Filter device for microfiltration of oil

A filter device and micro-filtration technology, which is applied in the direction of filtration separation, membrane filter, cartridge filter, etc., can solve problems such as device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

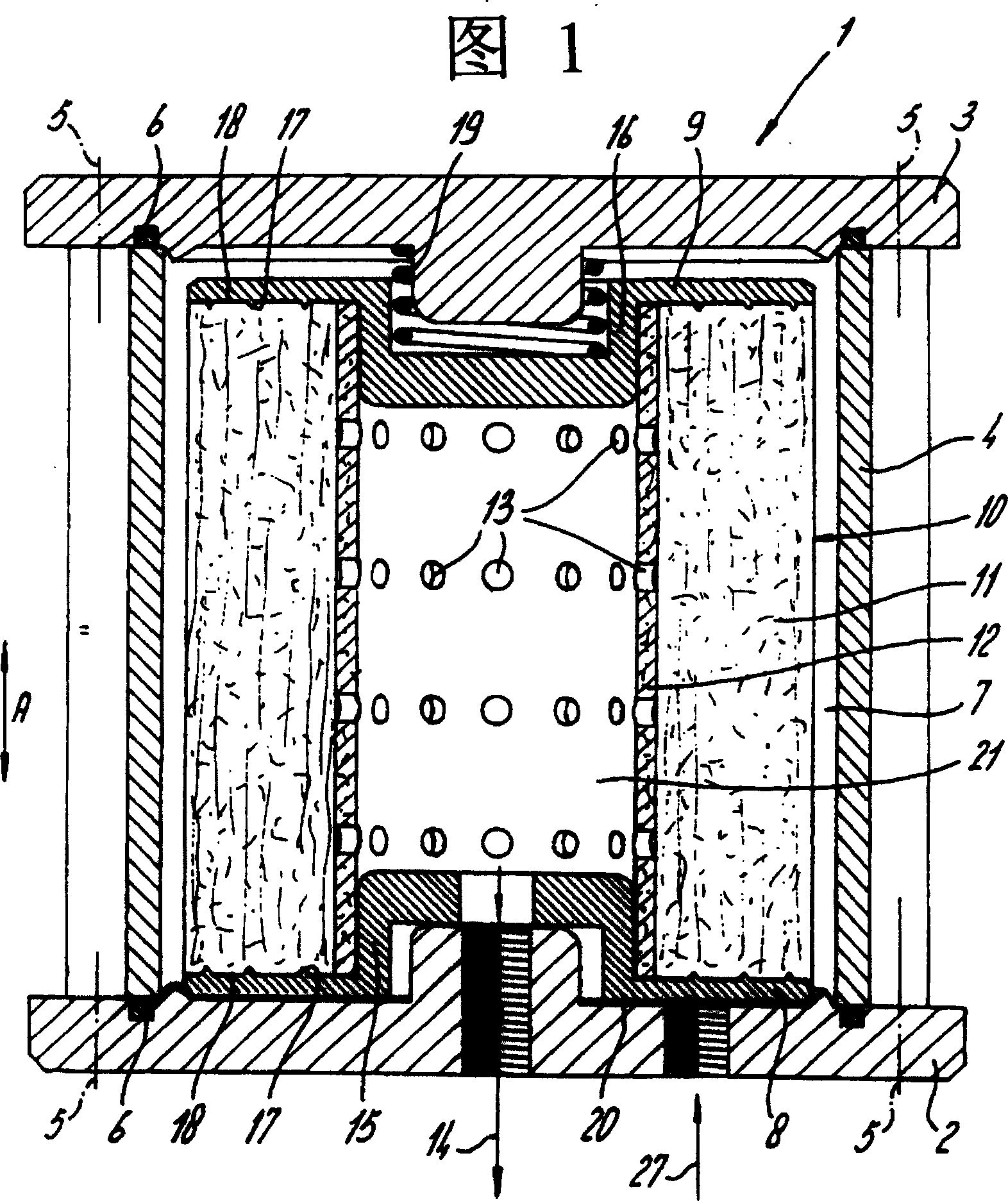

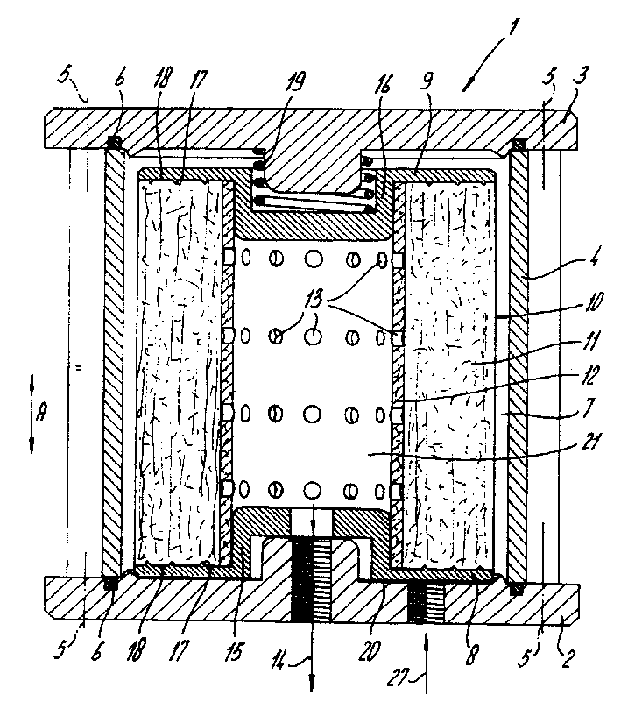

[0020] The filter device 1 according to the invention comprises a filter housing formed by a bottom plate 2, a top plate 3 and a cylindrical wall 4 located between the plates. Wherein the bottom plate 2 and the top plate 3 are connected to the cylindrical wall 4 by means of screws, which are schematically indicated by the axis 5 in the figure. To ensure a