Tyre for high-strength light rail car and manufacturing technology thereof

A rail car, high-strength technology, applied in the direction of wheels, wheels, vehicle parts, etc. characterized by rail running parts, can solve the problem of limited space under the rail car, reduce the weight of the wheel set, reduce the size of the wheel Effects on quality, increased flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

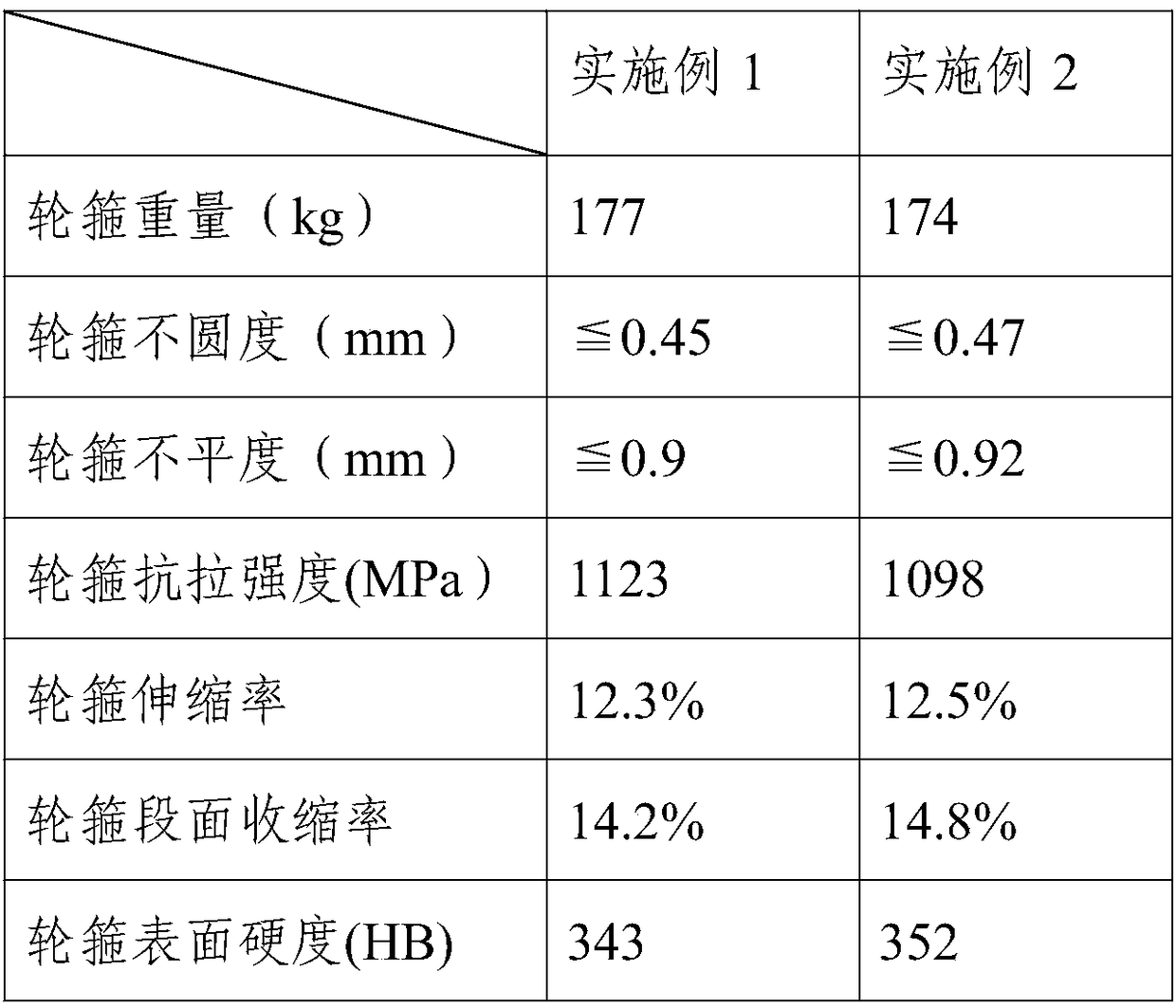

Embodiment 1

[0030] A production process for high-strength light-weight rail car tires, the specific production process is as follows:

[0031] (1) The raw material iron-silicon block, iron-manganese block, pure iron block, iron-magnesium block, iron-aluminum block, iron-chromium block, iron-copper block, iron-nickel block, iron-molybdenum block, iron-vanadium block and iron-titanium block according to certain Mass fraction is weighed;

[0032] (2) Put the weighed pure iron block into the electric furnace for smelting, smelting until the content of carbon element in molten steel is less than 0.82%, the content of sulfur is less than 0.06% and the content of phosphorus is less than 0.04%, to obtain the primary molten steel, by adjusting The carbon content can control and change the strength of the tire. At the same time, the reduction of the sulfur and phosphorus content can prevent the internal space of the tire obtained in the later refining, the strength is small, and it will increase th...

Embodiment 2

[0038] A production process for high-strength light-weight rail car tires, the specific production process is as follows:

[0039] (1) The raw material iron-silicon block, iron-manganese block, pure iron block, iron-magnesium block, iron-aluminum block, iron-chromium block, iron-copper block, iron-nickel block, iron-molybdenum block, iron-vanadium block and iron-titanium block according to certain Mass fraction is weighed;

[0040] (2) Put the weighed pure iron block into the electric furnace for smelting, smelting until the content of carbon element in molten steel is less than 0.82%, the content of sulfur is less than 0.06% and the content of phosphorus is less than 0.04%, to obtain the primary molten steel, by adjusting The carbon content can control and change the strength of the tire. At the same time, the reduction of the sulfur and phosphorus content can prevent the internal space of the tire obtained in the later refining, the strength is small, and it will increase th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com