Waste fiber non-woven fabric

A waste fiber and non-woven fabric technology, which is applied in non-woven fabrics, textiles, papermaking, synthetic resin layered products, etc., can solve the problems of large proportion of waste fibers, easy falling off of waste fibers, small proportion of waste fibers, etc., to achieve retention performance, damage reduction, drop and waste reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

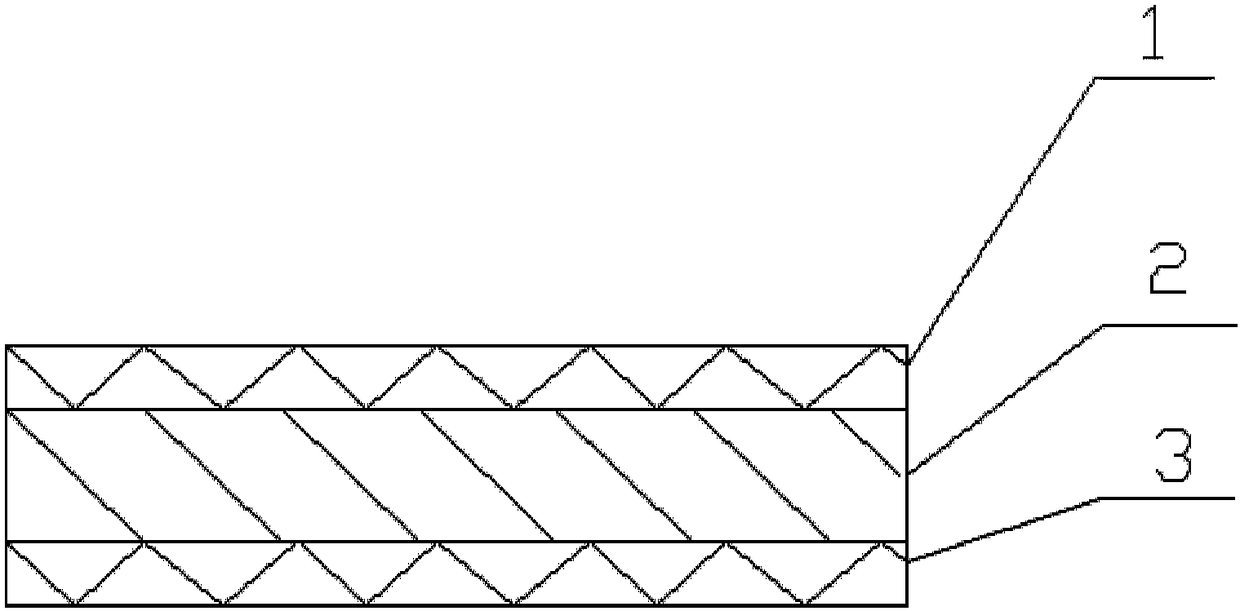

[0021] In an exemplary embodiment of the present invention, a waste fiber nonwoven fabric is provided. figure 1 It is a structural schematic view of the waste fiber nonwoven fabric of the embodiment of the present invention. Such as figure 1 As shown, the utility model waste fiber non-woven fabric comprises an upper layer of new fiber web layer 1, an intermediate layer of waste fiber web layer 2 and a lower layer of new fiber web layer 3, and the above three layers of fiber web layers are reinforced by stitching non-woven methods. , the materials of the upper new fiber web layer 1 and the lower new fiber web layer 3 are filaments, thereby ensuring the reinforcement strength of the upper and lower layers and stitching li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com