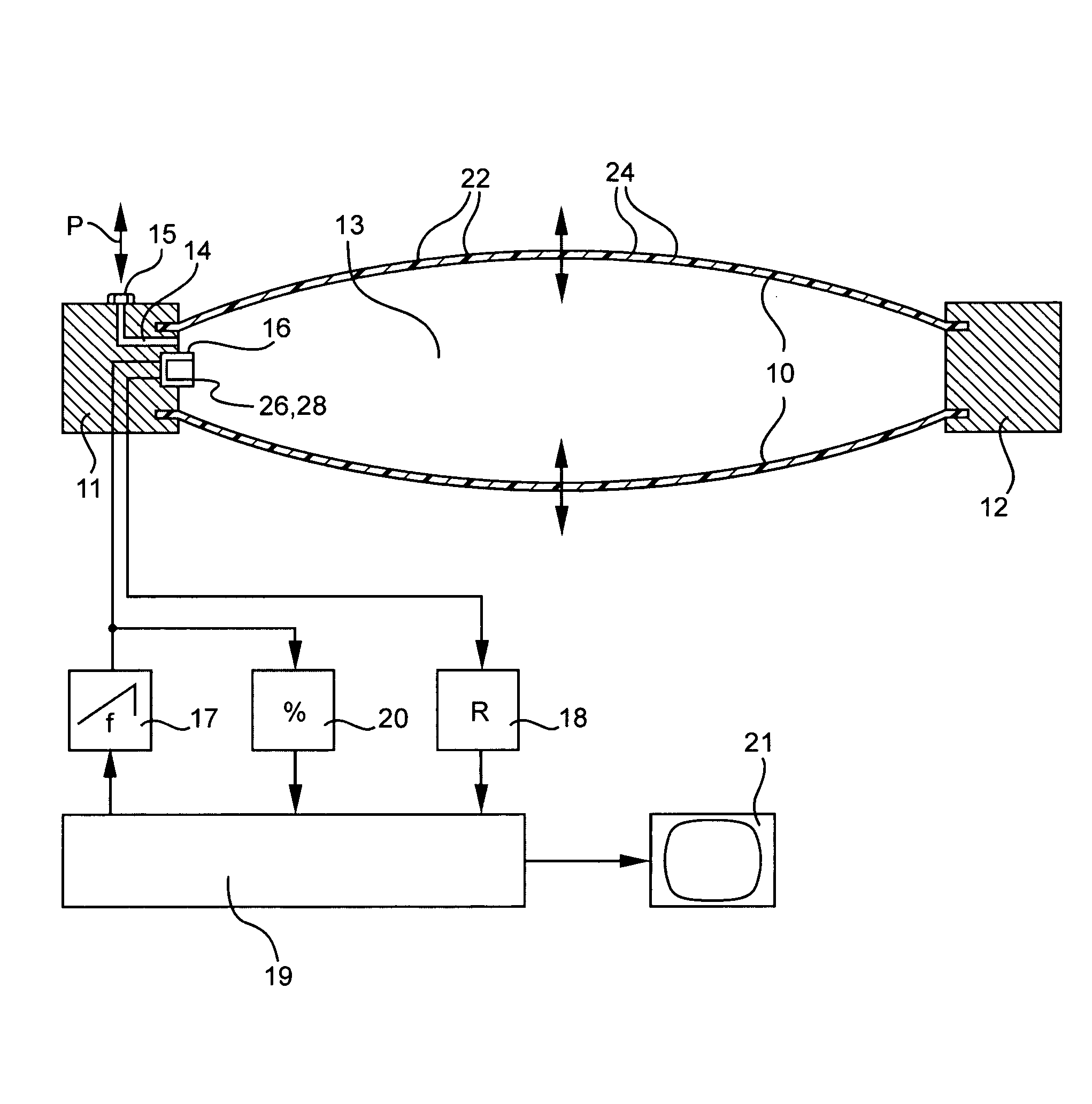

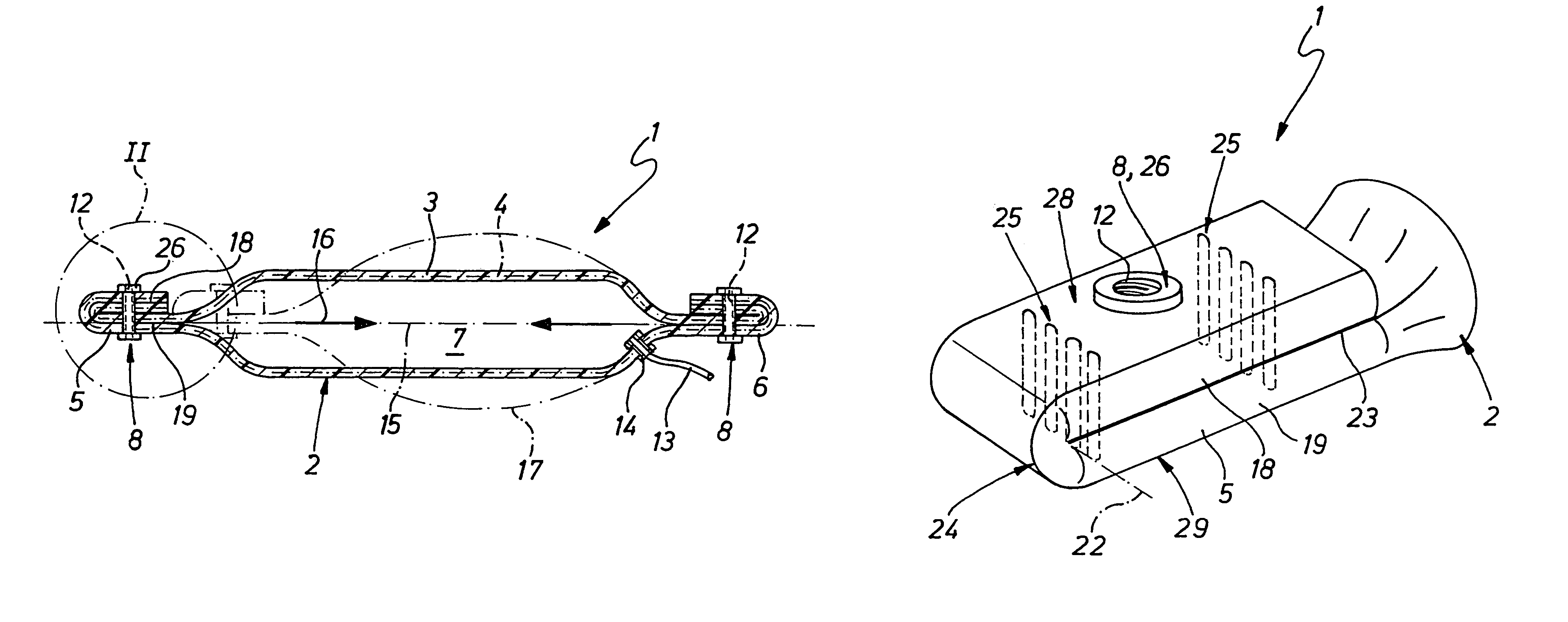

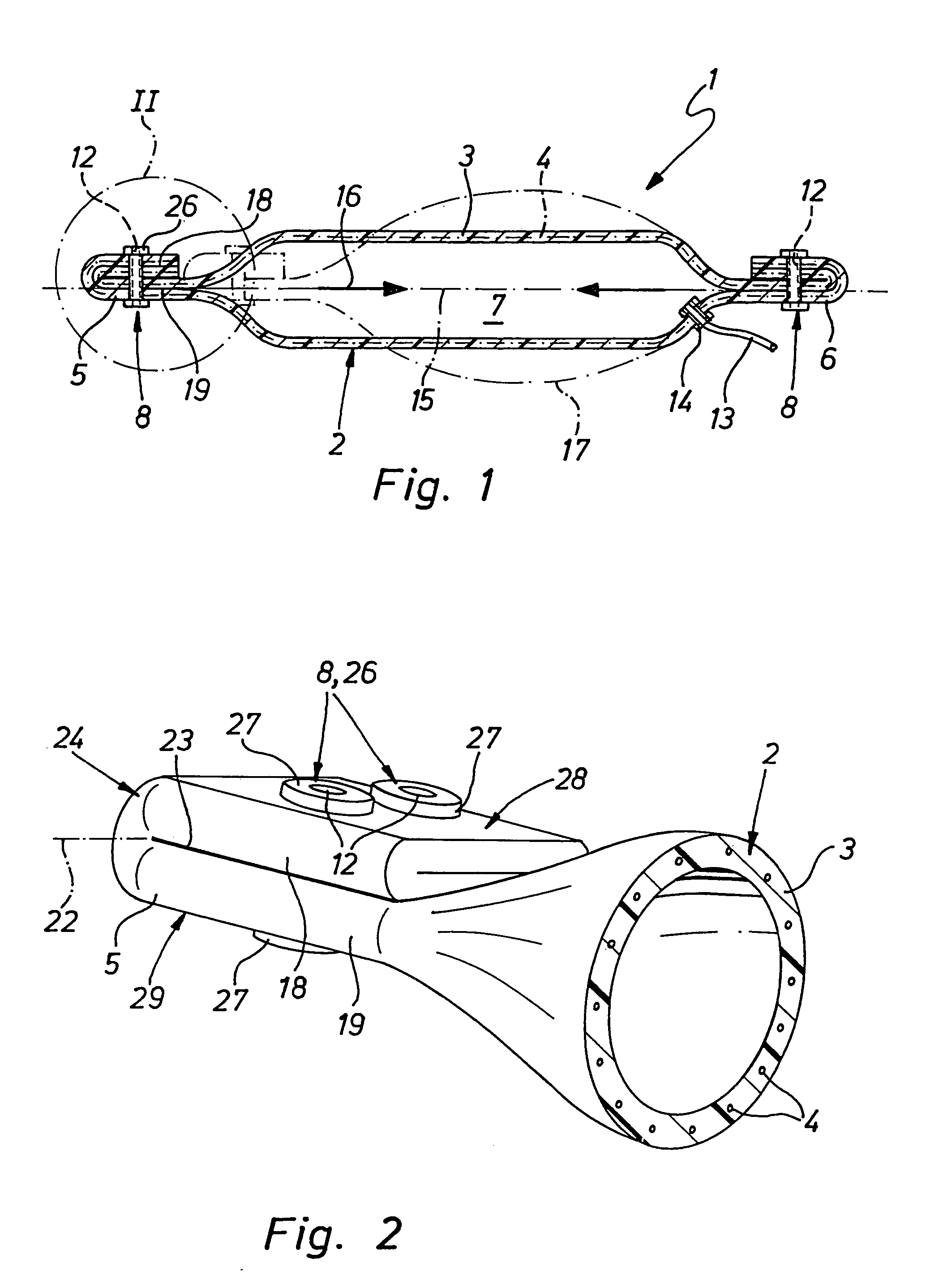

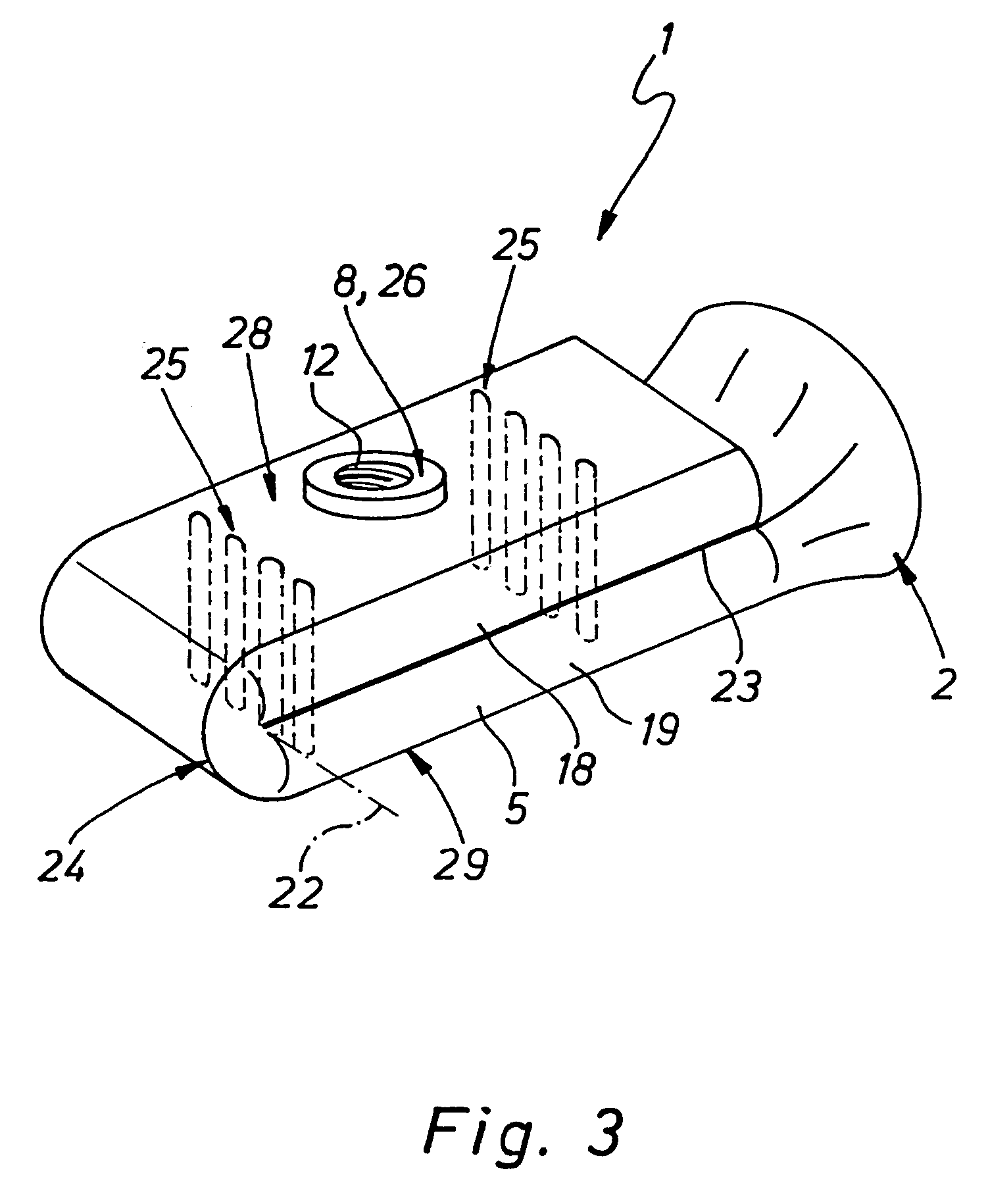

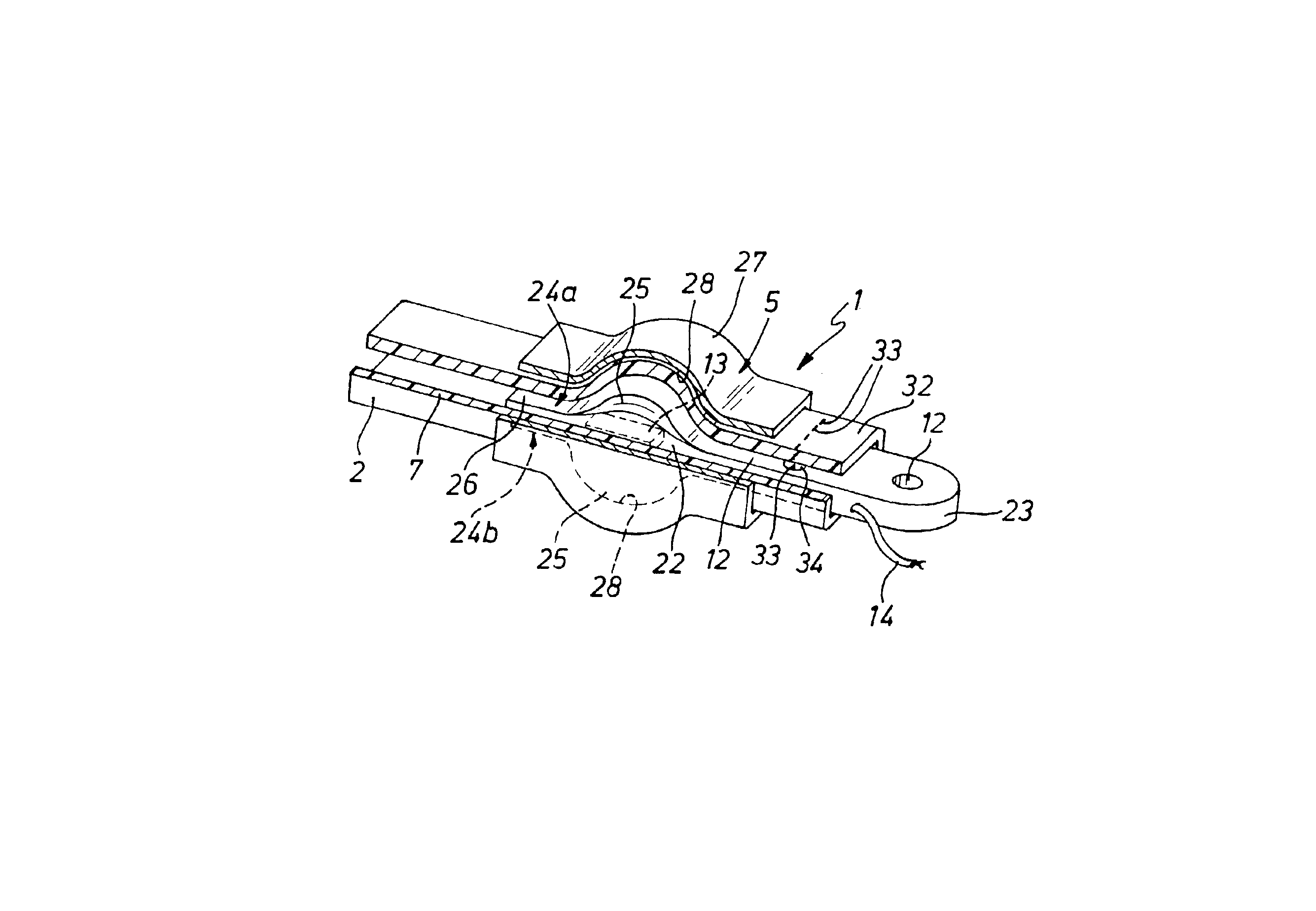

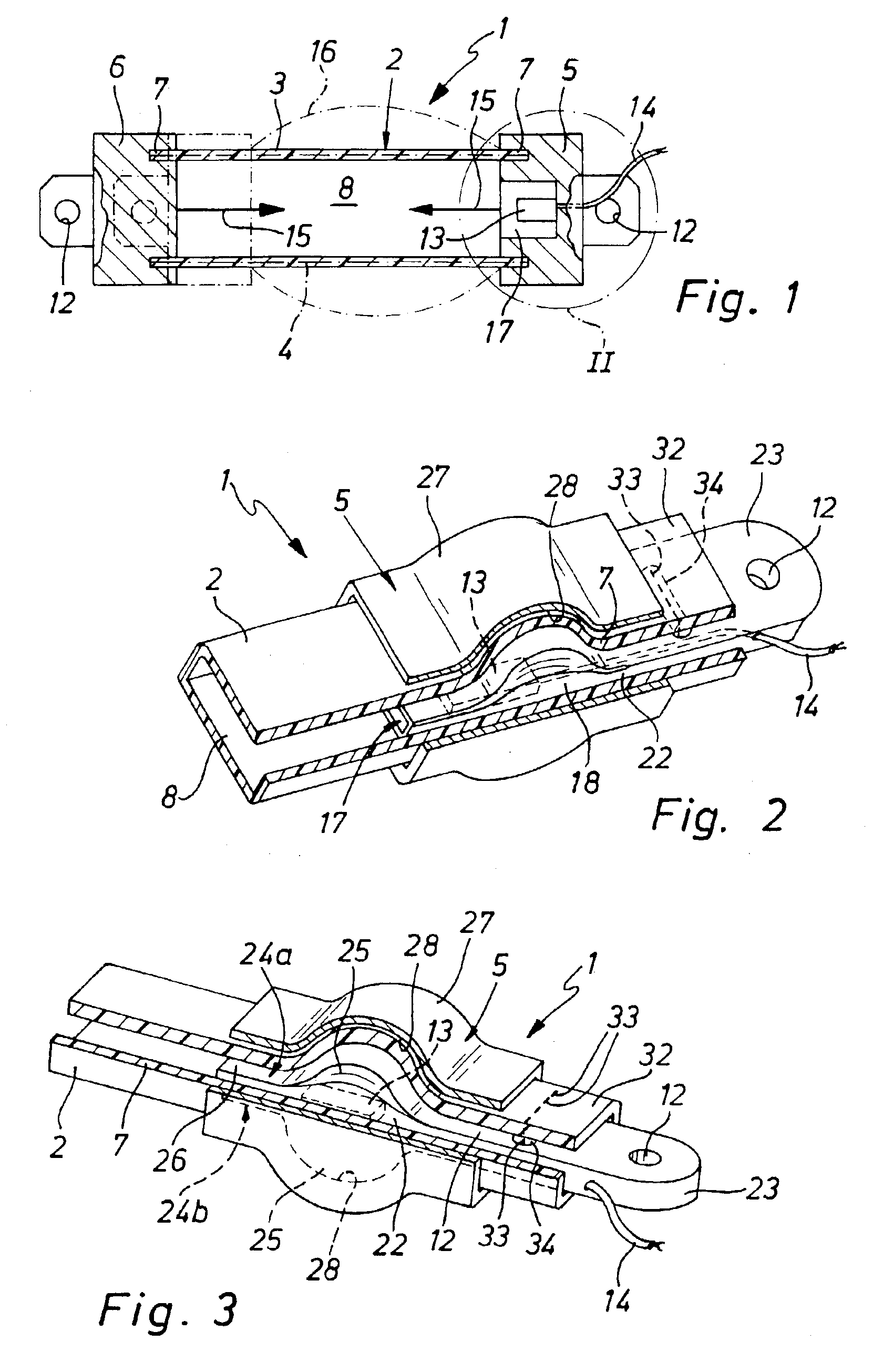

Contractile unit having a position sensor means

InactiveUS7104182B2Satisfactory focussingSatisfactory directionalityReciprocating combination enginesFlexible wall reciprocating enginesInterior spaceInternal pressure

A contractile unit comprising a contractile hose extending between two spaced head pieces and adapted to perform a longitudinal contraction on being subjected to internal pressure, and a position sensor means responsive to the distance between the head pieces. The position sensor means possesses a microwave generator arranged on one of the head pieces and adapted to emit microwaves into the interior space of the contractile unit, an evaluating means being provided responsive to the distance between the head pieces using transit time measurement, phase comparison of the emitted and reflected wave or using determination of the resonant frequency.

