Vacuum sole pressing shoe making machine structure

A shoe-making machine and vacuum pressing technology, which is applied to shoe-making machinery, footwear, and adhesive shoe parts, etc., can solve the problems of reduced bonding stability, overflowing glue, shoe body deformation, etc., and achieves the effect of good processing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to enable your examiners to further understand the structure, features and other purposes of the present invention, the following preferred embodiments are attached to the drawings in detail as follows, but the embodiments described in this illustration are for illustration purposes only. It is not the only restriction on the patent application.

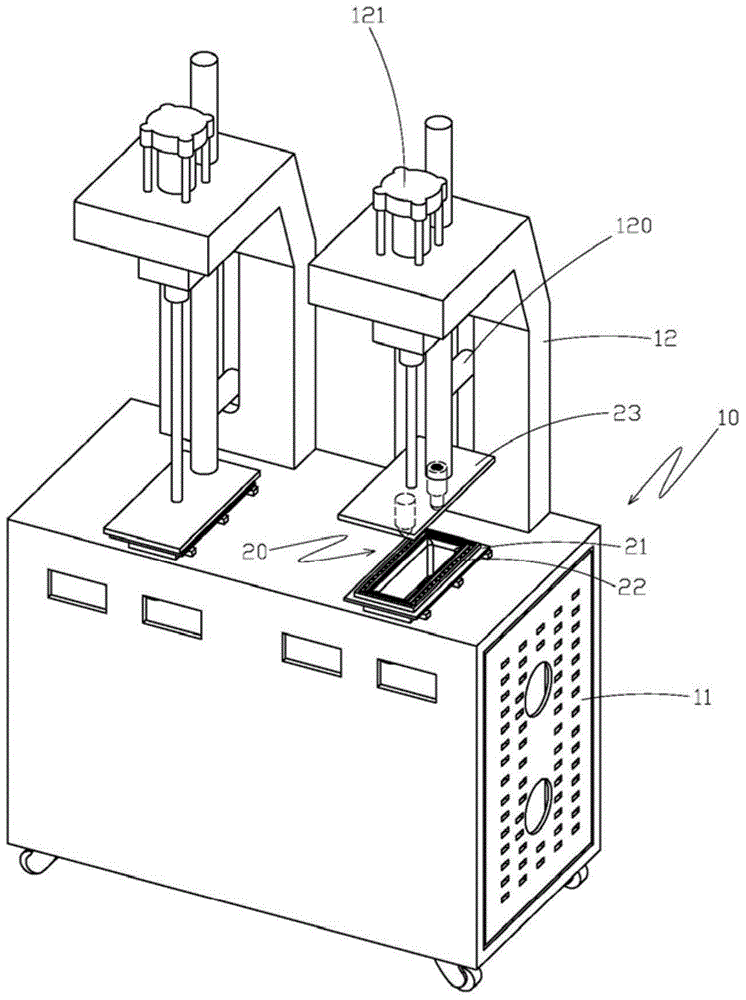

