Low-shrinkage rate bidirectional stretching plastic thin film and preparation method thereof

A biaxially stretched plastic film technology, applied in the field of biaxially stretched plastic film, can solve the problems of reduced production efficiency, insufficient product width, poor economy, etc., and achieve the effect of reducing longitudinal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

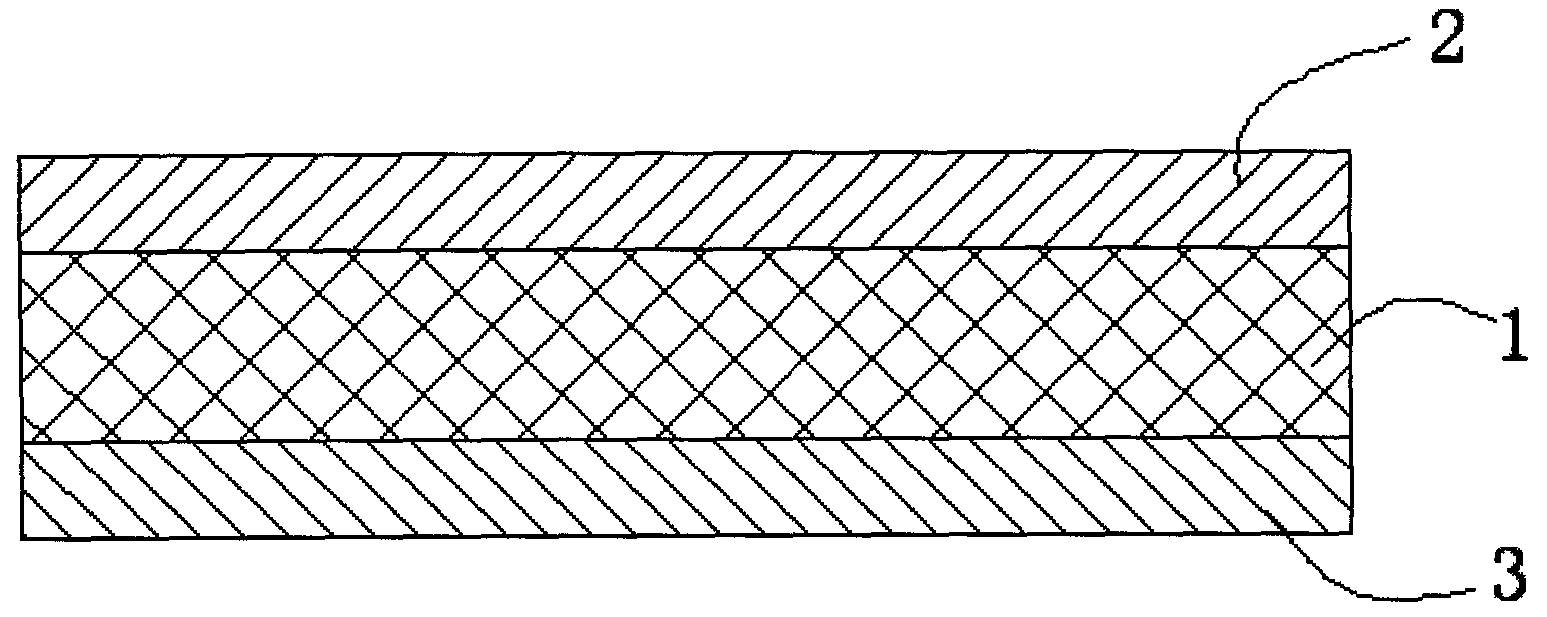

[0021] refer to figure 1 , a low shrinkage biaxially stretched plastic film, comprising a core layer 1, the material of the core layer 1 is polyethylene terephthalate (PET); also includes an upper surface layer 2 and a lower surface layer 3, the said The upper surface layer 2 covers the upper surface of the core layer 1, and the lower surface layer 3 covers the lower surface of the core layer 1;

[0022] The materials of the upper surface layer 2 and the lower surface layer 3 are:

[0023] Contains SiO 2 Amount of 3000ppm polyethylene terephthalate (PET): 60 parts by mass;

[0024] Polyethylene terephthalate (PET): 40 parts by mass.

[0025] The preparation method of the above-mentioned low shrinkage biaxially stretched plastic film comprises the following steps:

[0026] A. According to the ratio of SiO 2 The powder is mixed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com