Owner:FESTO AG & CO KG

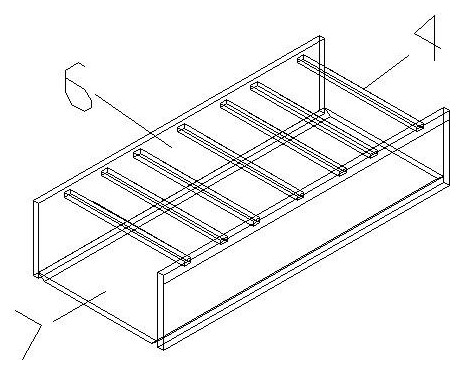

Method for welding heavy-duty trough-type steel

ActiveCN102248263AReduced correction costsPrevent corner deformationArc welding apparatusLongitudinal contractionWaste product

The invention relates to a method for welding heavy-duty trough-type steel. A trough inner support is respectively connected with the inner side of a trough-shaped steel wing plate in a tack welding manner, backing welding is carried out between the trough inner support and the trough-shaped steel wing plate by adopting a carbon dioxide gas arc welding manner which produces minimum welding deformation, and then cosmetic welding is carried out. By adopting the method provided by the invention, torsion deformation caused by longitudinal contraction and transverse contraction of a construction member which can appear in a heavy-duty trough-type steel structure making and welding process can be prevented, and waste products can be avoided. The postwelding flame correction cost is reduced, andthe production efficiency is improved.

Owner:ANHUI WEIHONG STEEL STRUCTURE GRP

Method for producing phase-difference film and method for producing circularly polarizing plate

ActiveUS20160062019A1Improve accuracyExcellent optical propertiesPolarising elementsOptical articlesPhase differenceSheet film

Provided is a method capable of producing a retardation film being excellent in axial accuracy, showing small changes in retardation and dimensions at the time of its heating, and having a slow axis in an oblique direction with high production efficiency. The production method for a retardation film of the present invention includes: holding left and right end portions of a film with left and right variable pitch-type clips configured to have clip pitches changing in a longitudinal direction, respectively; preheating the film; causing the clip pitches of the left and right clips to each independently change to obliquely stretch the film; reducing the clip pitches of the left and right clips to shrink the film in the longitudinal direction; and releasing the film from being held with the clips.

Owner:NITTO DENKO CORP

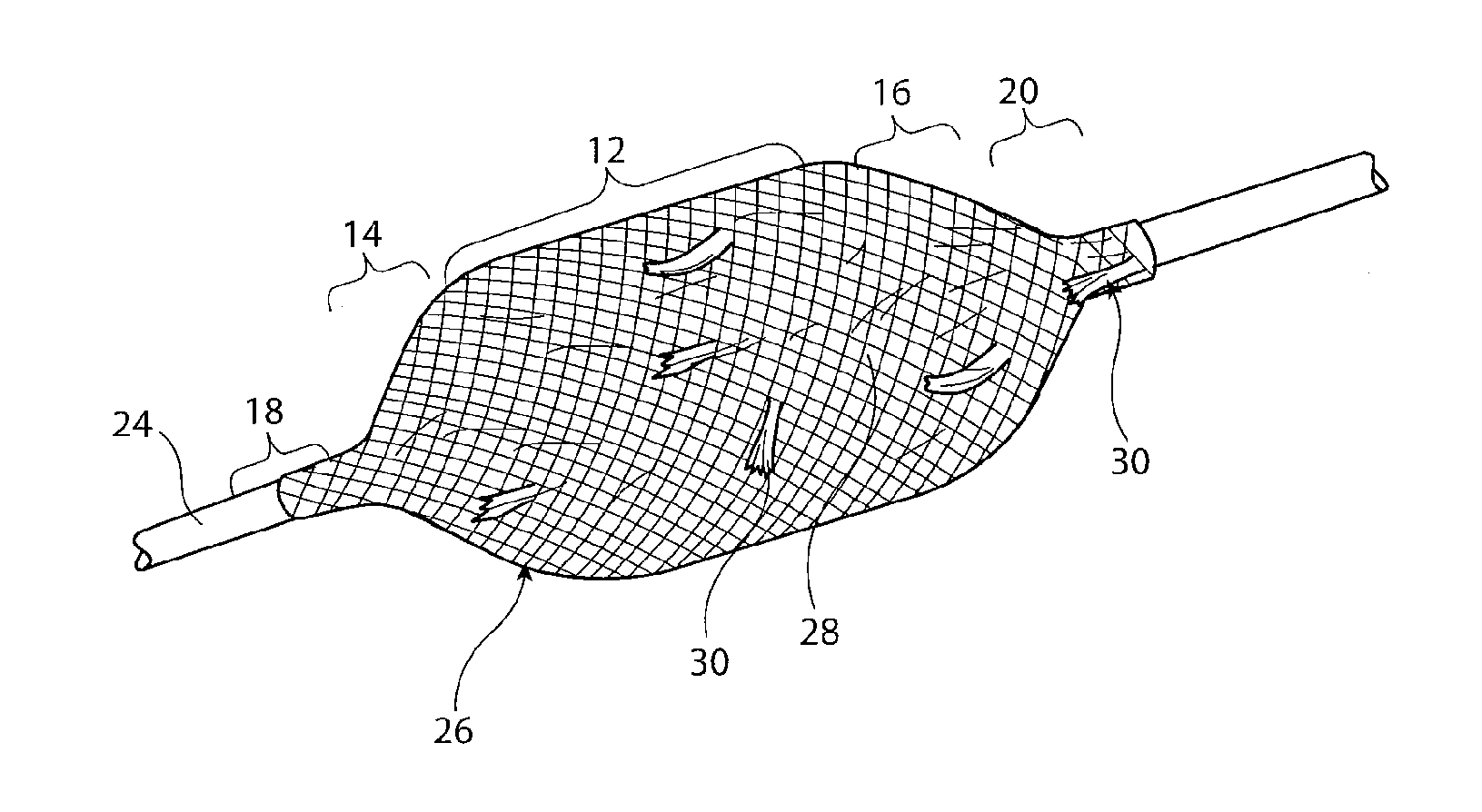

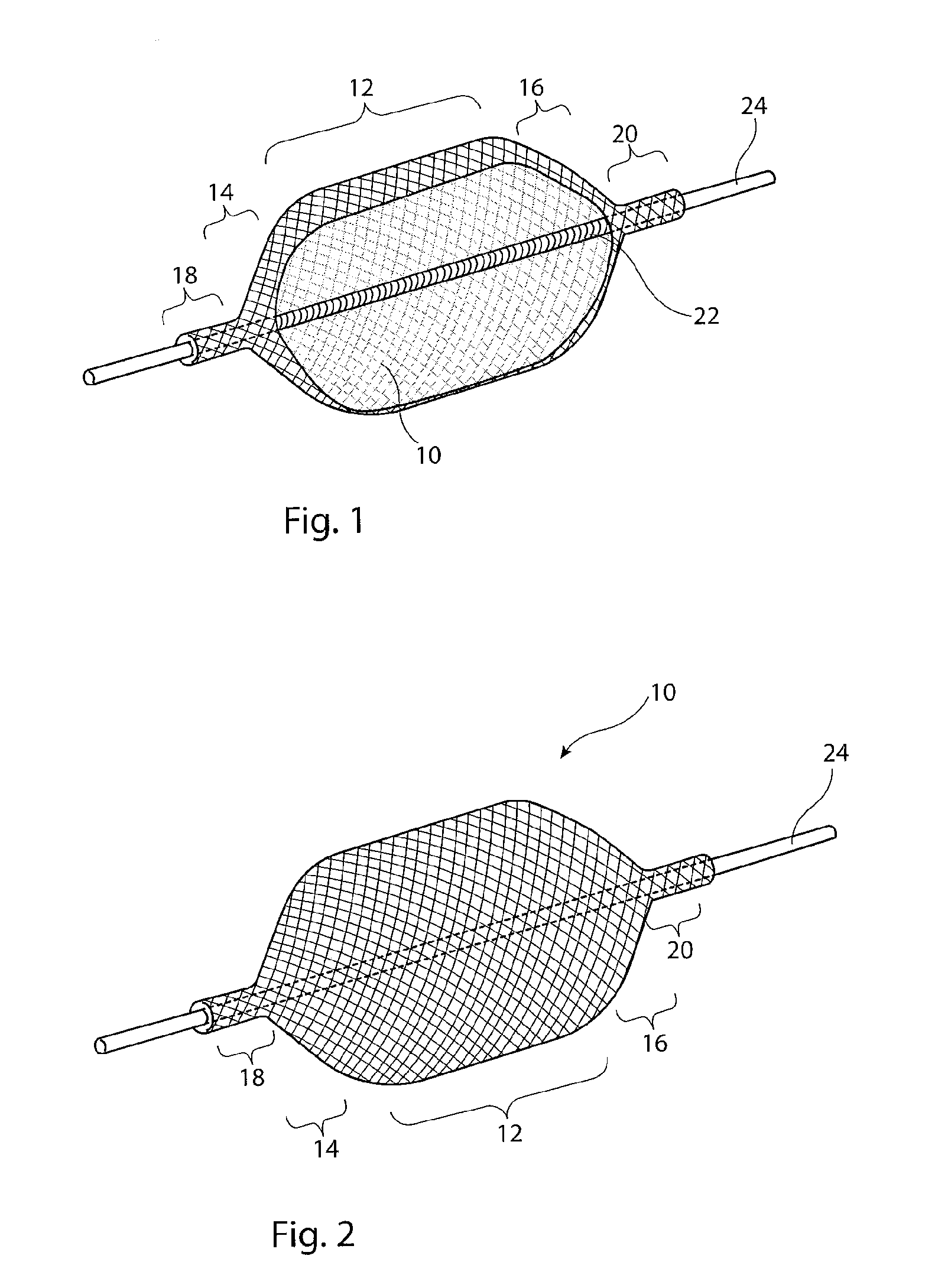

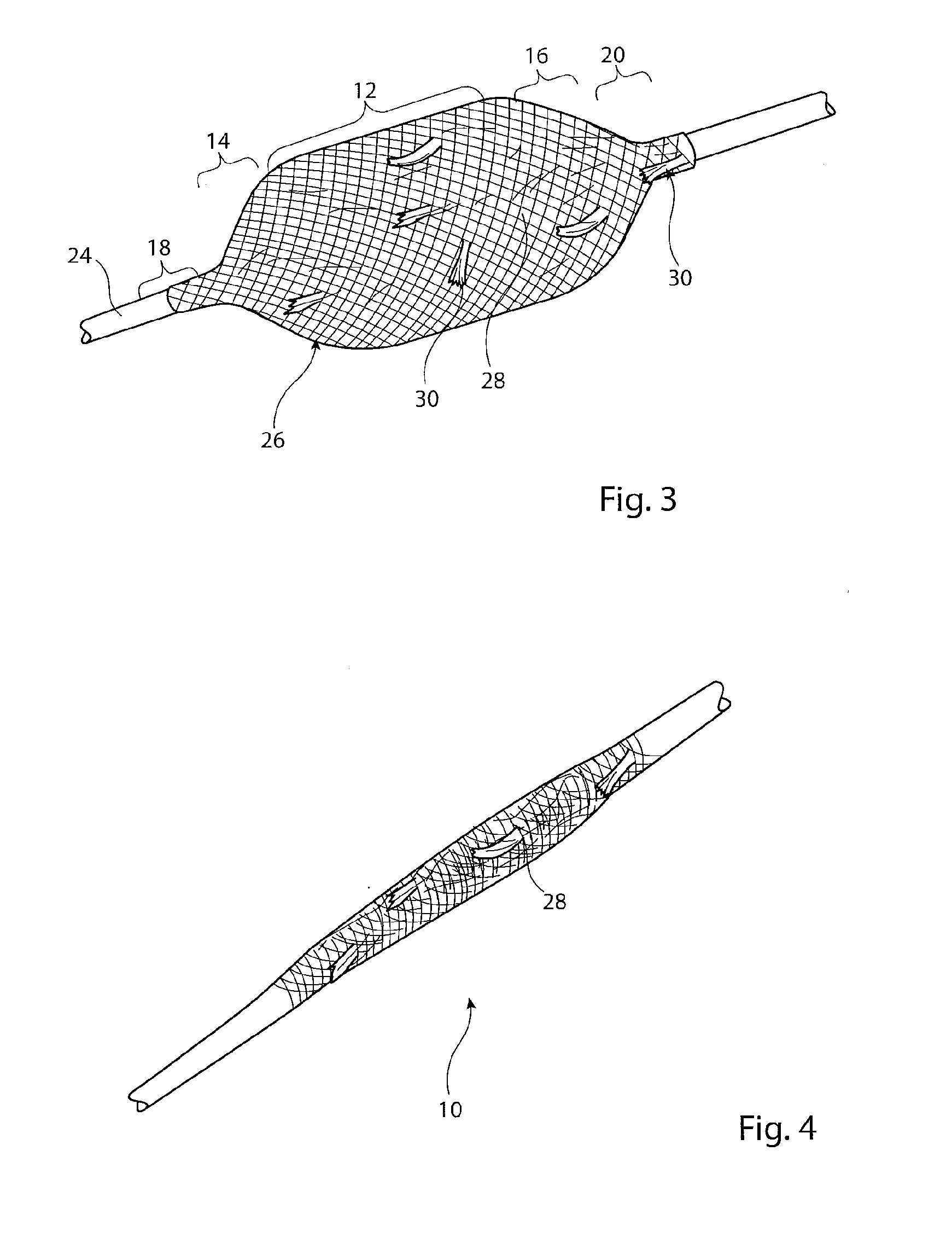

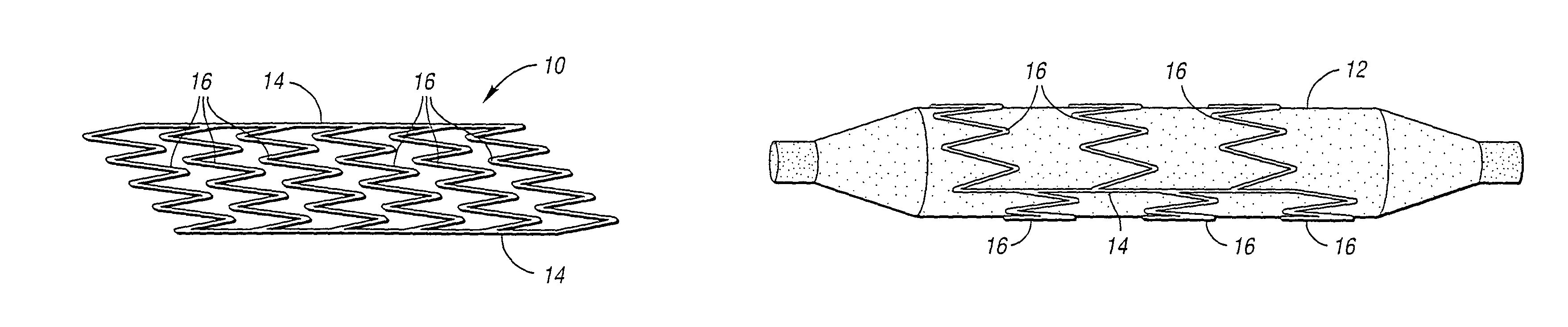

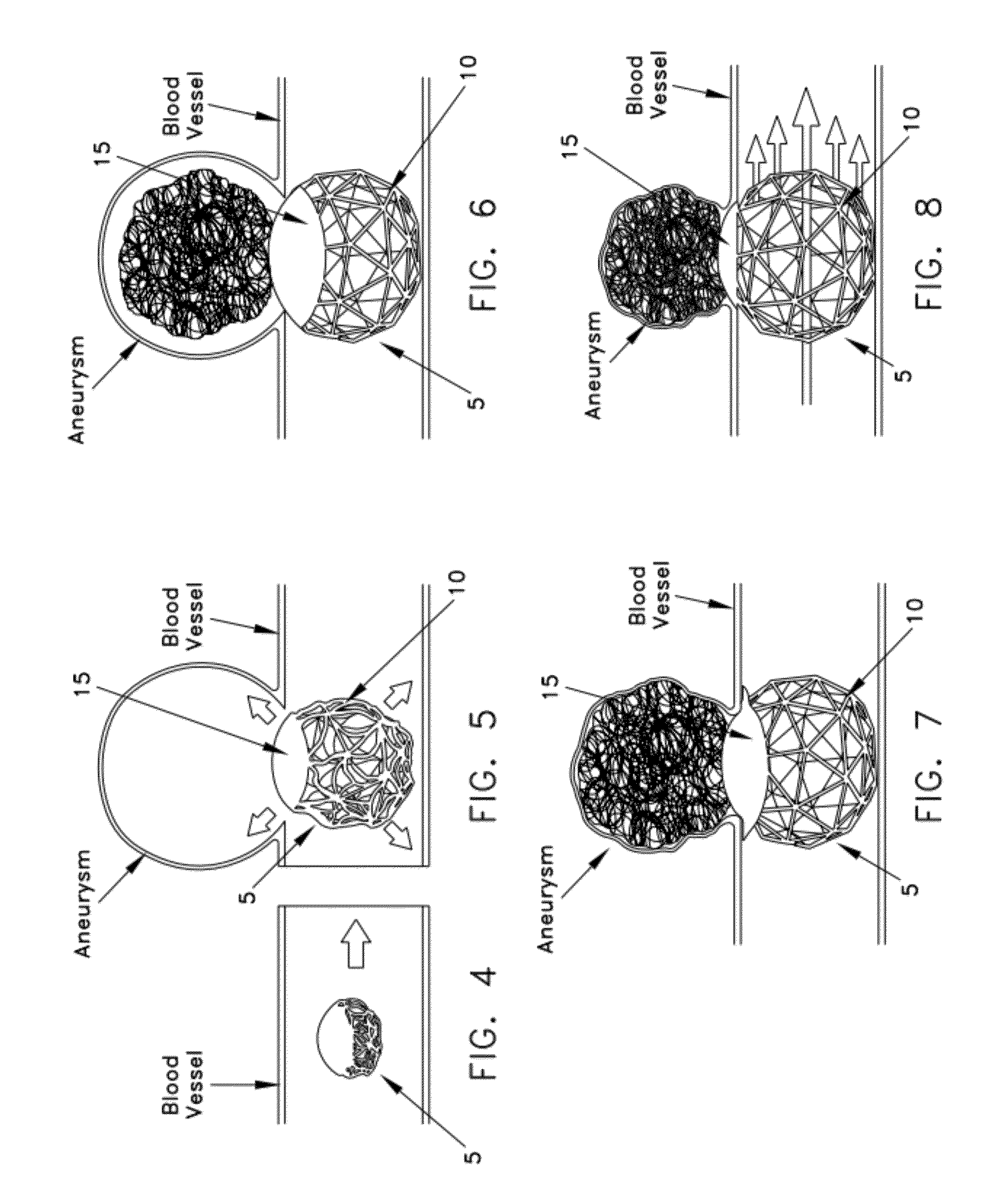

Vascular occlusion device

InactiveUS20130338699A1Reduced structureMinimise volumeDilatorsOcculdersLongitudinal contractionCoil spring

A vascular occluder includes a frame (10) having a generally cylindrical body portion (12), first and second end conical portions (14, 16) and first and second extremities (18, 20). Located within the fame (10) is a fibrous barrier (28) which provides rapid occlusion. The extremities (18, 20) are coupled by a coil spring (22) which acts to pull the extremities (18, 22) towards one another and thereby to cause longitudinal contraction an consequential radial expansion of the frame (10). The coil spring (22) ensures rapid and reliable deployment of the occluder in a patient's vessel. The occluder also can be compressed to a narrow diameter for deployment by means of narrow diameter sheaths.