seal between the bottom plate 2 and the cylindrical wall 4 and between the top plate 3 and the cylindrical wall 4 , O-ring seals 6 are provided.

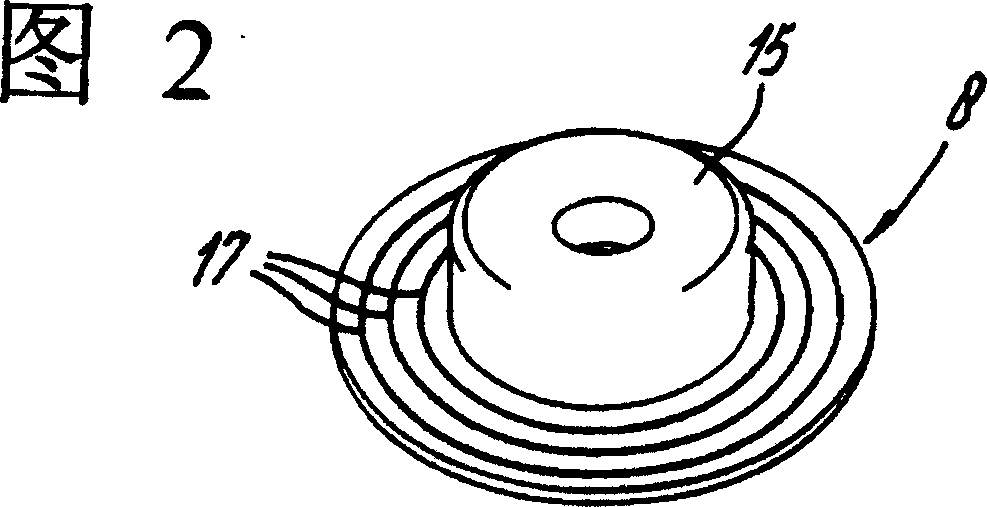

[0021] Inside the filter housing, there is a first or bottom sealing element 8 and a second or top sealing element 9 tightly mounted on the bottom plate 2 by means of drill-through hollow bolts provided with two sealing rings. A filter insert 10 is arranged between the end sealing elements 8 and 9 . The filter element 10 comprises filter paper 11 wound on a wound core 12, which may also comprise a large number of layers of tissue paper. The winding core 12 is provided with holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com