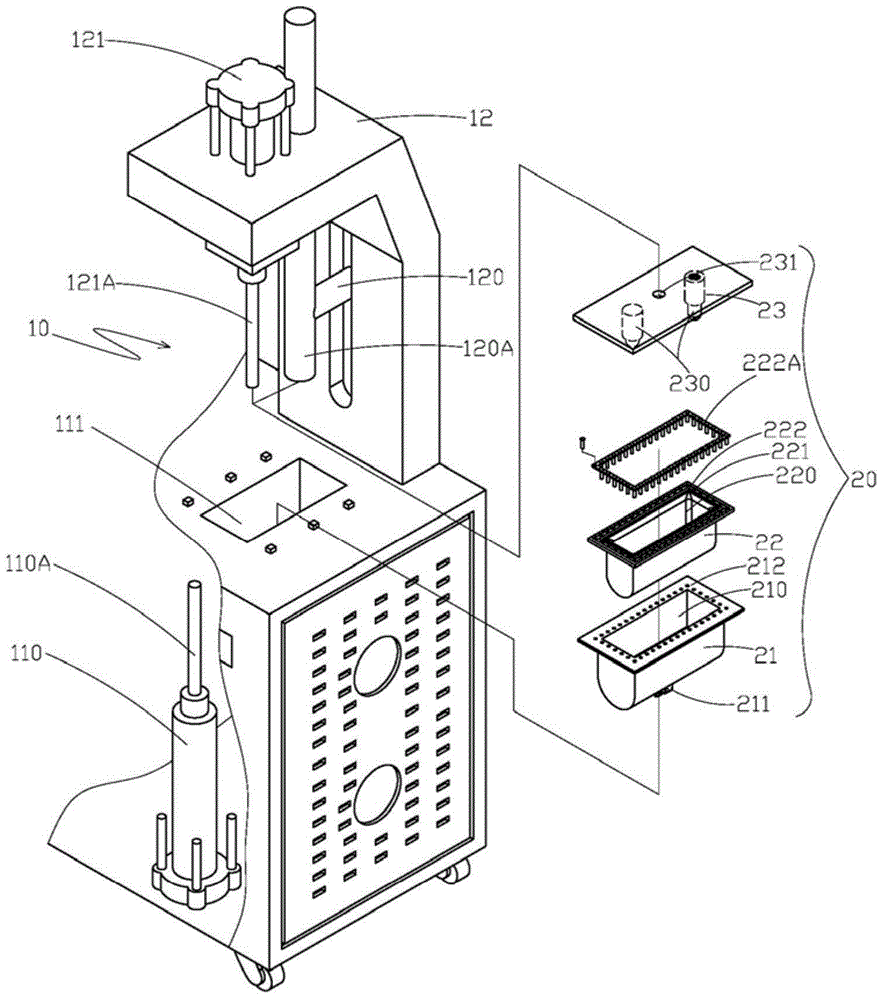

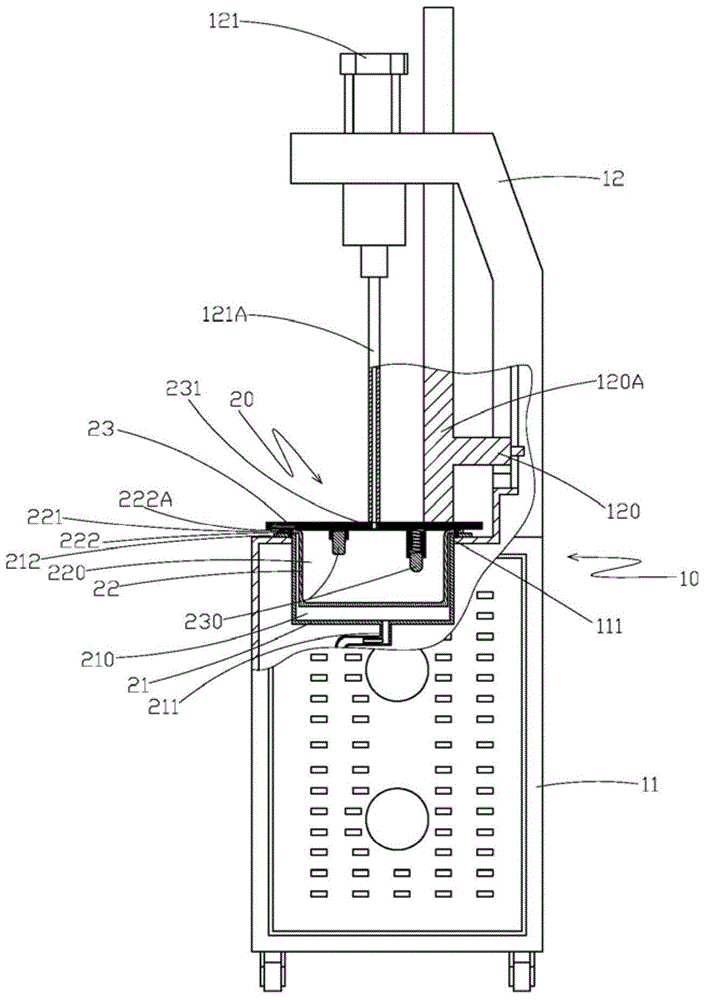

[0045] Please refer to Figures 1 to 3 As shown, it is a reference diagram of the three-dimensional combination, three-dimensional decomposition and side view partial section of the structure of the vacuum sole shoemaking machine of the present invention, which includes:

[0046] A machine body 10, the machine body 10 is provided with a base portion 11 and at least one cantilever portion 12, and the base portion 11 is provided with at least one air pump 110, and the air pump 110 is provided with an air pipe 110A, And the top surface of the base part 11 is provided with at least one accommodating groove 111 relative t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com