Owner:COOK MEDICAL TECH LLC

Overfeeding type thin film drawing process

ActiveCN105252752ALongitudinal shrinkage is lowLongitudinal shrinkage stepless adjustmentLongitudinal contractionMechanical engineering

The invention discloses an overfeeding type thin film drawing process. In the thin film drawing process, the length of a thin film clamped by clamps is larger than the length of chain clamps of a drawing machine, redundant parts are formed between the length of the thin film and the length of the chain clamps in the film clamping, feeding and drawing process, and the redundant parts are accumulated in gaps between the clamps to form wrinkles. By the adoption of the overfeeding type thin film drawing process, the thin film is not accumulated in clamping sections of the clamps and only accumulated in the gaps between the front and back clamps, and when the transversely-drawn thin film shrinks longitudinally, the edges of the film do not shrink longitudinally at the clamping portions of the clamps, the portions, close to the inner side, of the thin film shrink longitudinally, and the longitudinal shrinkage ratio is reduced. The redundant parts, namely the wrinkles are reserved in clamping seams and cut off at the rear edge portion of a transversely-drawing outlet and are not components of products. By the adoption of the overfeeding type thin film drawing process, the stepless adjustment longitudinal shrinkage ratio can be acquired, so that the longitudinal shrinkage ratio of the transversely-drawn thin film is controlled within a controllable range.

Owner:北京华腾佳和科技有限公司 +1

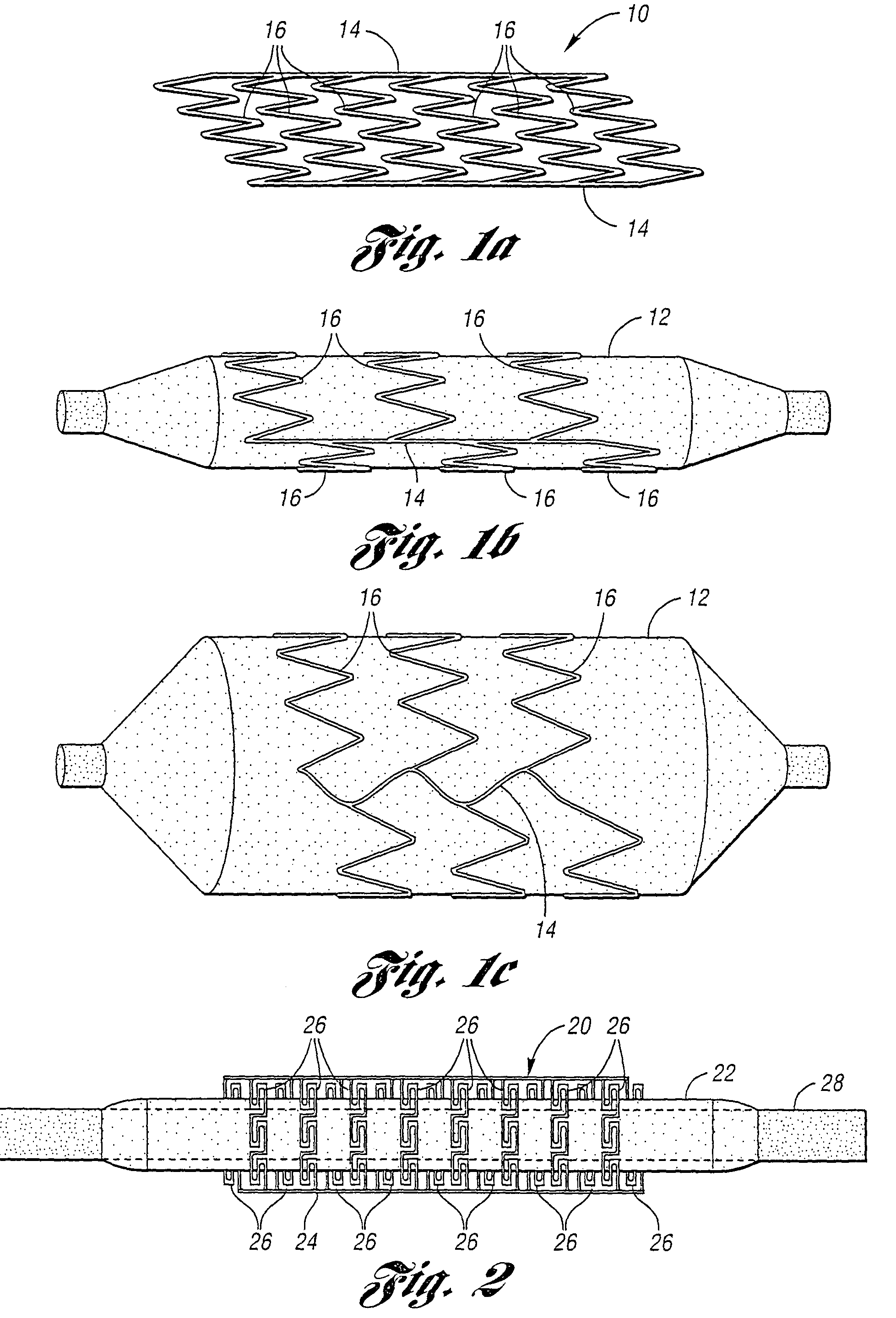

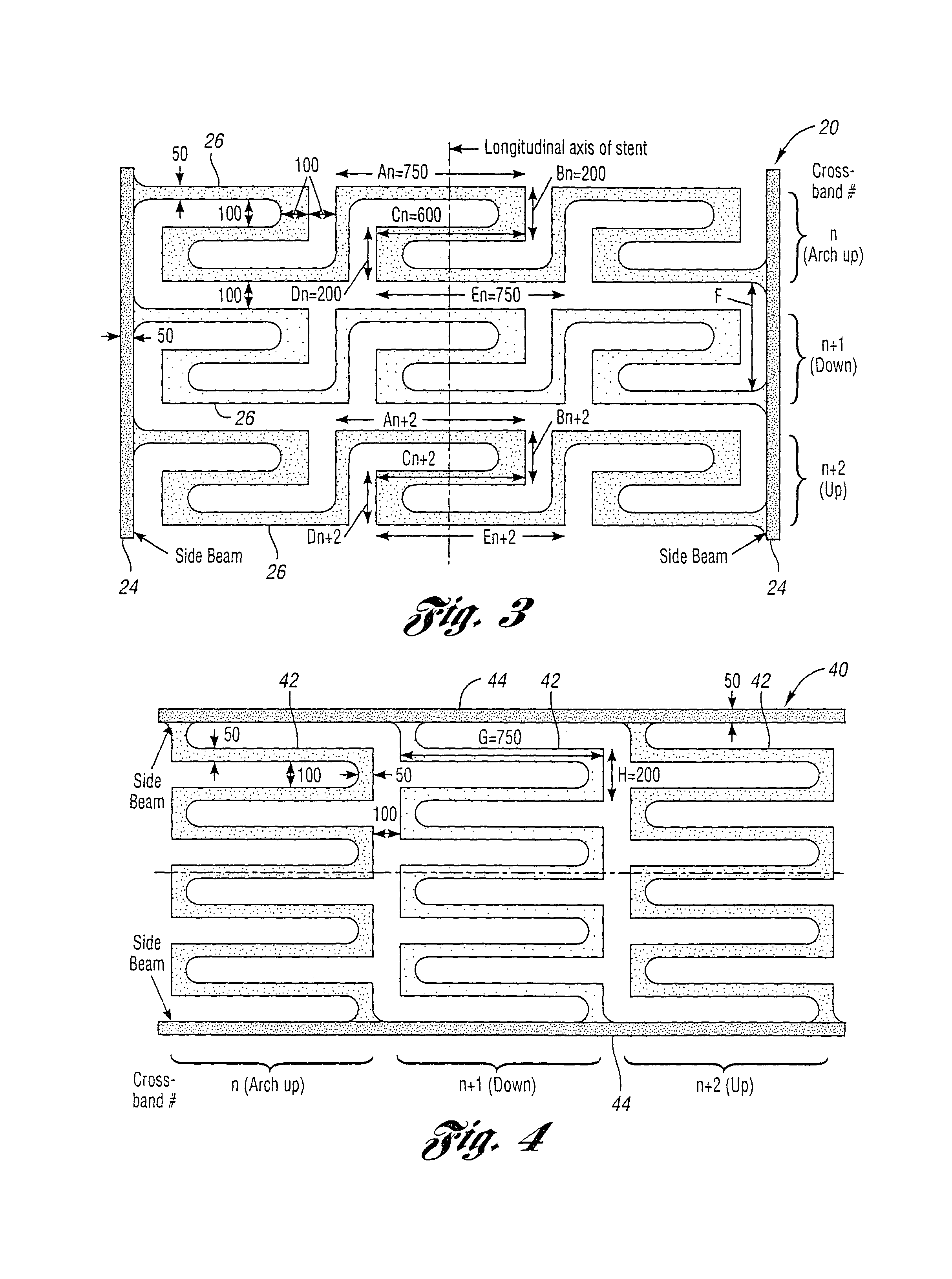

Assembly and planar structure for use therein which is expandable into a 3-D structure such as a stent and device for making the planar structure

ActiveUS9440302B2Easy to manufactureStentsRestraining devicesAngioplasty balloonManufacturing technology

An assembly and planar structure for use therein which is expandable into a 3-D structure such as a stent and device for making the planar structure are provided. The planar structure permits the use of planar batch manufacturing technologies to fabricate coronary artery stents. Stents with different wall patterns are fabricated from 50 μm thick stainless steel foil using micro-electro-discharge machining, and expanded to tubular shapes by using angioplasty balloons. The stents are free-standing. The free-standing stents exhibit diameter variations of <±4%, almost zero radial recoil after deflation of the balloon, and longitudinal shrinkage of <3% upon expansion. A variation of the stents uses breakable links to provide additional customization of electrical and mechanical properties. Loading tests reveal that the radial strengths match commercially available stents, while longitudinal compliance, at 0.02 m / N for a 4 mm long section of the stent, is substantially higher.

Owner:RGT UNIV OF MICHIGAN

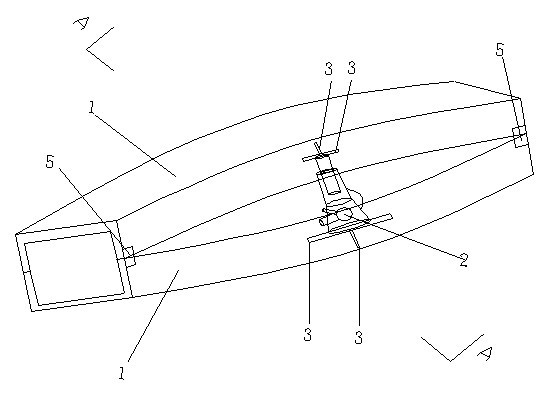

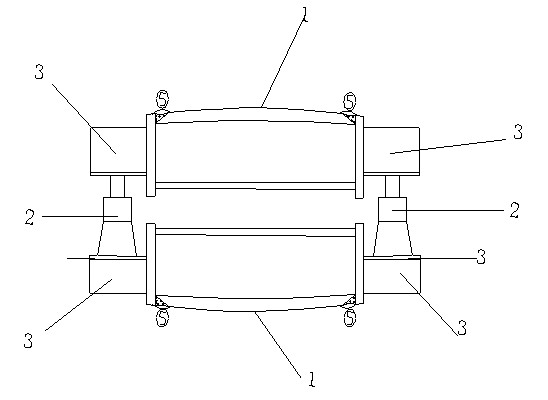

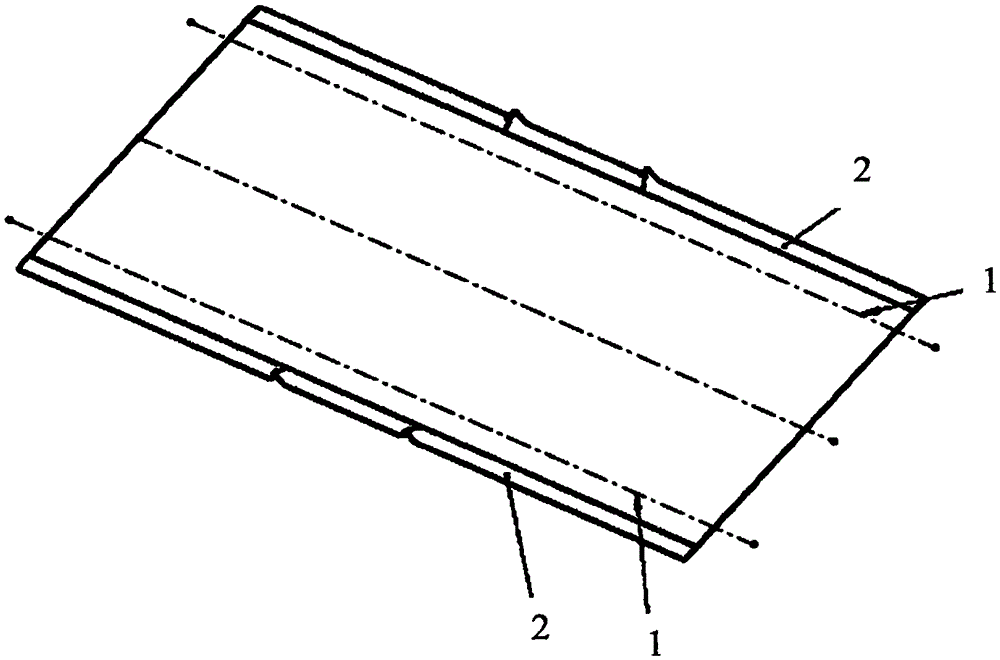

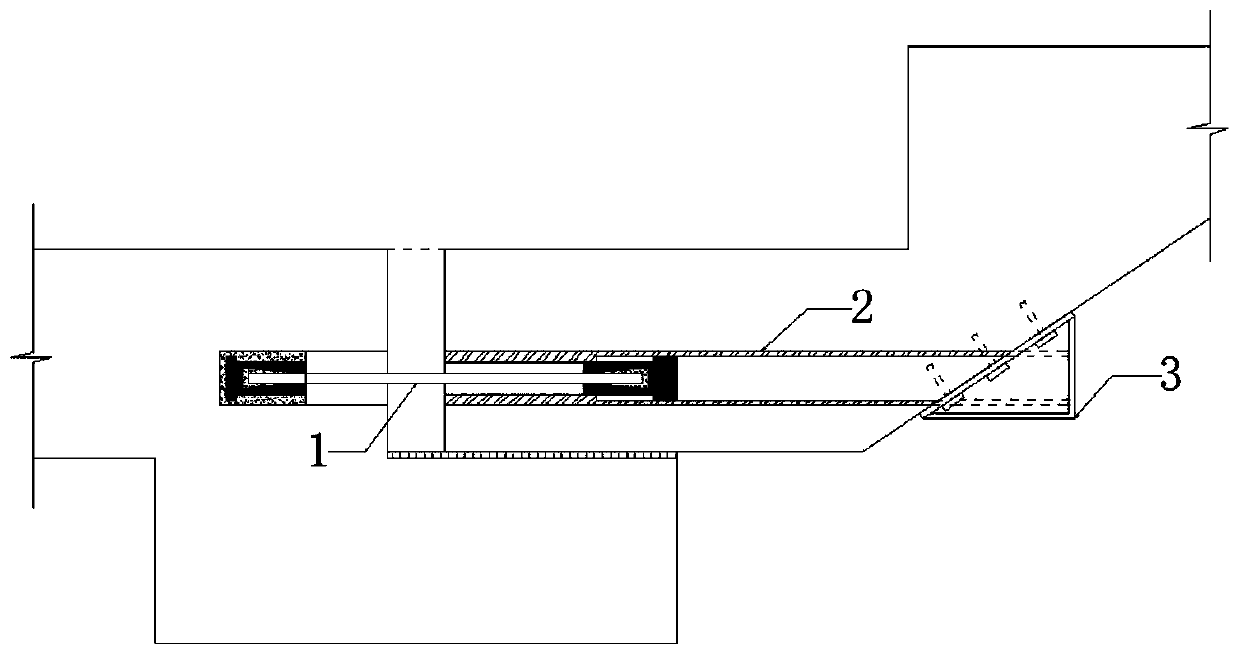

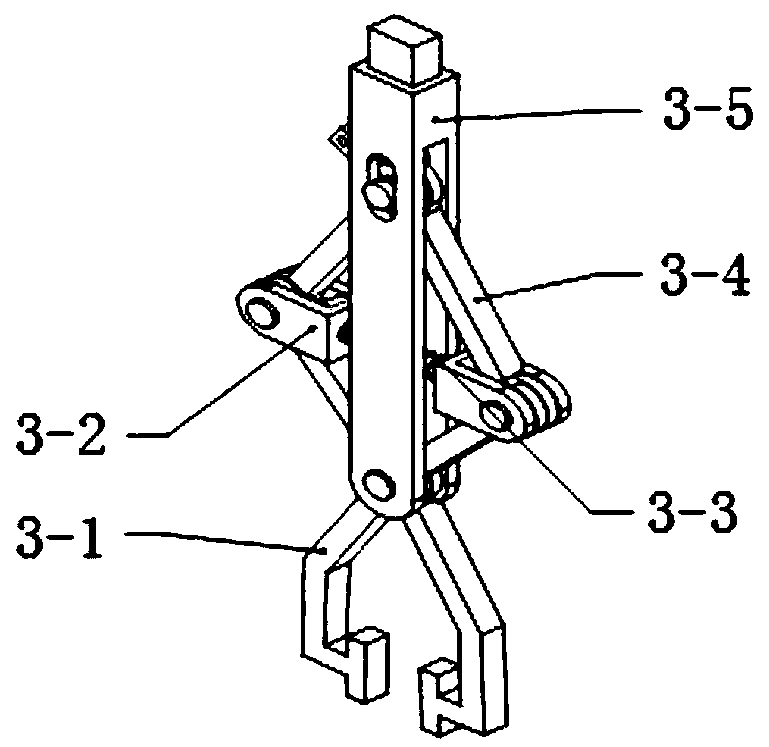

Limiting device for prefabricated stair sliding support

PendingCN110748102AAvoid destructionPrevent disengagementProtective buildings/sheltersStairway-like structuresLongitudinal contractionClassical mechanics

The invention discloses a limiting device for a prefabricated stair sliding support, and is used for limiting the relative sliding movement between a prefabricated concrete stair and a stair beam. Thelimiting device comprises a pull linkage rod (1) and an embedded steel pipe (2), wherein the embedded steel pipe (2) is pre-embedded in the lower part of a stair section platform of the prefabricatedconcrete stair, one end of the pull linkage rod (1) is anchored in the stair beam, the other end of the pull linkage rod (1) is sleeved in the embedded steel pipe (2), and the inner wall of the embedded steel pipe (2) is provided with a contraction-limiting mechanism (21) for limiting the longitudinal contraction of the pull linkage rod (1). According to the limiting device for the prefabricatedstair sliding support, the component stress design is consistent with the deformation direction, the stress is reasonable, and the strength is high; main components are internally arranged, so that appearance of a building is not affected, the durability is good, and the space occupation is small; and the device is easy to construct and install, and the construction connection is reliable.

