Hot forming method for high-strength complex material particle board

A technology of thermoforming and particle board, which is applied to wood processing appliances, household components, flat products, etc., and can solve the problems of low qualified rate of composite particle board products, delamination, blockage of steel mesh, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

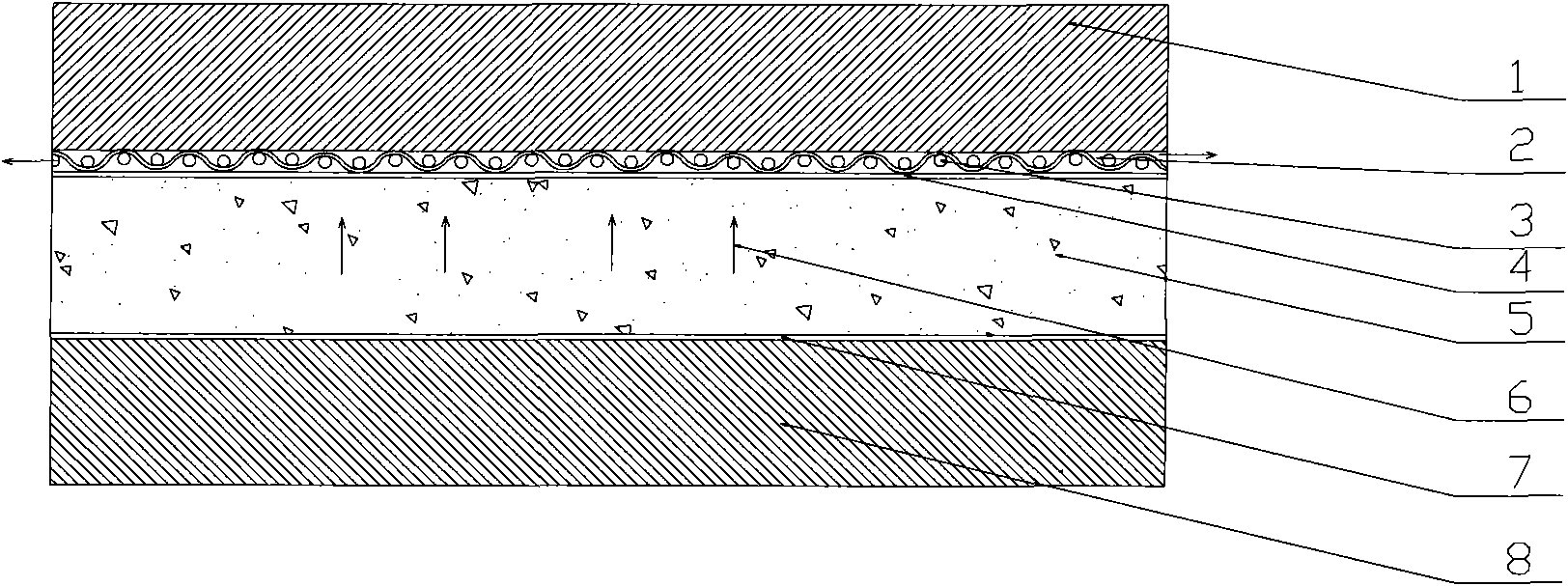

[0067] The format is 1250X1250X18MM (2 layers with green bamboo curtains, the thickness of the 2 layers with green bamboo curtains is 7MM) manufacturing method of high-strength particleboard with green bamboo curtains:

[0068] 1. Production of shaving blank layer 5: crush plant particles such as twig wood and wood waste as raw materials, and the moisture content of the shaving raw material is ≤15%. Calculate the weight of the shavings according to the volume of the produced board (volume of the particle board x0.6=weight, put in weight=weight x1.15, glue mixing 10-12%);

[0069] 2. Selection: 1250X1250 with green bamboo curtain, moisture content ≤ 15%, bamboo yellow surface sprayed with glue;

[0070] The programming time is 2-3 hours in summer and 4-6 hours in winter.

[0071] 3. Manual composite particle board assembly: as Figure 5 As shown, in the lower mold frame 10, the stainless steel plate 9, the lower bamboo curtain with green bamboo as the lower composite material...

