Heat balance BOPP film for mold internal heating attaching and manufacturing technology thereof

A production process and heat balance technology, applied in lamination auxiliary operations, synthetic resin layered products, lamination, etc., can solve the problem of limited adhesion strength, poor static electricity export ability of the film, and inconsistency between the film and the container, etc. problem, to achieve the effect of eliminating the cleaning label and adhesive process, exporting strong static electricity, and long-term brand display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

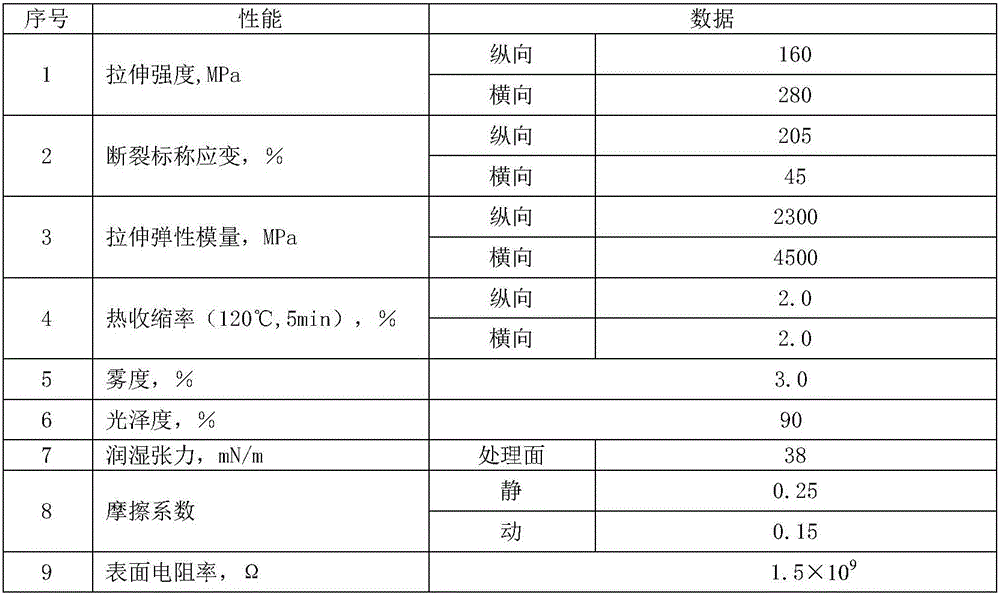

Embodiment 1

[0029] The components of the middle layer are 3wt% stiffening masterbatch and 97wt% homopolypropylene; the components of the inner surface layer are 5wt% anti-adhesion masterbatch, 10wt% polymer alloy type conductive masterbatch and 85wt% homopolypropylene; The components of the outer layer are 5wt% anti-adhesion masterbatch, 10wt% polymer alloy type conductive masterbatch and 85wt% ethylene-propylene-butadiene copolymer.

[0030] According to the following production process for production:

[0031] (1) After drying, the homopolypropylene and stiffening masterbatch of the core layer raw materials are sent to the main extruder to be heated to a molten state, and filtered through a 300-mesh filter; the anti-adhesion masterbatch and polymer alloy of the outer layer raw materials Type conductive masterbatch and ethylene-propylene-butadiene copolymer are heated and melted in an auxiliary extruder, and filtered through a 300-mesh filter; Polypropylene is heated and melted in anoth...

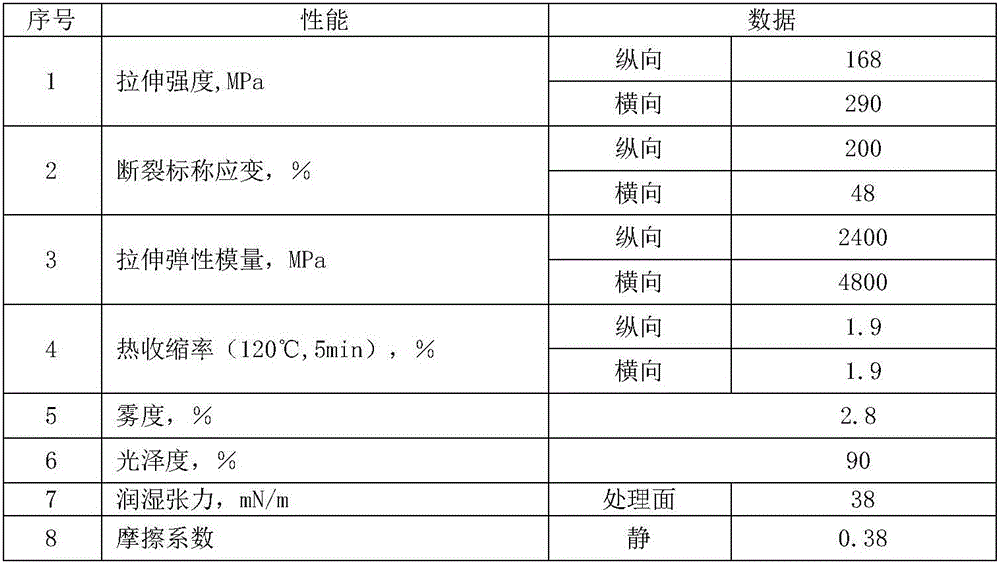

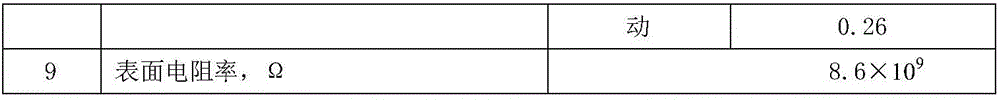

Embodiment 2

[0042] The components of the middle layer are 8wt% stiffening masterbatch and 92wt% homopolypropylene; the components of the inner surface layer are 3wt% anti-adhesion masterbatch, 5wt% polymer alloy type conductive masterbatch and 92wt% homopolypropylene; The composition of the outer layer is 3wt% anti-adhesion masterbatch, 5wt% polymer alloy type conductive masterbatch and 92wt% ethylene-propylene-butadiene copolymer.

[0043] According to the following production process for production:

[0044] (1) After drying, the homopolypropylene and stiffening masterbatch of the core layer raw materials are sent to the main extruder to be heated to a molten state, and filtered through a 300-mesh filter; the anti-adhesion masterbatch and polymer alloy of the outer layer raw materials Type conductive masterbatch and ethylene-propylene-butadiene copolymer are heated and melted in an auxiliary extruder, and filtered through a 300-mesh filter; Polypropylene is heated and melted in another...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com