Owner:YANGZHOU UNIV

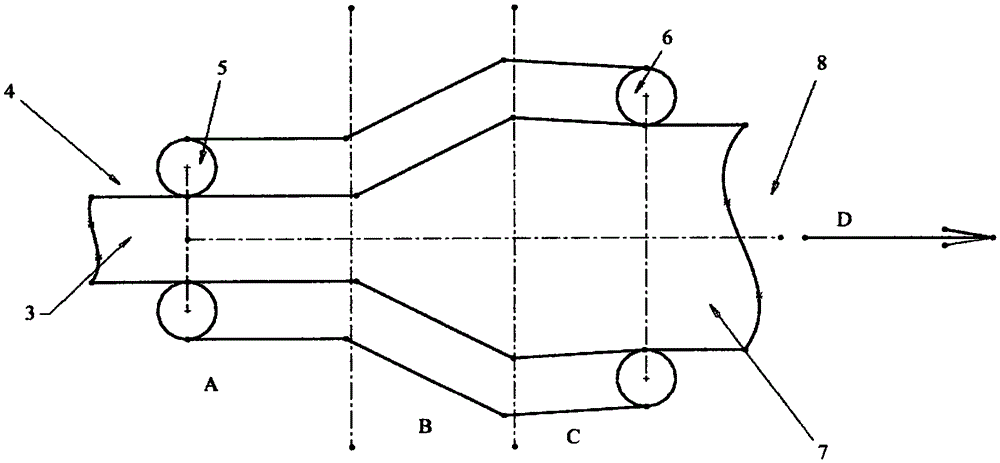

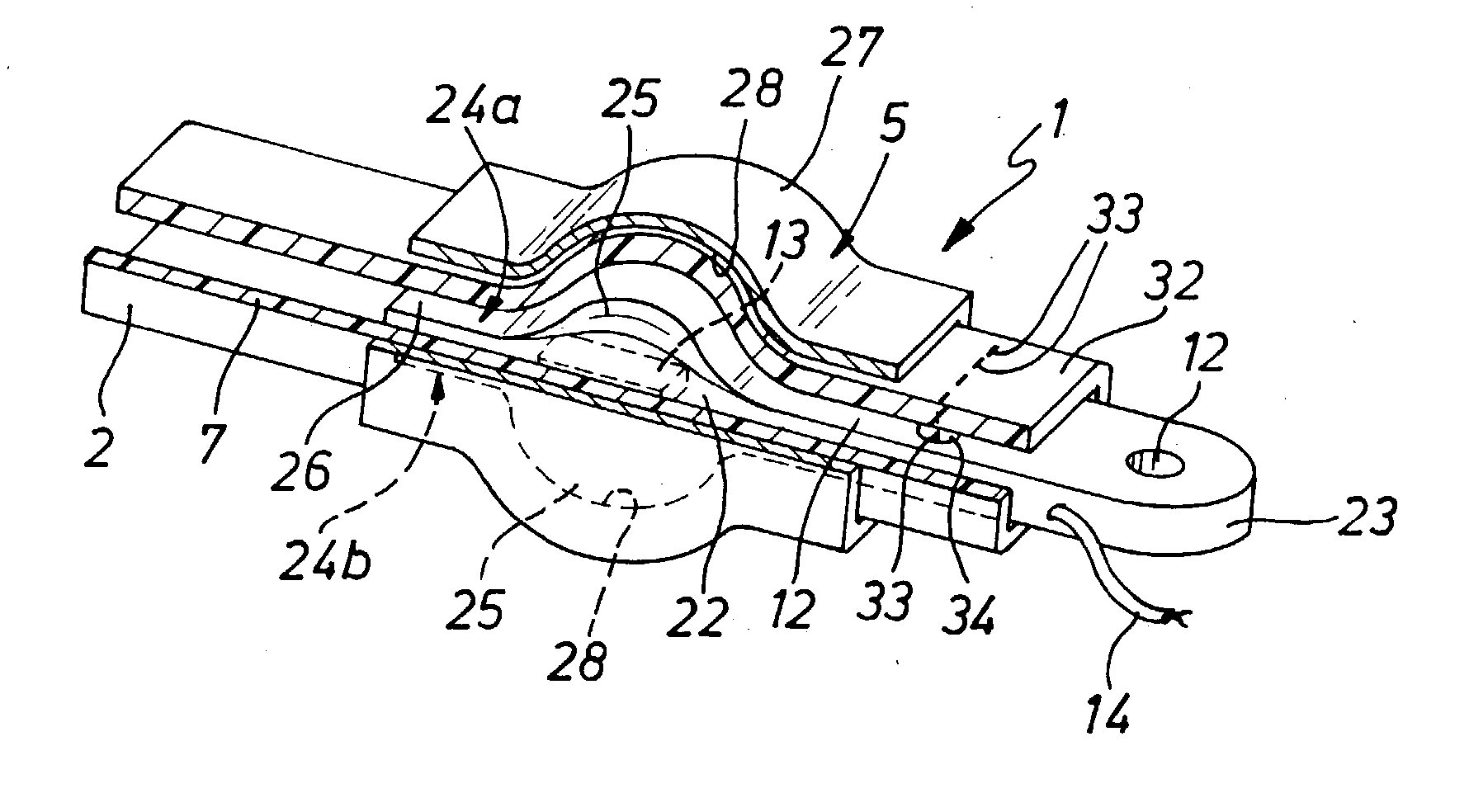

Fluid-actuated contraction drive and associated contraction tube

InactiveUS7185580B2Simply and reliably sealedImprove sealingFlexible wall reciprocating enginesFluid-pressure actuatorsLongitudinal contractionEngineering

A fluid power contractile drive comprising a contractile hose (2), which on fluid actuation of an actuation space (7) delimited by it undergoes longitudinal contraction and which at its two terminal regions (5 and 6) is adapted to be, or is, provided with a force output means (8) rendering possible output of the drive force produced. At one terminal region (5 and 6) at least the contractile hose (2) possesses a flat configuration and is bent over, the hose sections (18 and 19) of the hose sections being placed adjacent to each other owing to such bending over being connected firmly with each other.

Owner:FESTO AG & CO KG

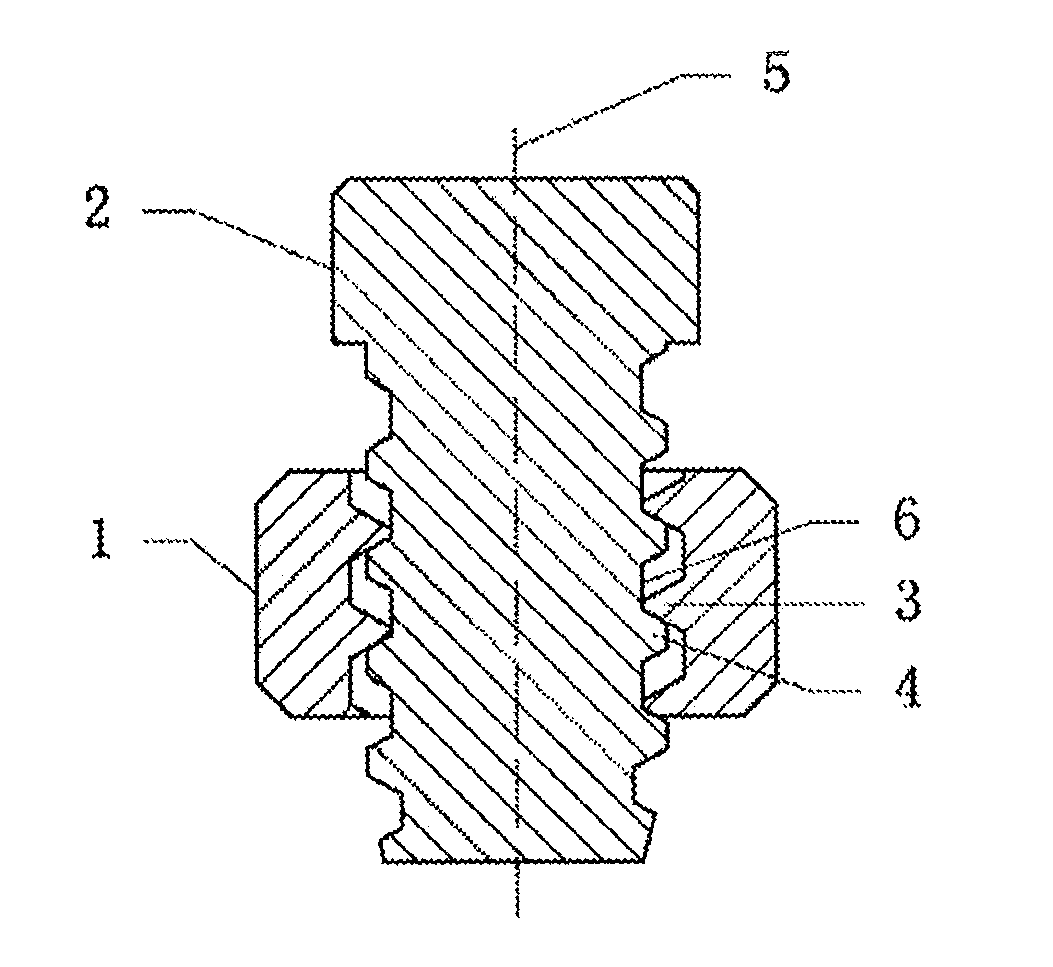

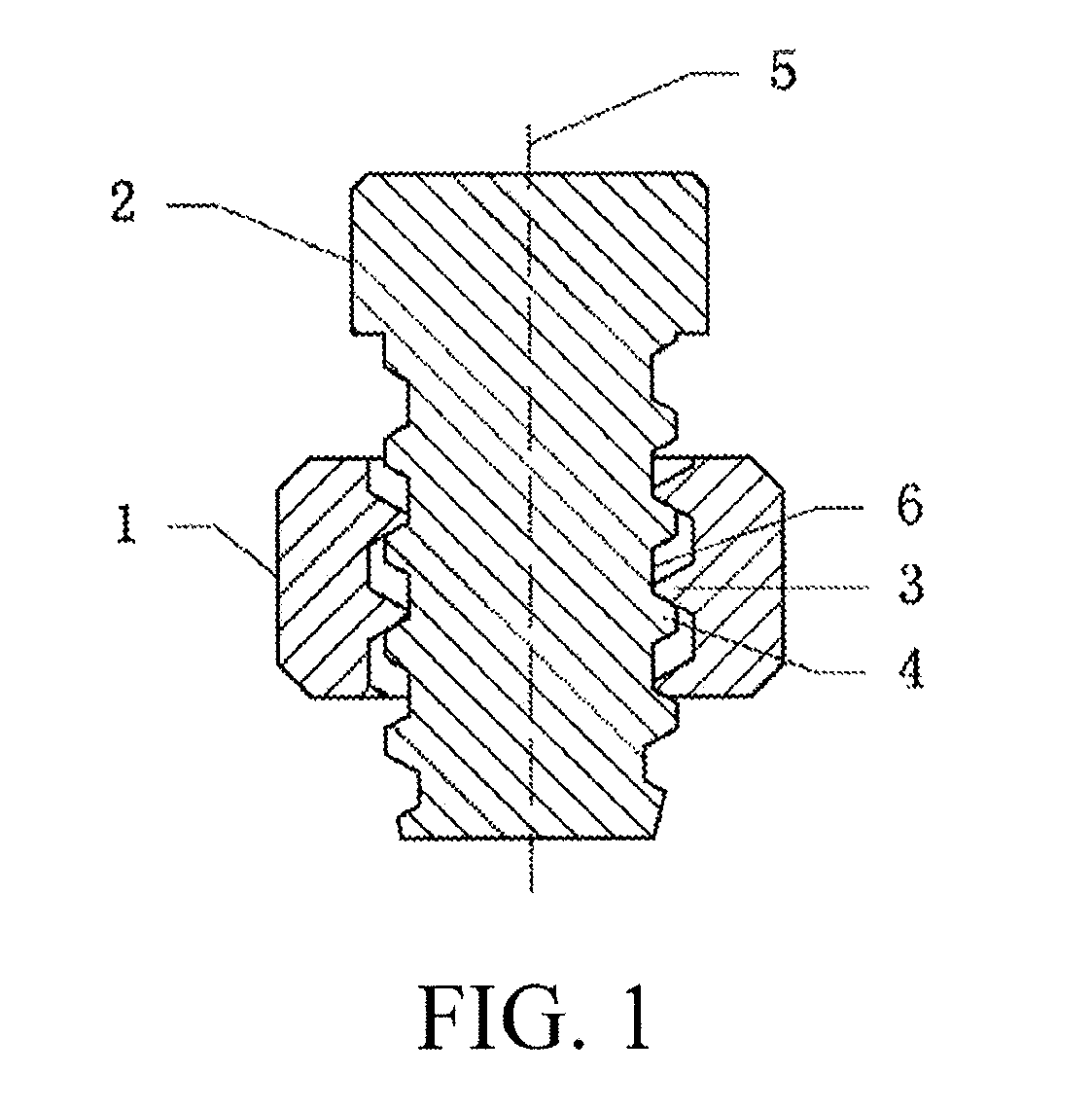

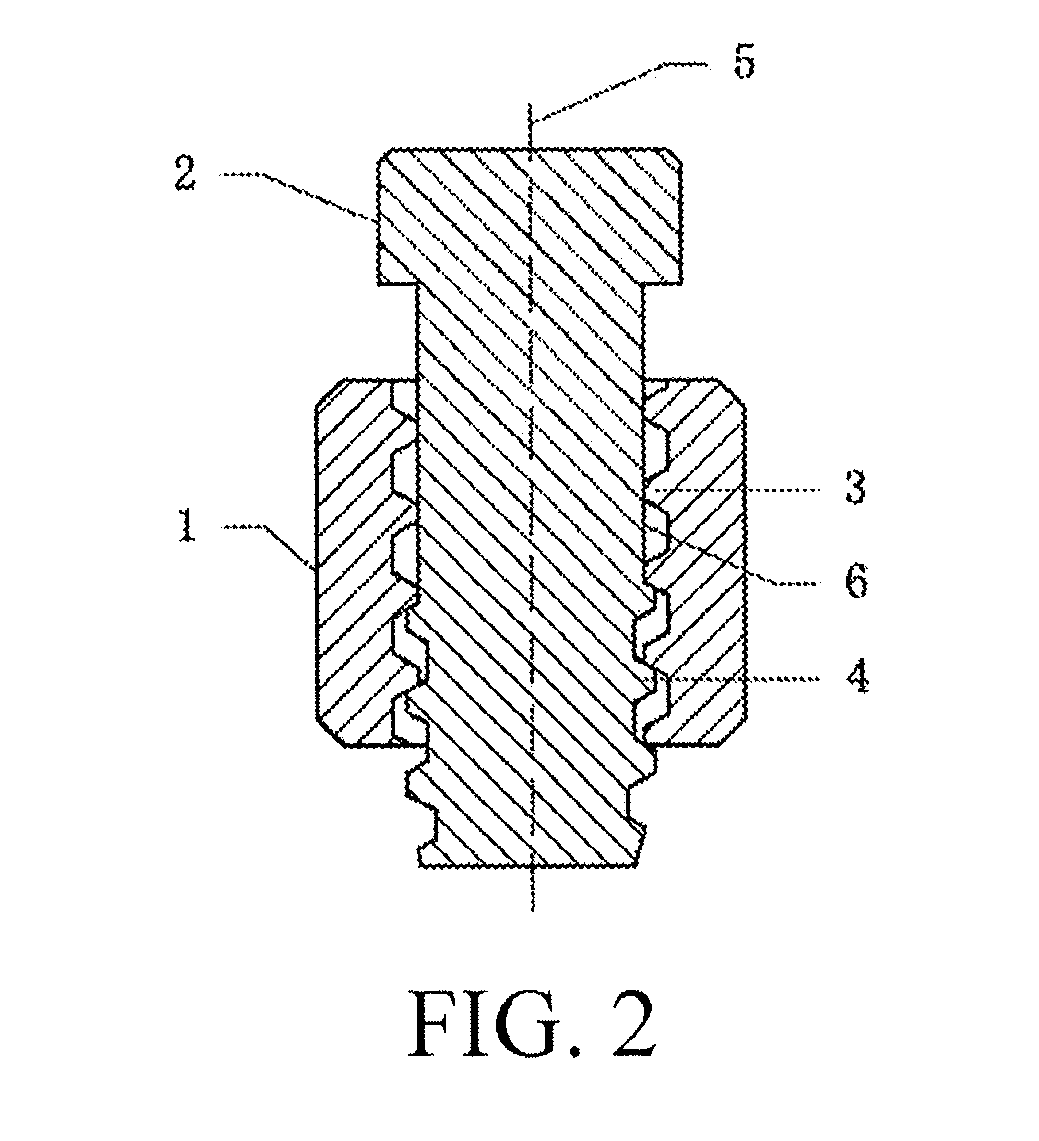

Anti-loosening cylindrical threaded part

InactiveUS20160131176A1Effective preventionStabler loosening preventionNutsBoltsLongitudinal contractionEngineering

An anti-loosening cylindrical threaded part has internal and external threaded parts. A cylindrical internal thread is arranged in an internal threaded part inner hole, a cylindrical external thread is arranged on an external threaded part screw having a cylindrical surface parallel to an external thread longitudinal center axis, and a cylindrical surface external diameter is less than an external thread maximum external diameter. Surfaces of the threads and the cylindrical surface are not covered with anti-loosening materials. After the threads are mutually screwed, the cylindrical surface and an internal thread crest are mutually close contact structures, that is, a horizontal locking structure. Loosening can be effectively prevented between the cylindrical internal and external threaded parts without longitudinal contractility of the threaded part and a workpiece, and the structure is suitable for loosening prevention in various connections of the cylindrical threaded parts, and the loosening prevention is stabler.