Embodiment 2

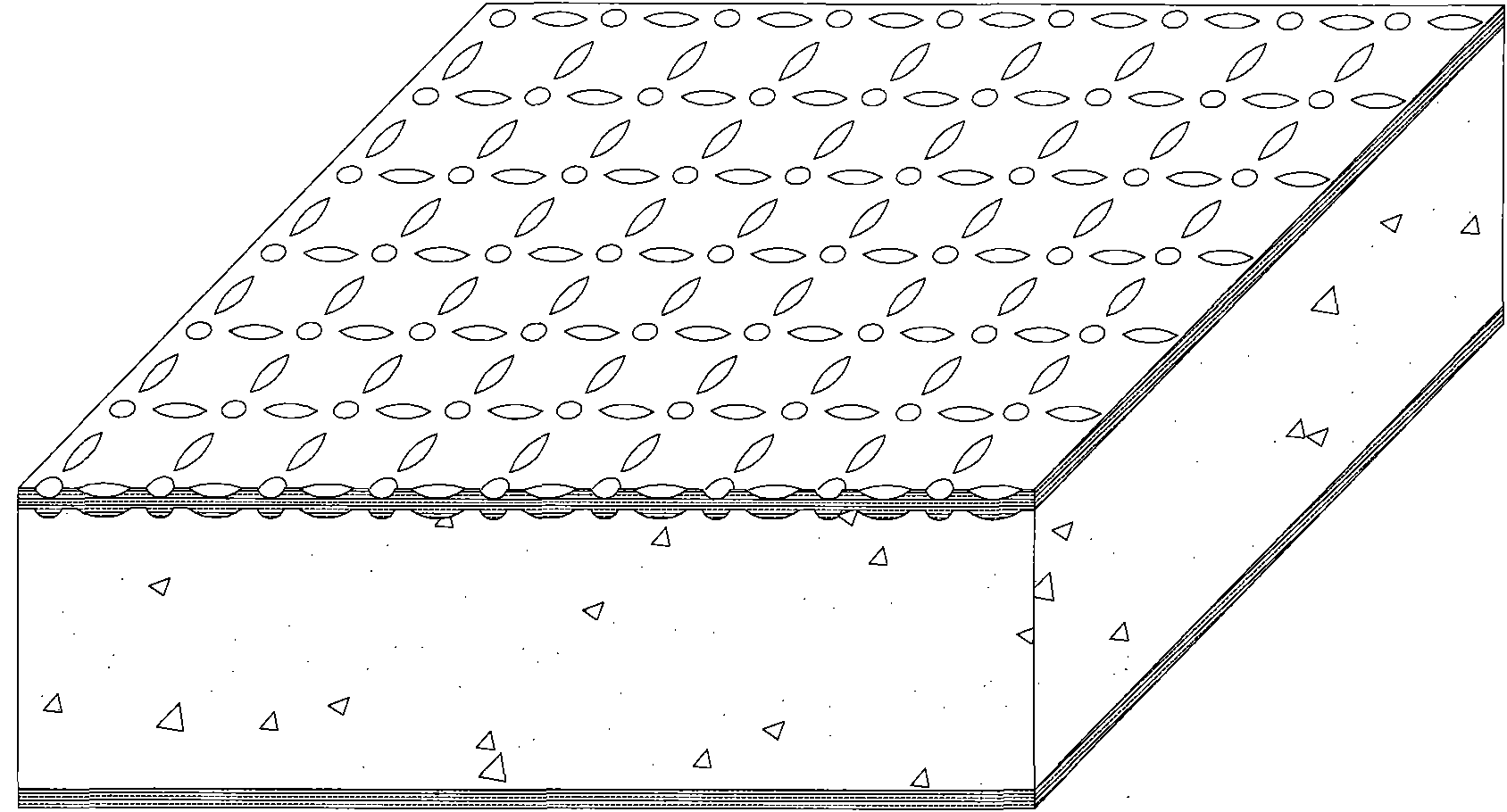

[0079] The manufacturing method of high-strength mat wood particleboard with a format of 1250X1250X14MM (mat wood thickness 3MM):

[0080] 1. Production of shaving blank layer 5: crush plant particles such as twig wood and wood waste as raw materials, and the moisture content of the shaving raw material is ≤15%. Calculate the weight of the shavings according to the volume of the produced board (volume of the particle board x0.6=weight, put in weight=weight x1.15, glue mixing 10-12%);

[0081] 2. Selection: bamboo mat 1250X1250X1.6, moisture content ≤ 15%, bamboo mat impregnated, curing time: 2-3 hours in summer, 4-6 hours in winter.