Owner:XU SONGLIN

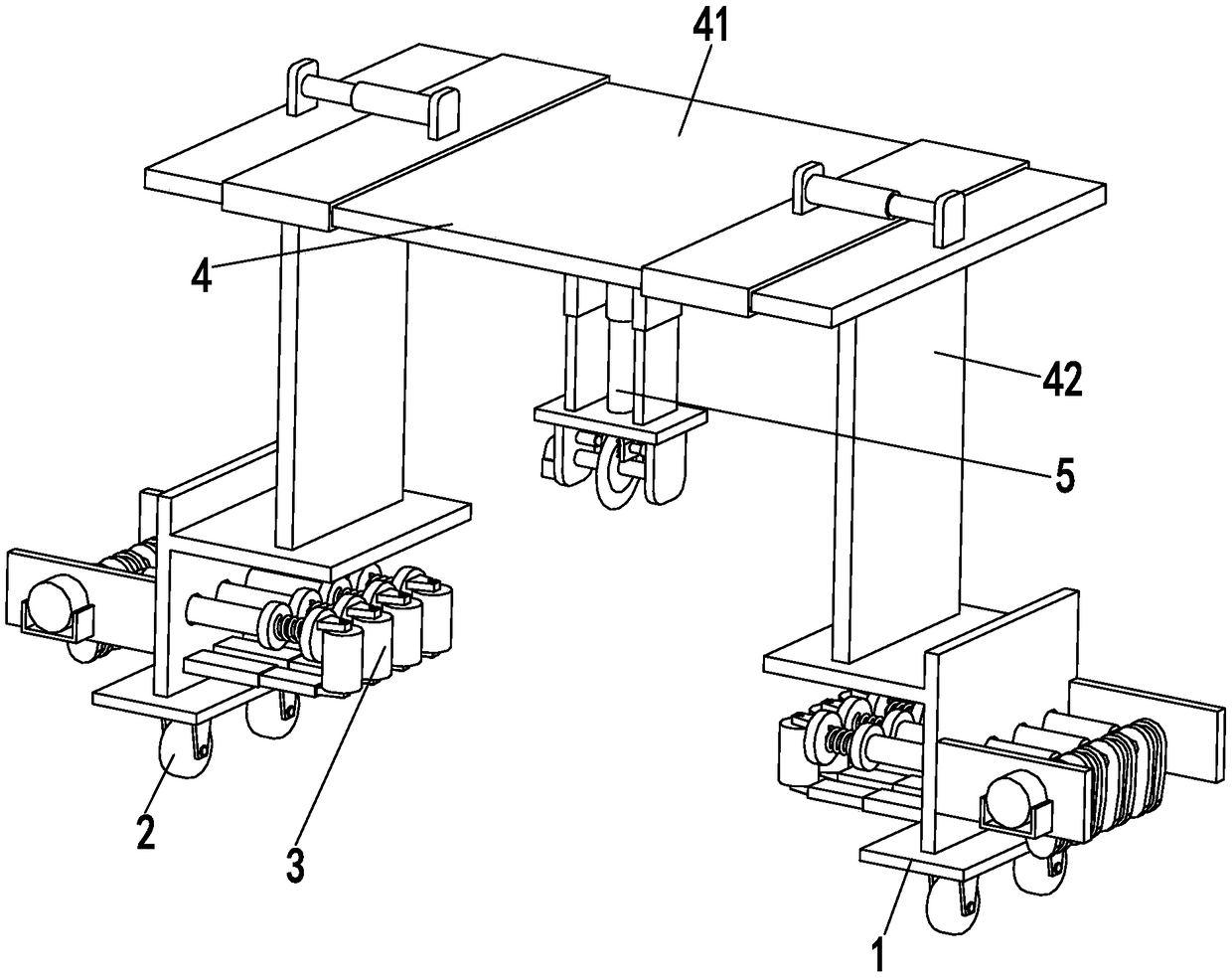

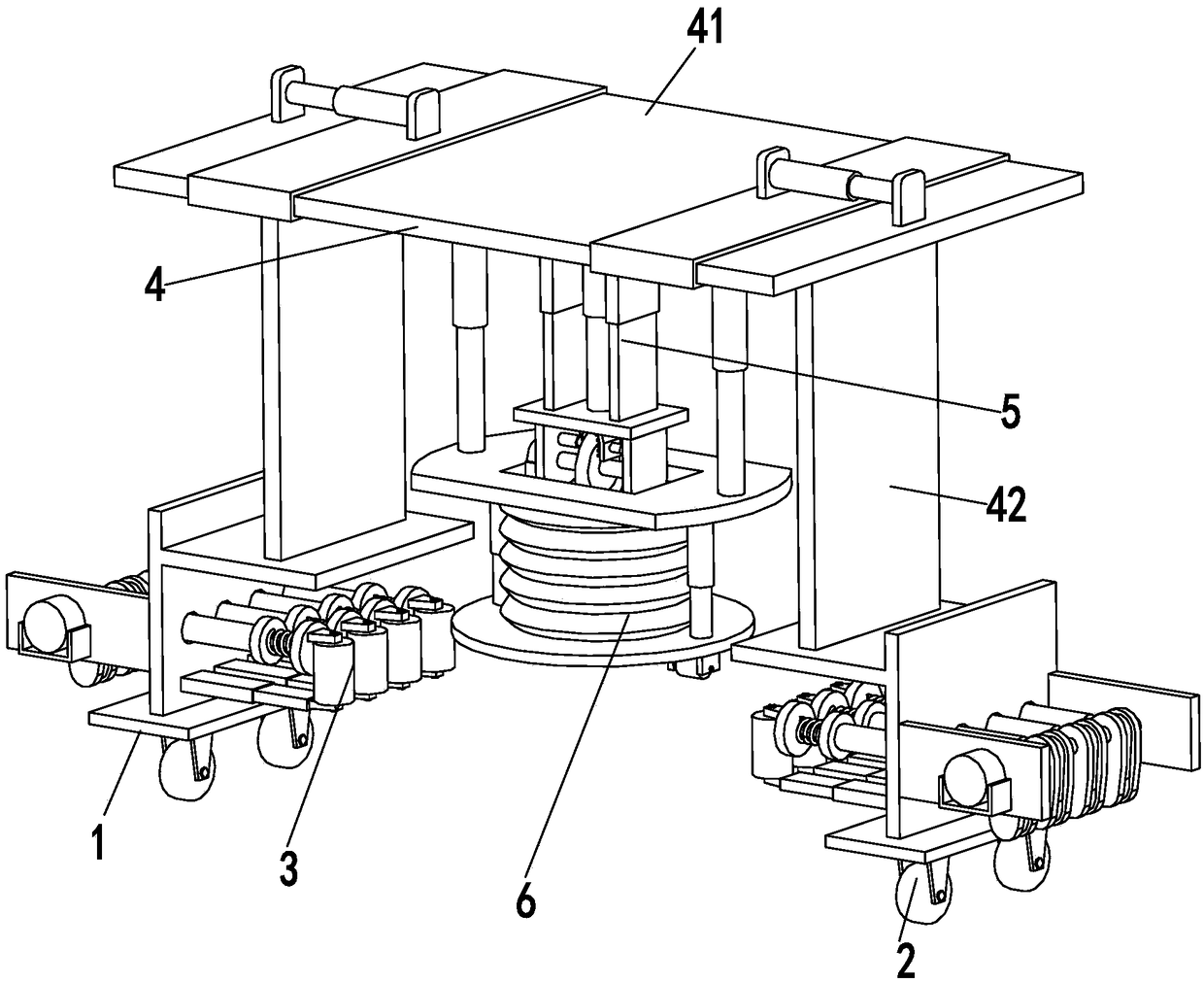

Asphalt concrete pavement longitudinal joint cutting equipment

ActiveCN108755369AGuaranteed cutting effectReduce labor costsRoads maintainenceLongitudinal contractionBaseboard

The invention relates to asphalt concrete pavement longitudinal joint cutting equipment. The equipment comprises baseboards, travelling wheels, assisting travelling devices, an installation rack and acutting device, wherein the number of the baseboards is two, the travelling wheels are installed at the lower ends of the baseboards, the assisting travelling devices are installed at the upper endsof the baseboards, the upper ends of the assisting travelling devices are connected with the installation rack, the cutting device is installed at the lower end of the installation rack, the assistingtravelling devices comprise power mechanisms and assisting travelling mechanisms, and the cutting device comprises a position adjusting mechanism and a cutting mechanism. By means of the equipment, the problems can be solved that in an existing curve longitudinal contraction joint cutting process, the working stability is poor, the cutting effect is not ideal, and potential safety hazards exist;the function of automation longitudinal joint cutting of an arc road can be achieved, and the equipment has the advantages that the working stability is good, the cutting effect is good, the safety ishigh and the like.

Owner:广东玮基建设工程有限公司

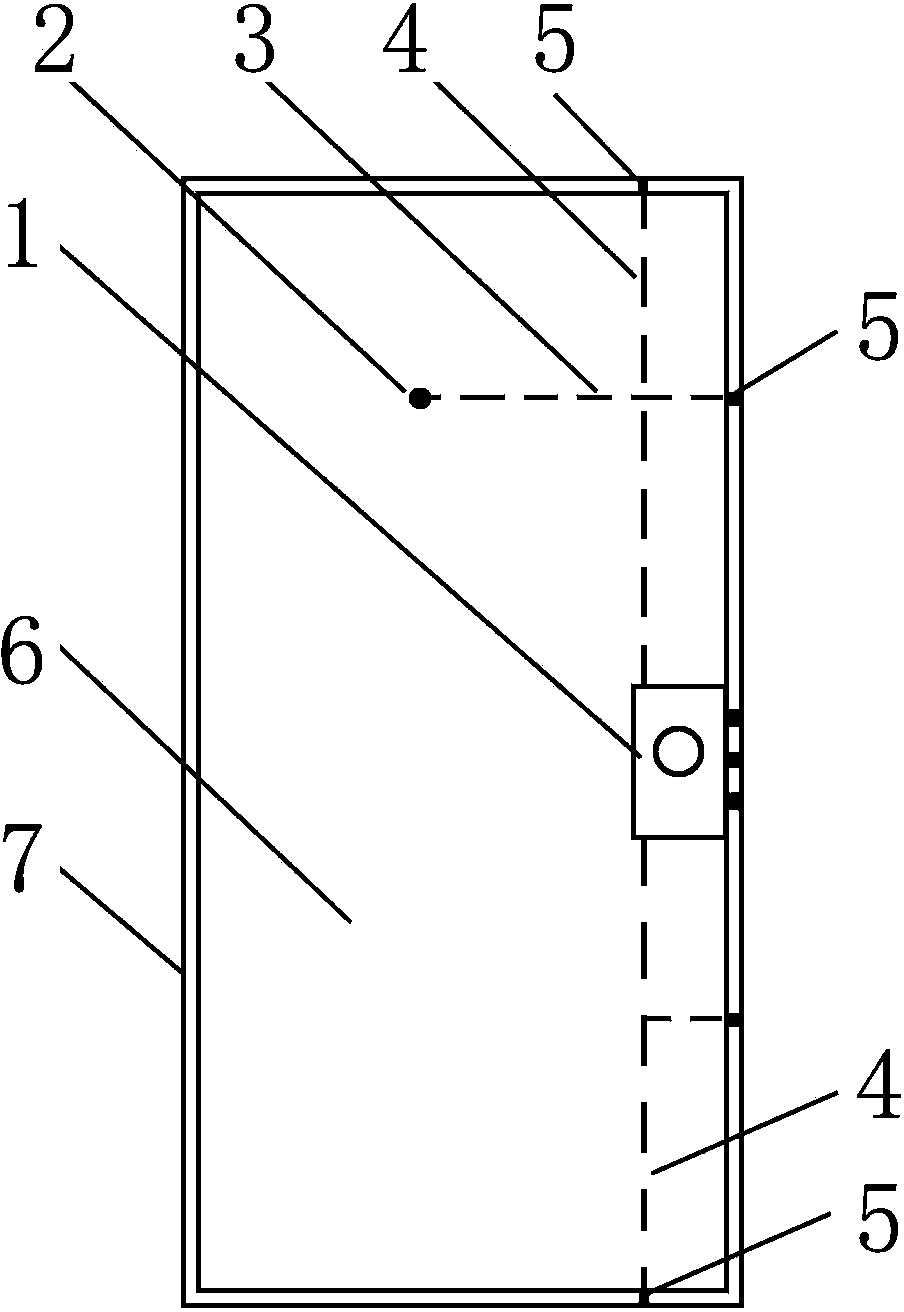

Antitheft door capable of automatically closing cat eye after being locked

InactiveCN103375107AImprove securityImprove anti-theft performanceBurglary protectionPeep-holesLongitudinal contractionEngineering

The invention provides an antitheft door capable of automatically closing a cat eye after being locked. The antitheft door comprises a door frame, a door, a vertical lock, a transverse lock bar, a longitudinal lock bar, a cat eye screen and a spring bolt, and is characterized in that the transverse lock bar (a longitudinal contraction bar) and the cat eye screen are in linkage with each other. The antitheft door has the advantages that when a user locks the antitheft door, the cat eye is automatically closed under the shielding effect of the screen, and accordingly is excellent in antitheft effect, and the problem that a criminal stretches a special tool into an existing door from a mounting through hole to unlock the existing door after damaging a light-transmittance element of an existing cat eye can be effectively solved; the safety coefficient of the cat eye of the antitheft door can be increased, accordingly, the antitheft performance of the antitheft door is improved, and the antitheft door can be used easily and conveniently.

Owner:林辉玉

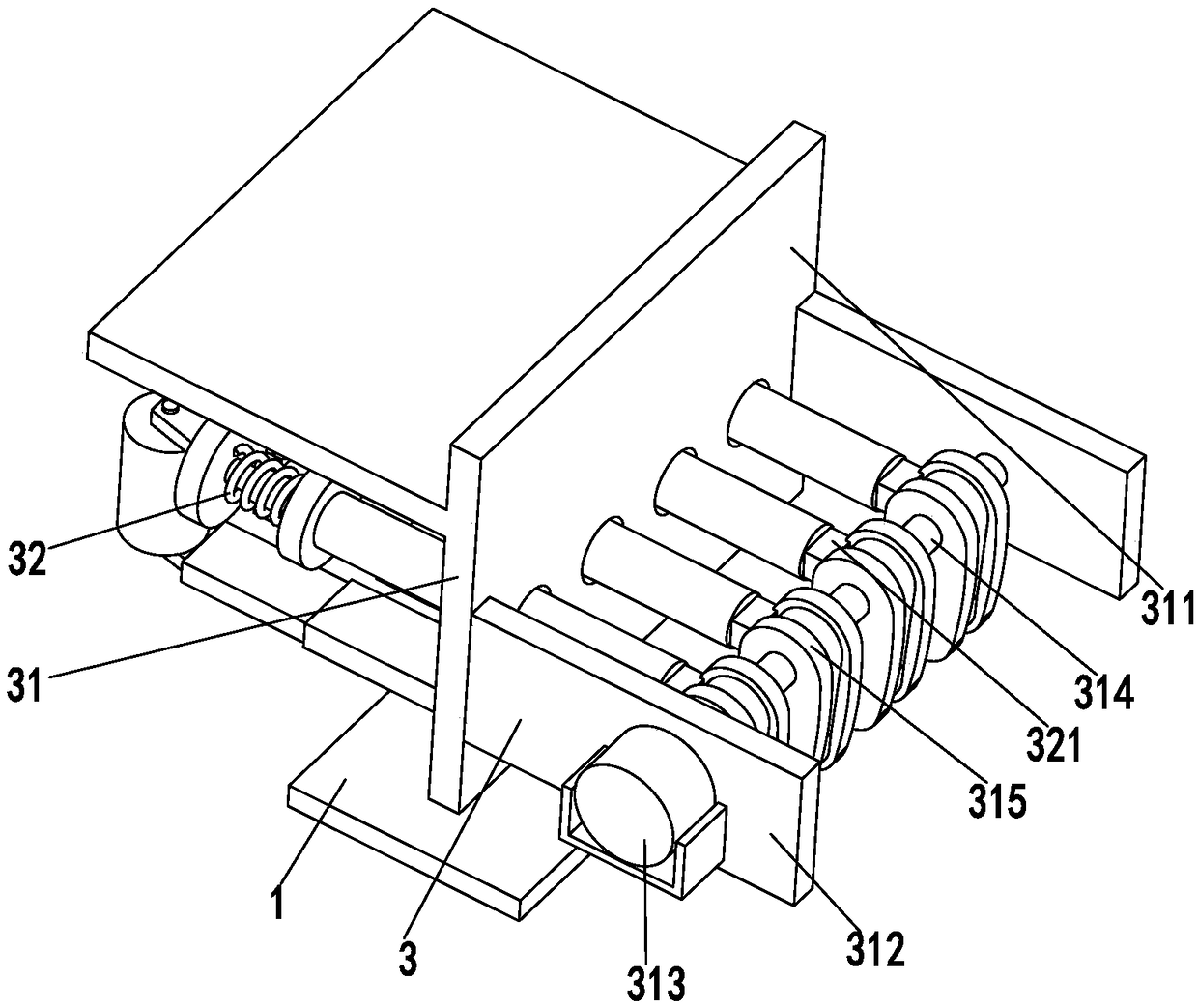

Longitudinal contraction joint cutting machine for asphalt concrete pavement

ActiveCN108797294AGuaranteed cutting effectReduce labor costsRoads maintainenceLongitudinal contractionRoad surface

The invention relates to a longitudinal contraction joint cutting machine for asphalt concrete pavements. The longitudinal contraction joint cutting machine comprises two bottom plates, traveling wheels, traveling assisting devices, a mounting frame, a cutting device and a protective device, wherein traveling wheels are mounted at the lower ends of the two bottom plates; the traveling assisting devices are mounted on the upper ends of the bottom plates; the upper ends of the traveling assisting devices are connected to the mounting frame; the cutting device is mounted at the lower end of the mounting frame; the protective device is arranged outside the cutting device; the protective device is mounted at the lower end of the mounting frame; and the traveling assisting devices comprise powermechanisms and traveling assisting mechanisms. The longitudinal contraction joint cutting machine for the asphalt concrete pavements is capable of solving the problems of poor working stability, unsatisfactory cutting effect, heavy dust, hidden dangers and the like in the existing longitudinal contraction joint cutting process of bends, realizing the function of automatic longitudinal contractionjoint cutting of the bends, and achieving the advantages of good working stability, good cutting effect, light dust, high safety and the like.

Owner:金华正方机械设备有限公司

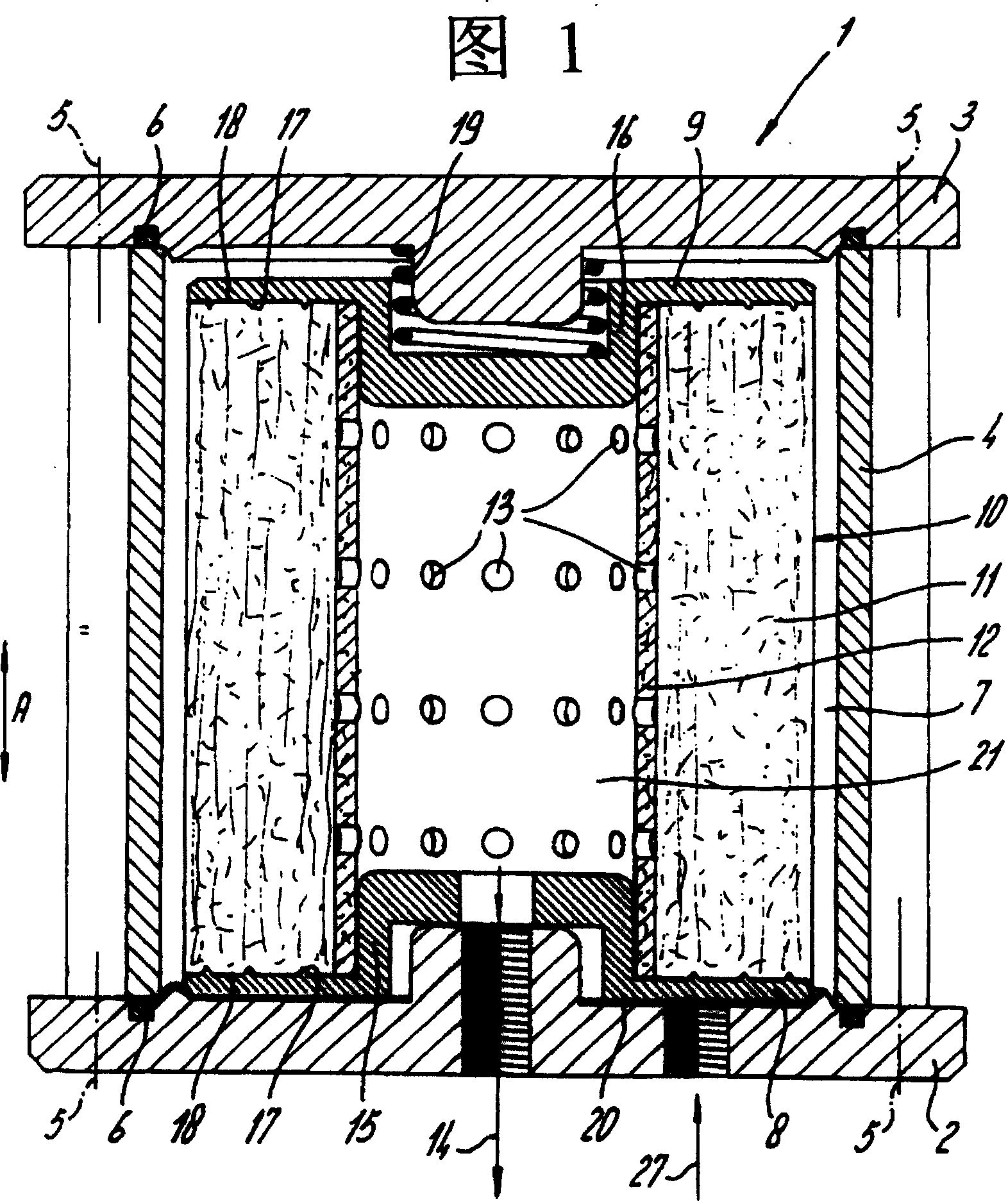

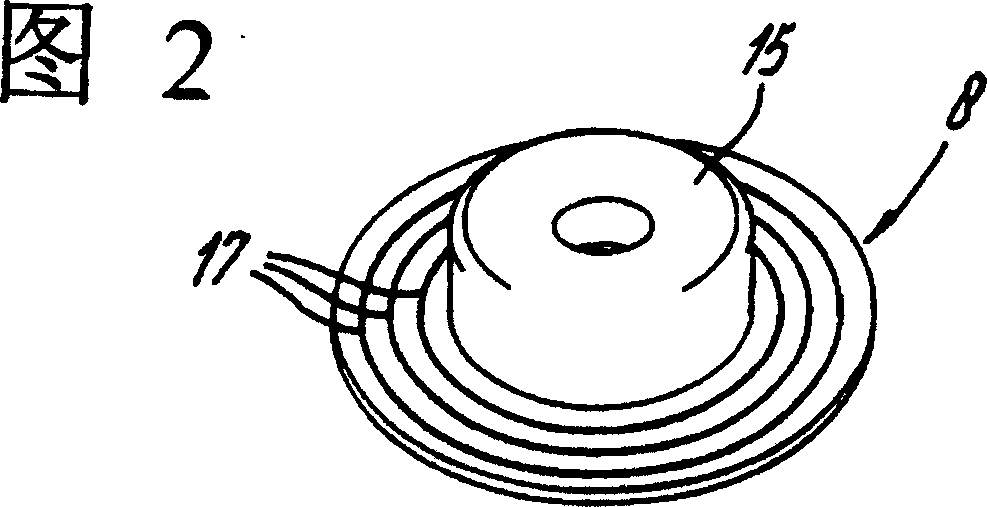

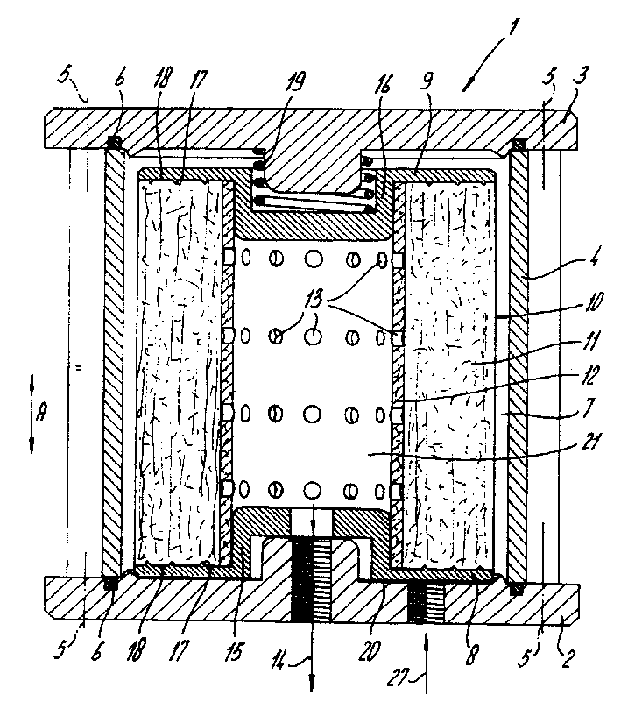

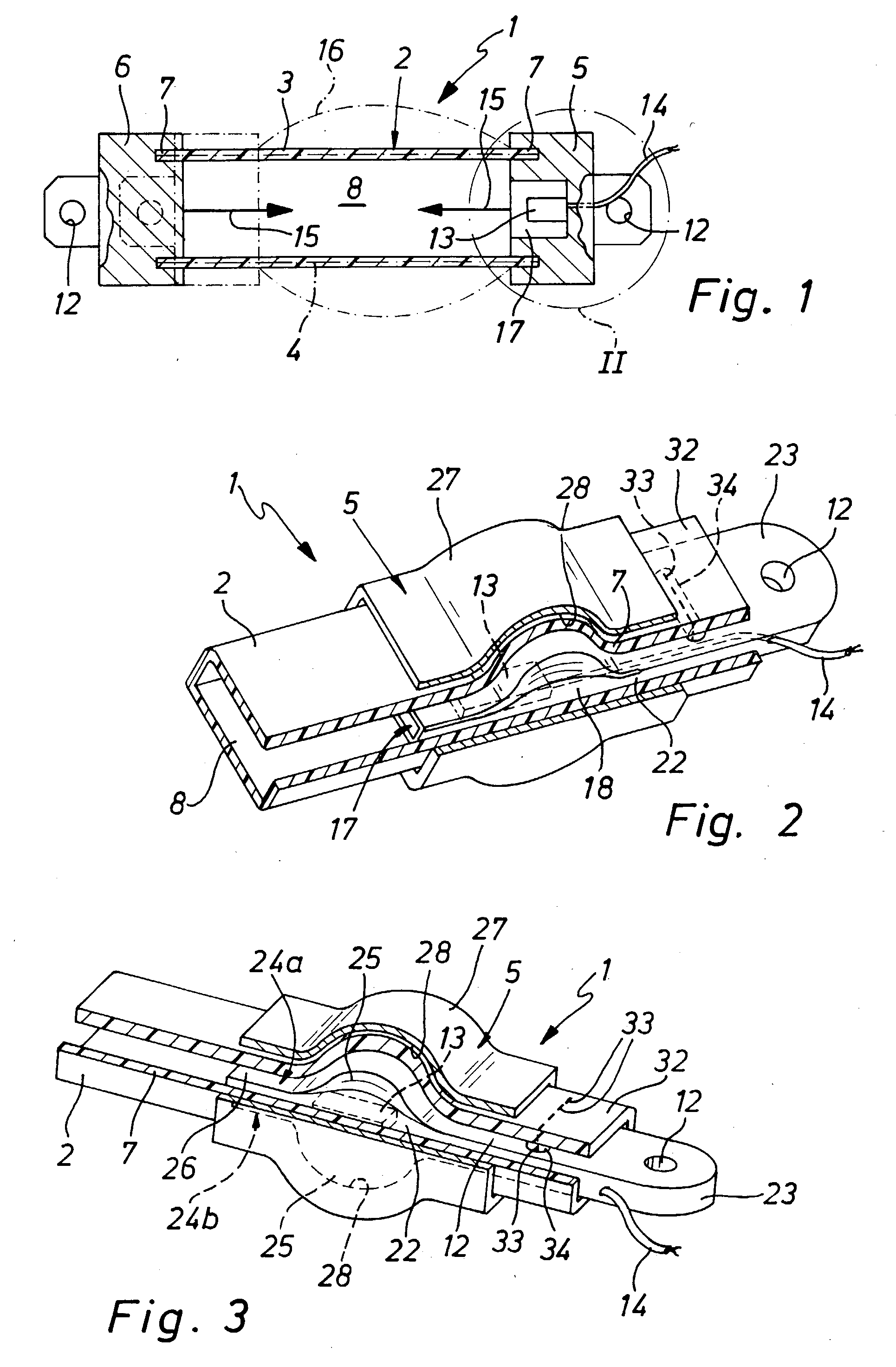

Filter device for microfiltration of oil

InactiveCN1224441CEasy to fixPositive displacement pump componentsGear lubrication/coolingAutomatic transmissionLongitudinal contraction

The invention relates to a filter device for microfiltration of oil, in particular for use in engines, automatic transmissions and hydraulic applications. The filter device comprises a tubular microfilter cartridge through which medium can flow in the transverse direction and which has open ends. This filter cartridge is accommodated in a filter chamber which is enclosed by a filter housing and is accommodated between two end closure elements, between which the filter cartridge is clamped under prestress. On their surface facing towards the filter cartridge the end closure elements are provided with at least one rib which extends in the transverse circumferential direction of the filter cartridge. The holding means comprise a spring which acts with prestress on one of the end closure elements, in such a manner that his closure element follows the end wall which it adjoins in the event of longitudinal expansion and also in the event of longitudinal contraction.

Owner:NTZ INT HLDG

Gas operated contraction drive

InactiveUS20030194264A1Improved response behaviorImprove operating ratePyrotechnical actuatorsRopes and cables for vehicles/pulleyGas generatorLongitudinal contraction

A gas operated contraction drive with a contractible hose, which undergoes longitudinal contraction when a working space defined by it is subjected to a pressurizing drive gas. The contractible hose is fitted with at least one pyrotechnic gas generator.