[0082] Two sheets of veneer 1250X1250X1, moisture content ≤ 15%, one of the veneers is impregnated.

[0083] 3. Manual composite particle board assembly: as Figure 8 As shown, in the lower mold frame 10, the stainless steel plate 9, the impregnated bamboo mat as the lower composite material layer 7, the quantitative glue-mixed shavings are til...

Embodiment 3

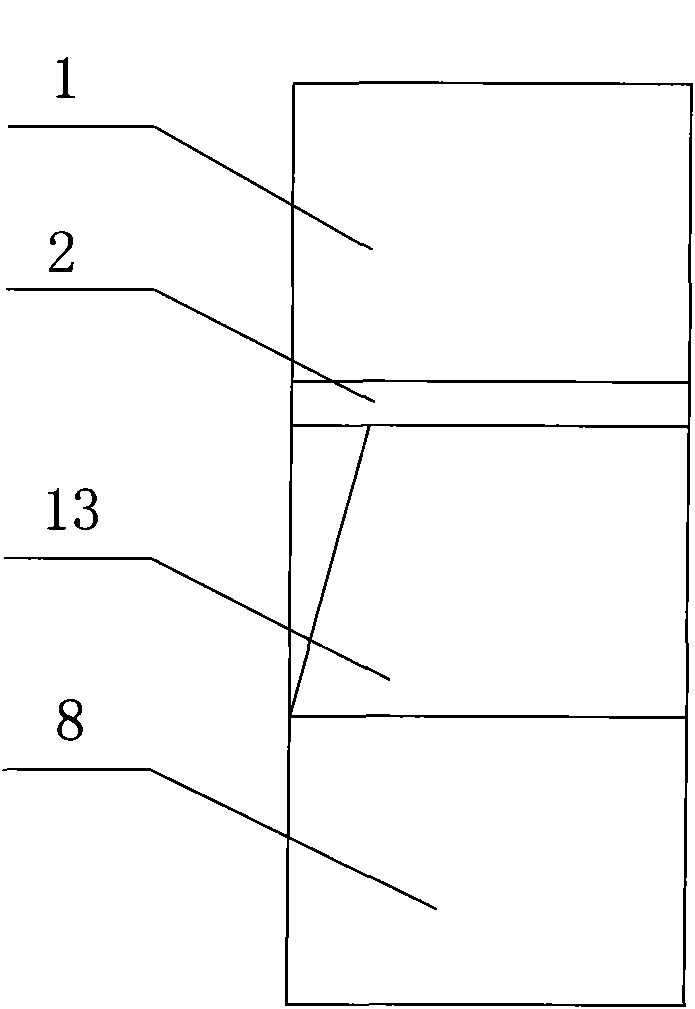

[0091] The format is 1250X1250X10MM (2 layers of veneer thickness 2MM) The manufacturing method of high-strength two-way resin veneer particleboard:

[0092] 1. Production of shavings: Crush twigs, wood waste and other plant particles as raw materials, and the moisture content of the shavings raw materials is ≤ 15%. Calculate the weight of the shavings according to the volume of the produced board (volume of particle board x0.6 = weight, put in weight = weight x 1.15 , mixing glue 10-12%);

[0093] 2. Selection: Two sheets of veneer 1250X1250X1, moisture content ≤ 15%, one of which is glued on both sides, and the other is glued on one side;

[0094] 3. Manually assemble the composite material particle board: 1. Put the stainless steel plate 9 in the lower mold frame 10, 2. Put in the double-sided glued veneer, 3. Put in the quantitative glue-mixed shavings (scraping), 4. Put in Single-sided glued veneer (upper and lower veneer vertical), 5, put into steel mesh 3;

[0095] 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com