Owner:FESTO AG & CO KG +1

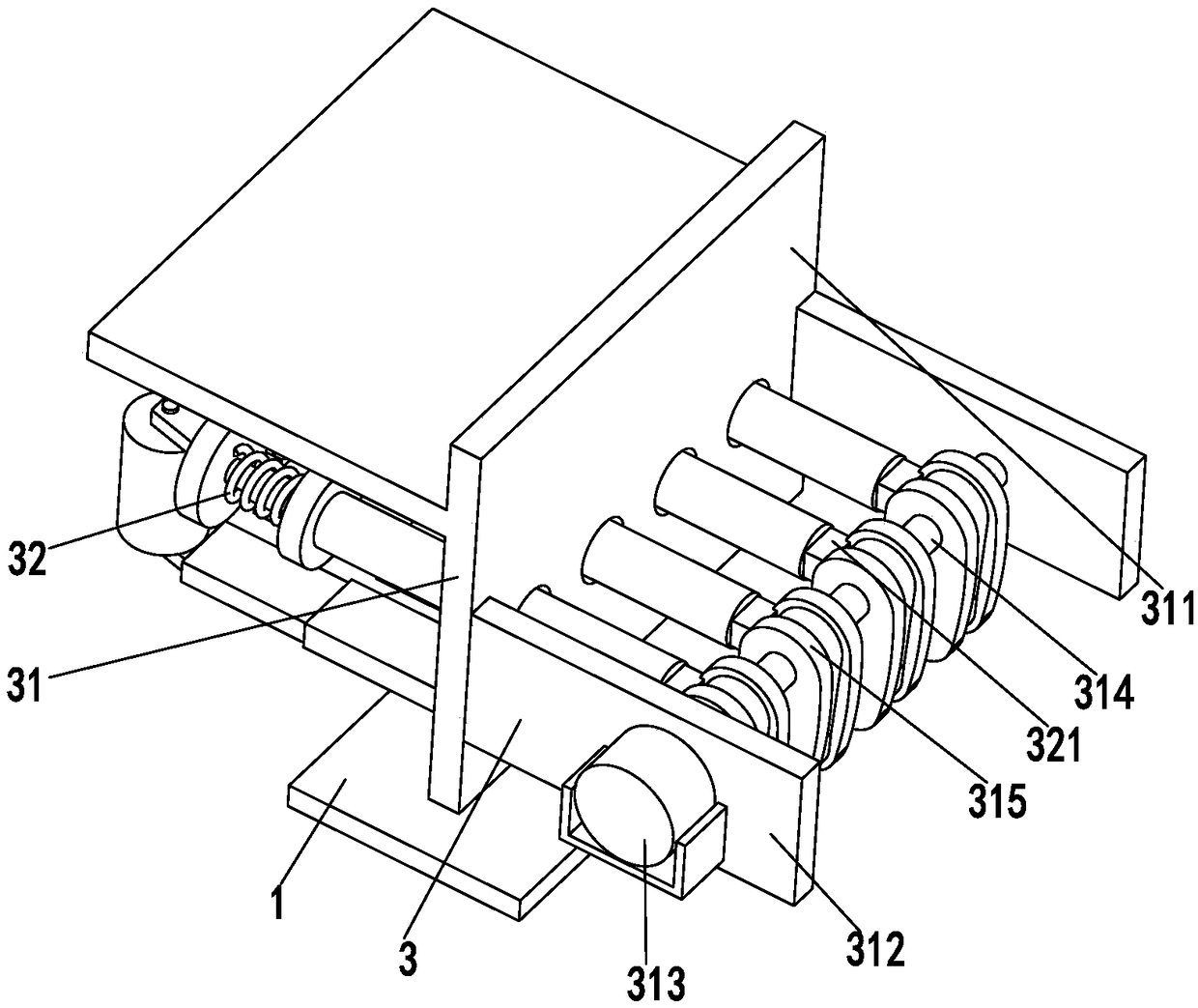

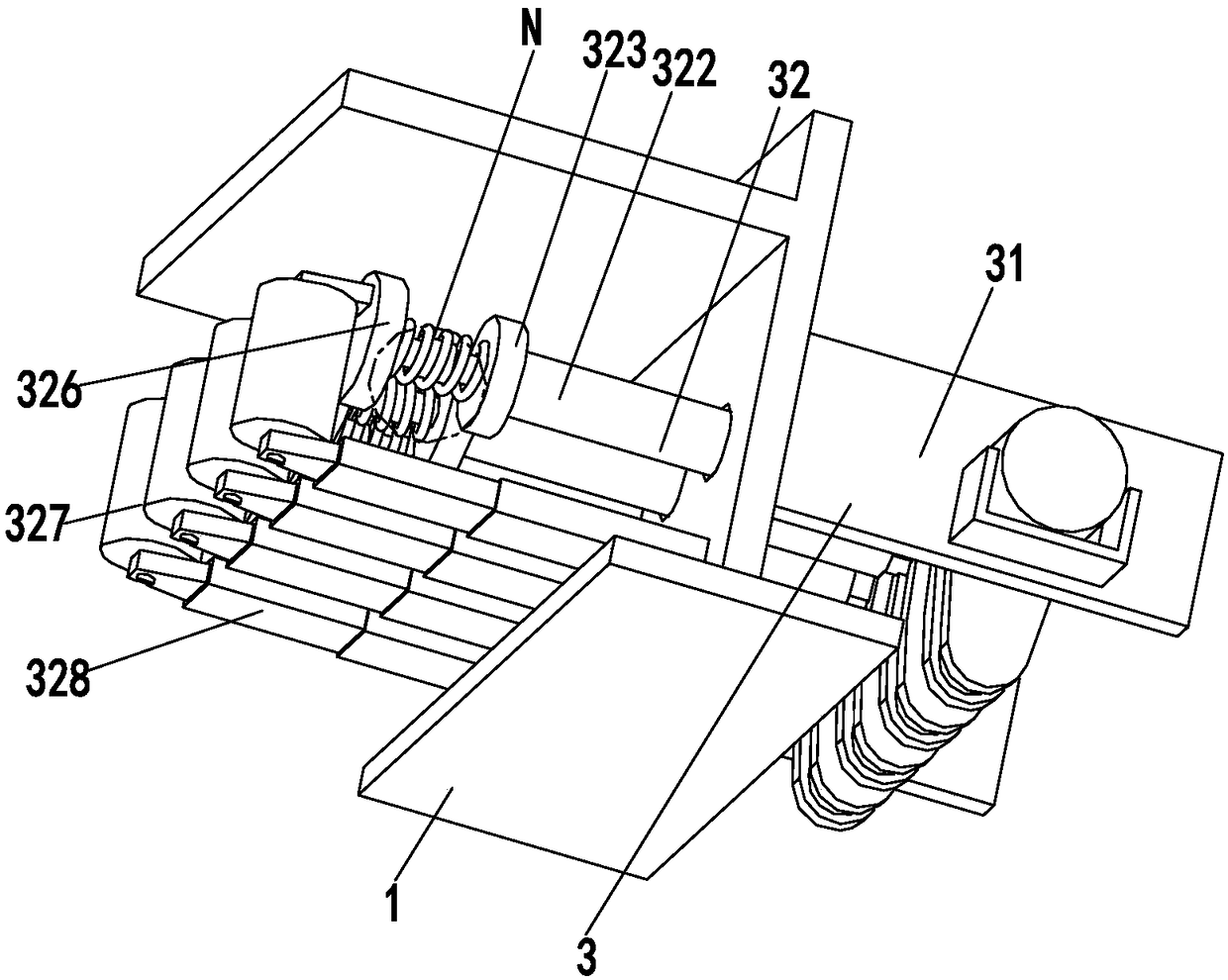

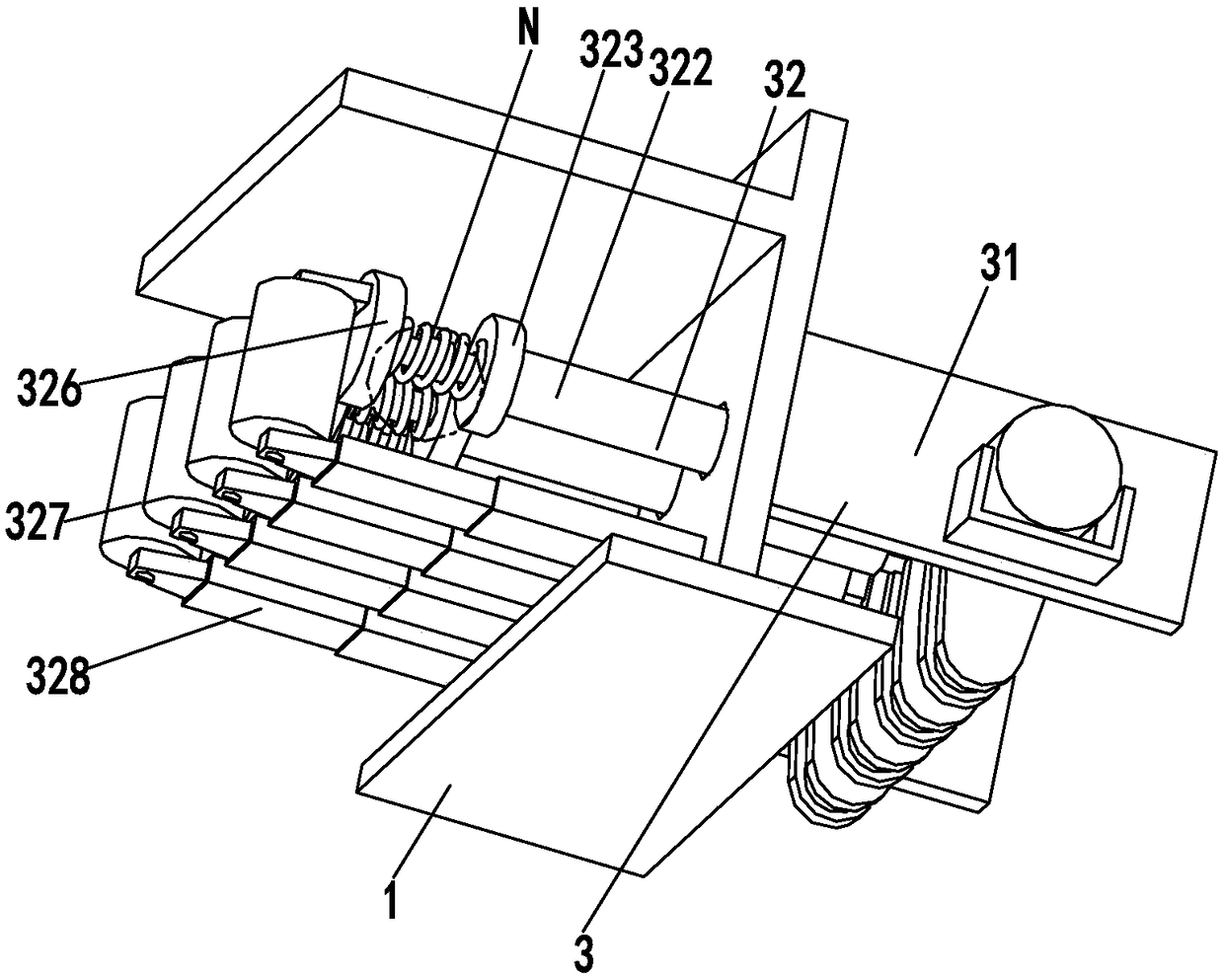

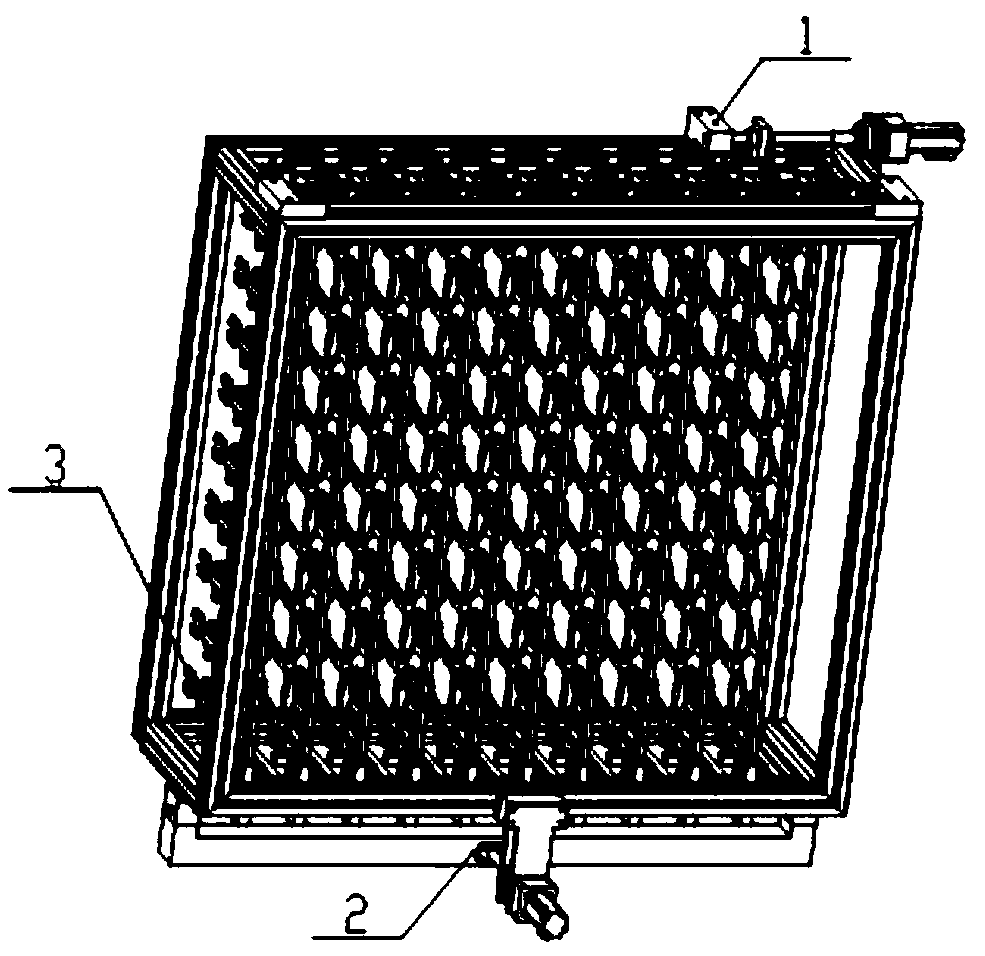

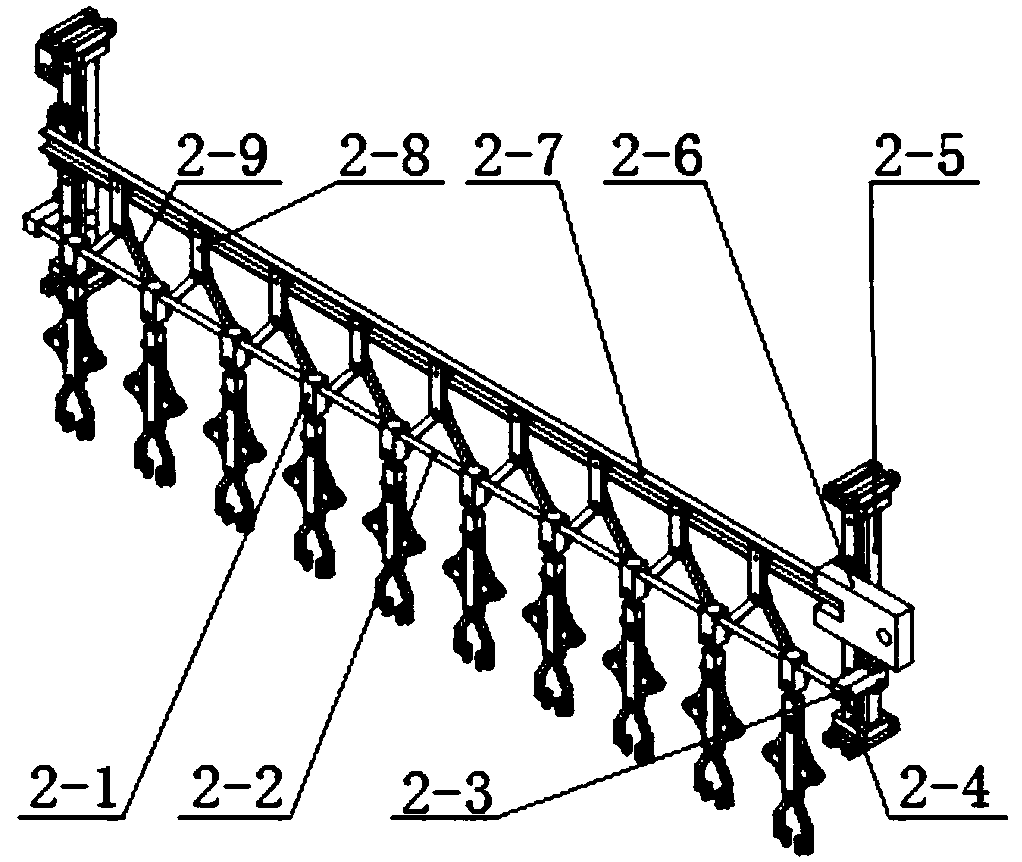

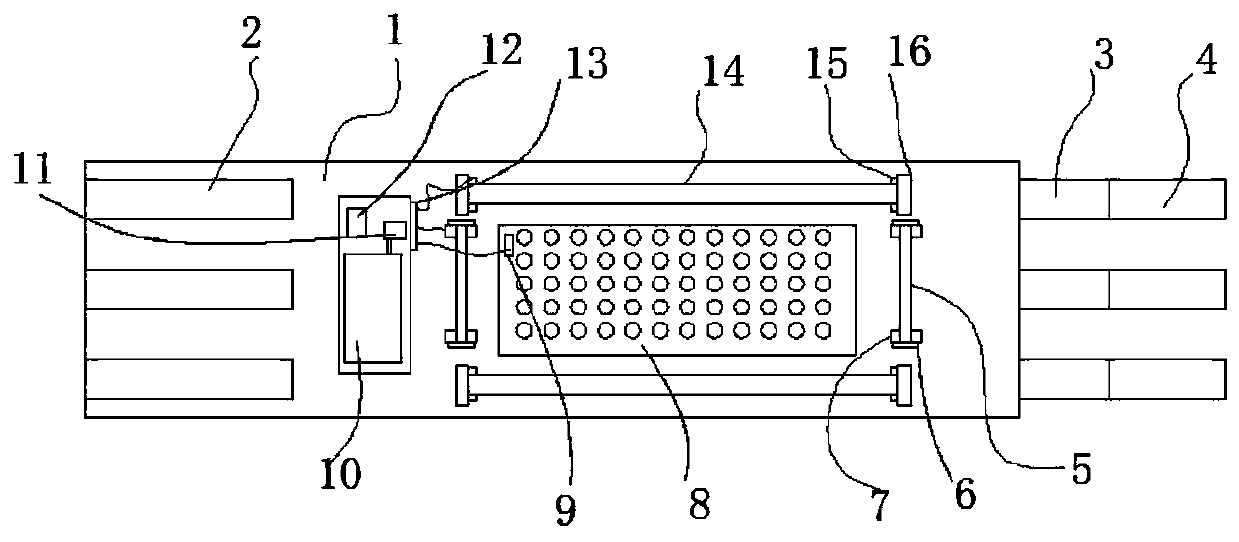

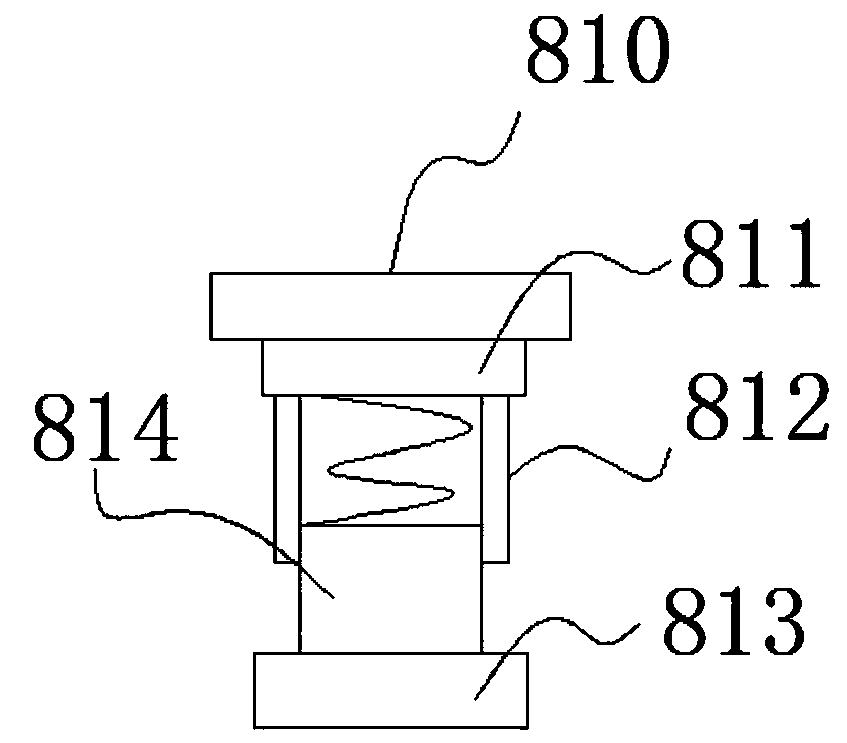

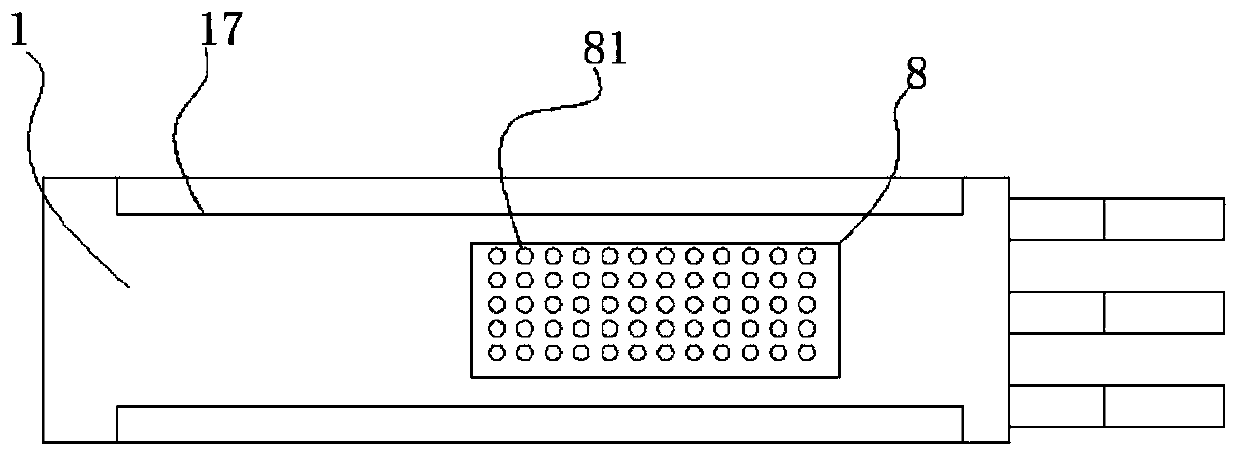

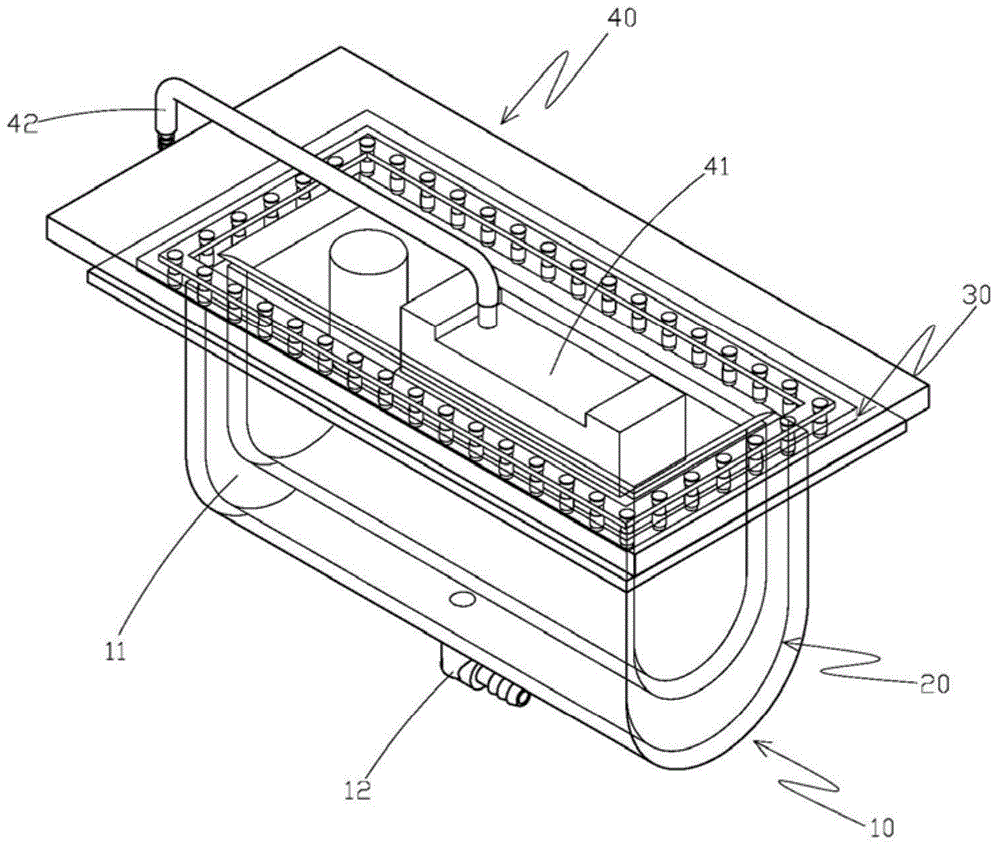

Ordered small particle grabbing and contraction device

ActiveCN109335094AAchieve orderly crawlingAchieve shrinkagePackagingParticulatesLongitudinal contraction

The invention discloses an ordered small particle grabbing and contraction device. The ordered small particle grabbing and contraction device comprises a longitudinal contraction assembly, a transverse contraction assembly and a small particulate matter clamping assembly; the small particulate matter clamping assembly is fixed to compacts on the lower parts of shear-fork mechanisms of the transverse contraction assembly in a threaded connection mode; the transverse contraction assembly is connected with longitudinal contraction assembly through the shear-fork mechanisms at the two ends, and used for avoiding the influence of transverse and longitudinal movement interference; the small particulate matter clamping assembly grabs orderly-arrayed small particulate matter with the great distance; the transverse contraction assembly acts to realize transverse contraction; after the action of the transverse contraction assembly is completed, the longitudinal contraction assembly starts to actto realize longitudinal contraction; and after the three actions are completed, the whole contraction process is completed. According to the ordered small particle grabbing and contraction device, ordered grabbing and contraction of the small particulate matter can be achieved, positioning is accurate, the grabbing efficiency is high, and a large quantity of labor costs are saved.

Owner:WUHAN POLYTECHNIC UNIVERSITY

High-pressure flame retardant single-wall heat-shrinkable pipe and preparation method thereof

ActiveCN101701090AMake up for the shortcomings of not being able to waterproof and sealHave all the performanceCable junctionsPolyolefinLongitudinal contraction

The invention relates to a heat-shrinkable pipe, in particular to a high-pressure flame retardant single-wall heat-shrinkable pipe and a preparation method thereof. The high-pressure flame retardant single-wall heat-shrinkable pipe comprises wall materials. The wall materials comprise the following components in parts by mass: 90 parts of polyolefin mixed resin, 10 parts of auxiliary agent and 30 parts of flame retardant agent. The preparation method comprises the steps of preparing, extruding, irradiating, expanding and moulding inner wall materials of a flame retardant single-wall heat-shrinkable pipe. Compared with a traditional shrinkable pipe, the invention has the technical characteristic of flame retardance of the wall materials, can be applied to high voltage of 35kV, has all use performances of a common heat-shrinkable pipe and the performances of water prevention, seal, moisture prevention, corrosion prevention, and the like, completely meets the ROHS environmental-friendly requirement of nations, such as European Union, and the like and has the advantages of low-temperature shrinkage, stable expansion for 3 times to 4times, low longitudinal shrinkage rate, and the like.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

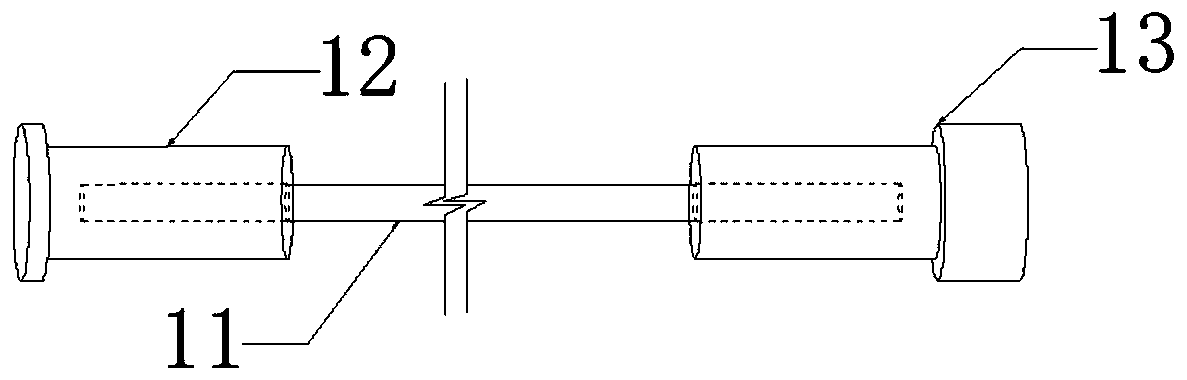

Instrument capable of reading numerical value of sensor for measuring muscular movement strength of human body

InactiveCN110074760AIntensity observationDiagnostic signal processingSensorsMuscle strengthLongitudinal contraction

The invention discloses an instrument capable of reading a numerical value of a sensor for measuring muscular movement strength of human body. The instrument comprises a main body; binding componentsfor binding arms are arranged on left and right ends of the main body; a control panel and a collecting module are arranged on the main body; the collecting module is electrically connected with the control panel through a data line and is used for collecting data of human body; the collecting module comprises a first detecting module, a second detecting module, a pressure detecting module and a scanning module; the first detecting module is used for detecting lateral contraction of muscle; the second detecting module is used for detecting longitudinal contraction of muscle; the pressure detecting module is used for detecting local strength of muscle; the scanning module is used for scanning arm shape. The instrument provided by the invention is designed in order to meet the present requirements; an AR image processor is adopted for processing the collected information into an AR image; the processed AR image is displayed by an AR display screen; information about horizontal tension and muscle surface pressure is displayed and processed in the displayed AR image, so that the muscle strength can be directly observed; the instrument is high in practicability.

Owner:PACIFIC FUTURE TECH (SHENZHEN) CO LTD

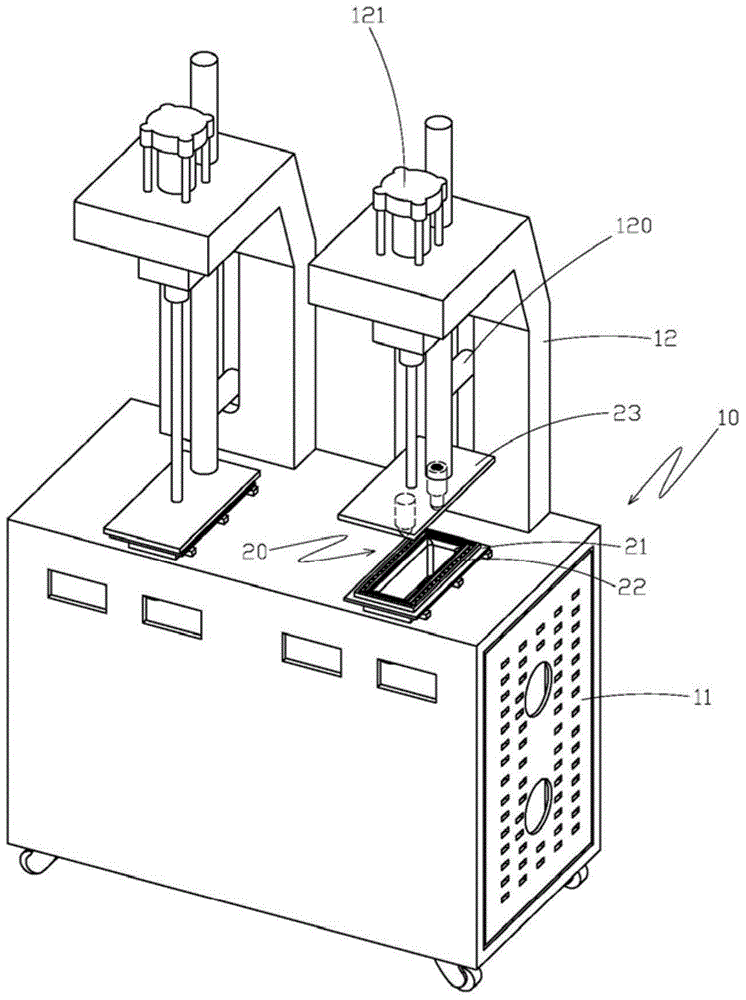

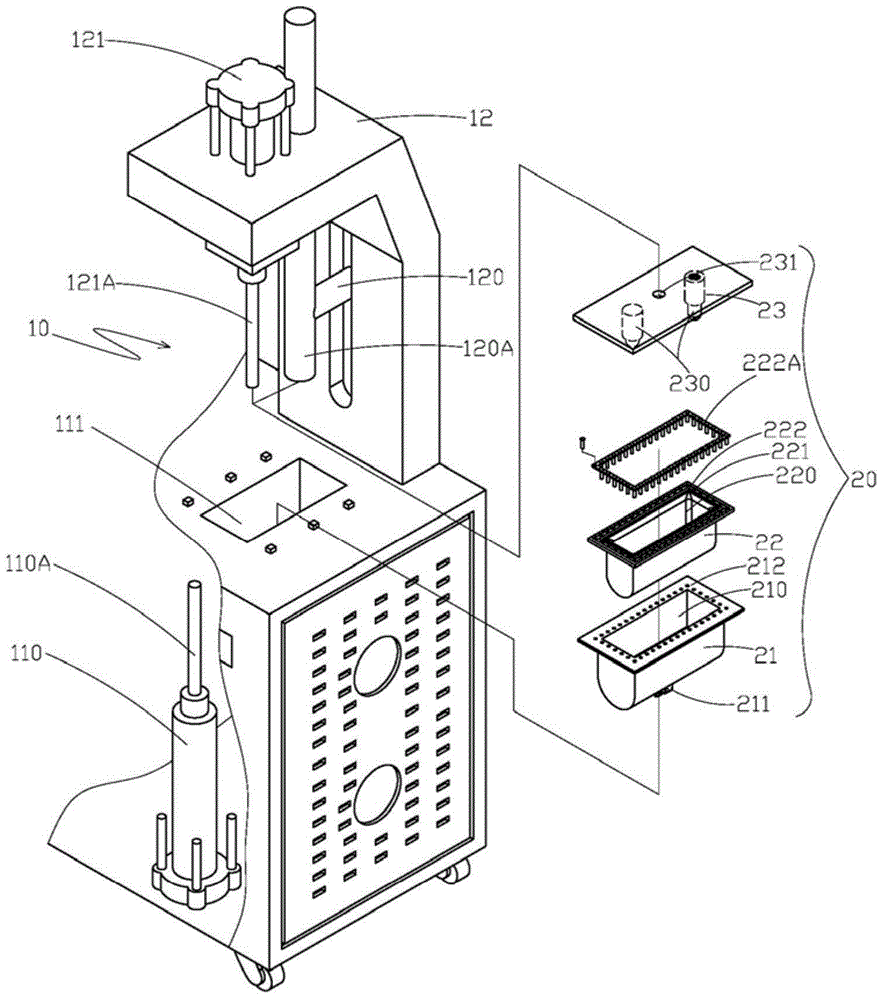

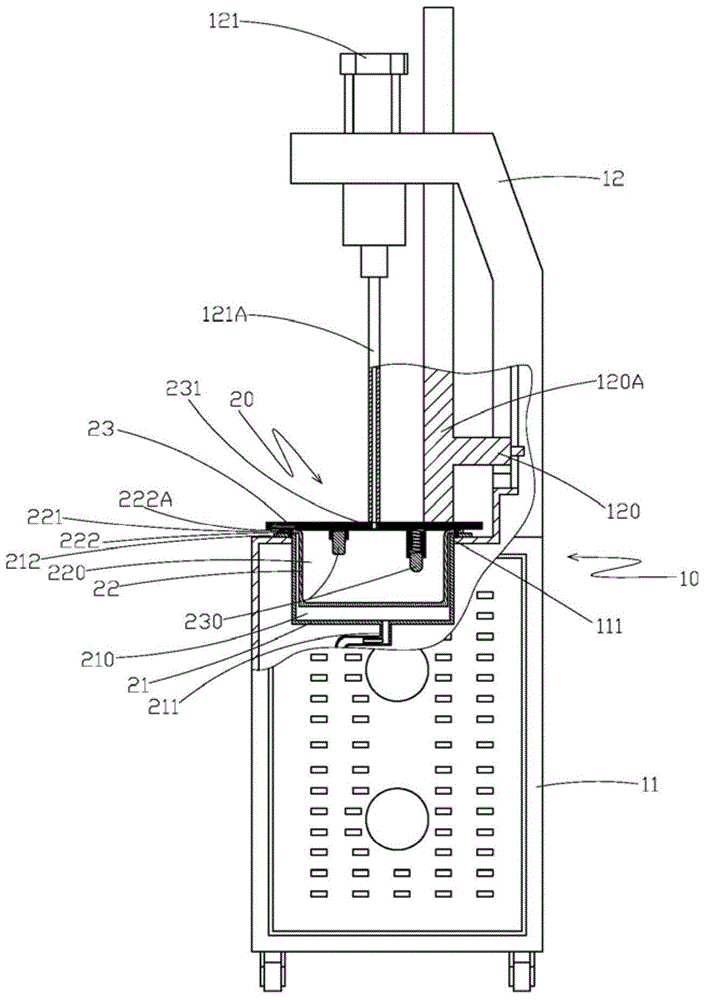

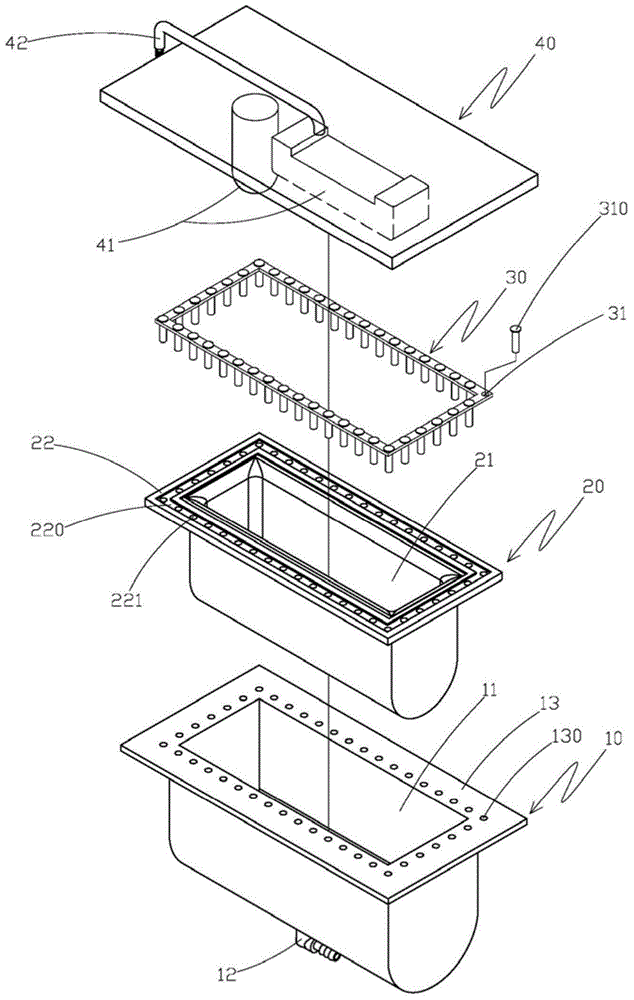

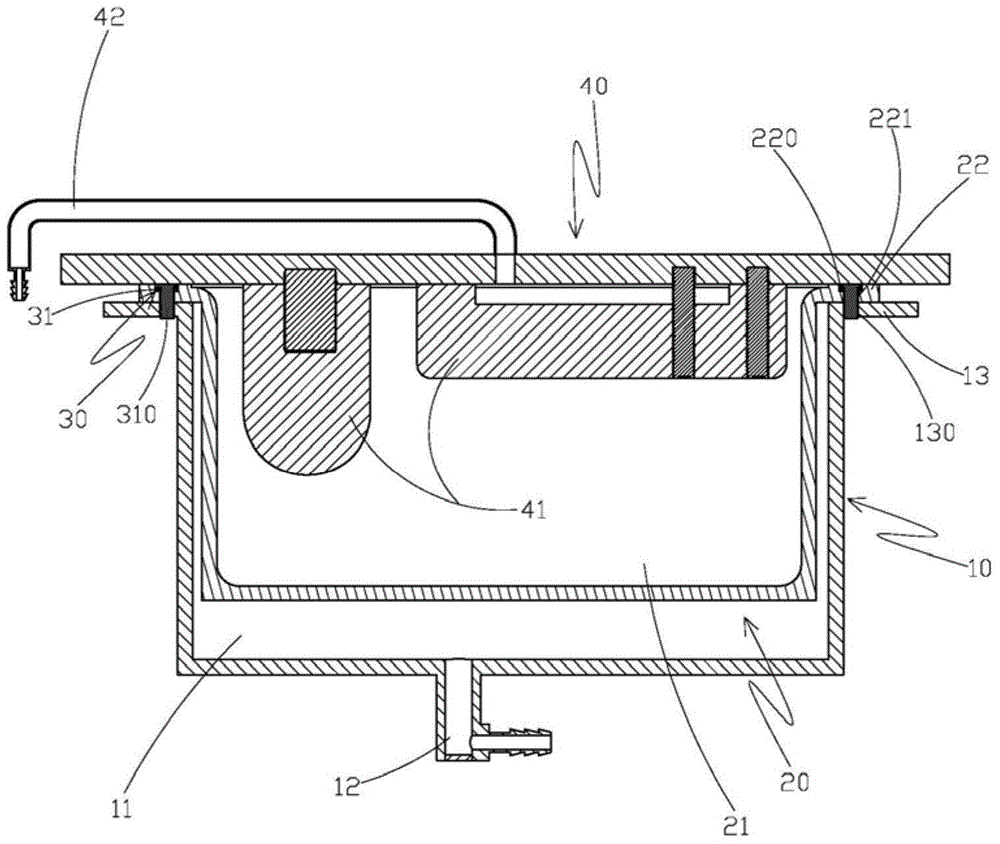

Vacuum sole pressing shoe making machine structure

InactiveCN104799492AImprove processing stabilityGood combination stabilityShoe gluingLongitudinal contractionMachining process

The invention discloses a vacuum sole pressing shoe making machine structure. A shoe body is placed into a containing groove in an elastic container, air is guided into an air inlet duct of a base body through an inflation pump arranged in a base, so that the elastic container is pushed by the guided air, the air is sucked by a suction pipe of a suction pump of a cantilever portion from an exhaust guide hole in a top cover, so that the elastic container is contracted into a vacuum state, gumming is arranged on the top face of a shoe sole, the shoe body is squeezed when the elastic container is contracted, the shoe sole and an upper of the shoe body are pressed by lateral and longitudinal contraction force, so that the shoe sole and the upper are stably combined, looseness of joint edges of the shoe sole and the upper can be avoided, the problems such as gum overflow and shoe body deformation caused by pressurization in the machining process are solved, and better machining stability and combining stability are achieved.

Owner:东莞市良强机械有限公司

Vacuum sole pressing shoe making device structure

The invention discloses a vacuum sole pressing shoe making device structure. A shoe body containing a shoe last is placed into a containing groove in an elastic container, air is guided into an air inlet duct of a base body, so that the elastic container is pushed by the guided air, the air is sucked from an exhaust duct in a top cover, so that the elastic container is contracted into a vacuum state, gumming is arranged on the top face of a shoe sole, the shoe body is squeezed when the elastic container is contracted, the shoe sole and an upper of the shoe body are pressed by lateral and longitudinal contraction force, so that the shoe sole and the upper are stably combined, looseness of joint edges of the shoe sole and the upper can be avoided, the problems such as gum overflow and shoe body deformation caused by pressurization in the machining process are solved, and better machining stability and combining stability are achieved.

Owner:东莞市良强机械有限公司

Semiconduction double-wall heat-shrinkable tube and preparation method thereof

InactiveCN101759906AImprove electrical performanceGood chemical propertiesCable junctionsPolyolefinHazardous substance

The invention relates to a heat-shrinkable tube, in particular to a semiconduction double-wall heat-shrinkable tube and a preparation method thereof. The semiconduction double-wall heat-shrinkable tube consists of an outer wall material and an inner wall material, wherein the outer wall material comprises the following components in parts by weight: 70 parts of first polyolefin mixed resin, 20 parts of first auxiliary agent and 10 parts of conductive carbon black; and the inner wall material comprises the following components in parts by weight: 70 parts of second polyolefin mixed resin, 30 parts of second auxiliary agent and 10 parts of conductive carbon black. The preparation method comprises the following steps of: preparing the inner and outer wall material of the double-wall heat-shrinkable tube; extruding; irradiating; expanding; and molding. Compared with the traditional heat-shrinkable tubes, the double-wall heat-shrinkable tube has the technical characteristics that the inner wall material can be water proof and air-tight; the outer wall material maintains good properties of electrical properties, chemical properties, and the like of ordinary heat-shrinkable tubes, not only has all use properties of the ordinary heat-shrinkable tubes, but also has the properties of waterproofing, air-tightness, damp proofing, anticorrosion, and the like, completely meets the requirement on environmental protection of the ROHS (Restriction of the use of certain Hazardous Substances) instruction of EU (European Union) countries, and the like and has the advantages of low-temperature shrinking, stable expansion from three to four times, low longitudinal shrinkage rate, and the like.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

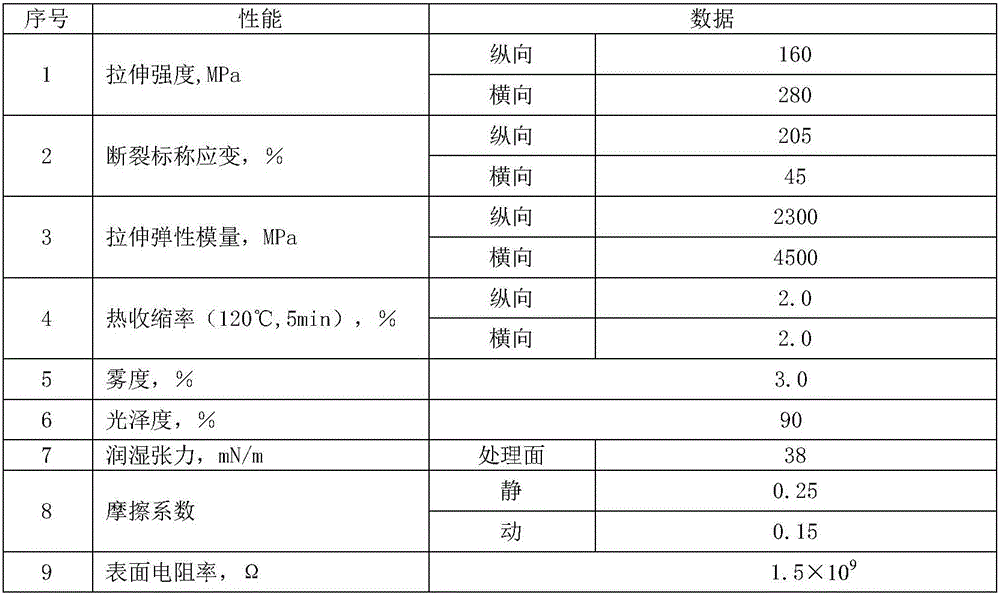

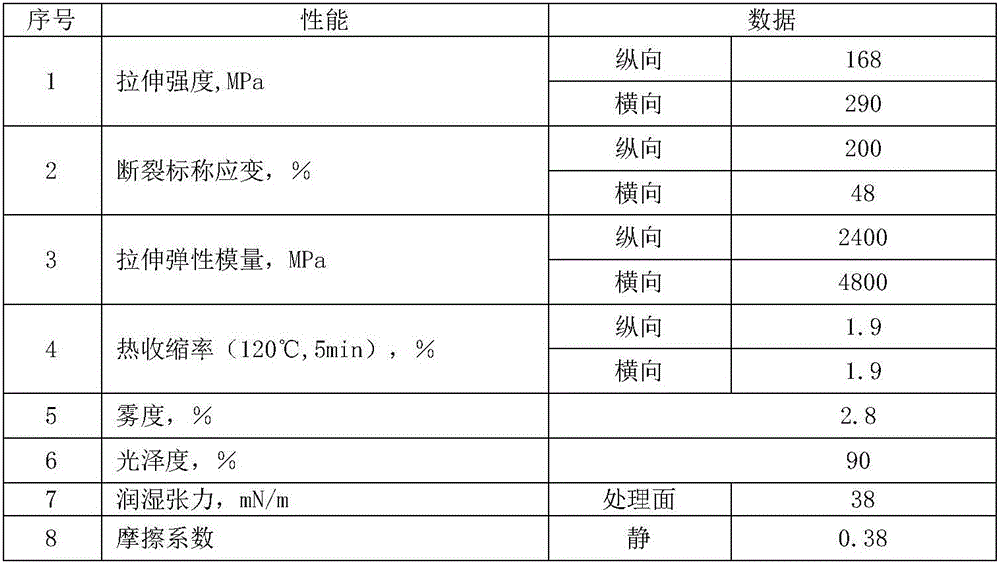

Heat balance BOPP film for mold internal heating attaching and manufacturing technology thereof

ActiveCN106079766AImprove thermal stabilityImprove static problemsLamination ancillary operationsSynthetic resin layered productsPolymer alloyManufacturing technology

The invention discloses a heat balance BOPP film for mold internal heating attaching and a manufacturing technology thereof. The heat balance BOPP film is composed of a core layer, an inner surface layer and an outer surface layer. The core layer is prepared from a stiffness increasing master batch and homo-polypropylene, wherein the content of the stiffness increasing master batch is 3-8 wt%; the inner surface layer is a corona treatment layer and is prepared from an anti-blocking master batch, a polymer alloy conductive master batch and homo-polypropylene, wherein the content of the anti-blocking master batch is 3-5 wt%, and the content of the polymer alloy conductive master batch is 5-10 wt%; the outer surface layer is prepared from an anti-blocking master batch, a polymer alloy conductive master batch and ethylene-propylene-butadiene copolymer, the content of the anti-blocking master batch is 3-5 wt%, and the content of the polymer alloy conductive master batch is 5-10 wt%. The heat balance BOPP film has the good heat stability, the transverse and longitudinal contraction rates are the same, and the film has the good attaching performance with a mold, and is strong in static electricity conduction capacity, excellent in printing performance and suitable for grasping operation of a mechanical arm.

Owner:ANHUI GUOFENG PLASTIC

Gas operated contraction drive

InactiveUS6871500B2Improve operating rateImprove responsePyrotechnical actuatorsRopes and cables for vehicles/pulleyLongitudinal contractionGas generator

Owner:FESTO AG & CO KG +1

Method and apparatus for restricting flow through an opening in the side wall of a body lumen, and/or for reinforcing a weakness in the side wall of a body lumen, while still maintaining substantially normal flow through the body lumen

A method for making a device for causing thrombosis of an aneurysm, wherein said device comprises a single elastic filament configurable between (i) an elongated, substantially linear configuration, and (ii) a longitudinally-contracted, substantially three-dimensional configuration, said method comprising:providing a sheet of shape memory material;producing a single filament, two-dimensional interim structure from said sheet of shape memory material;mounting said single filament, two-dimensional interim structure to a fixture so that said single filament, two-dimensional interim structure is transformed into said longitudinally-contracted, substantially three-dimensional configuration; andheat treating said single filament, two-dimensional interim structure while it is mounted to said fixture so as to produce said device in its longitudinally-contracted, substantially three-dimensional configuration.

Owner:CORNELL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com