Rotor spinning false twister

A false twist disk and rotor spinning technology, applied in the field of rotor spinning false twist disk, can solve the problems of increased yarn friction, limited false twist effect, accumulation of dust or impurities, etc., to reduce broken ends and improve the industry The effect of the upgrade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

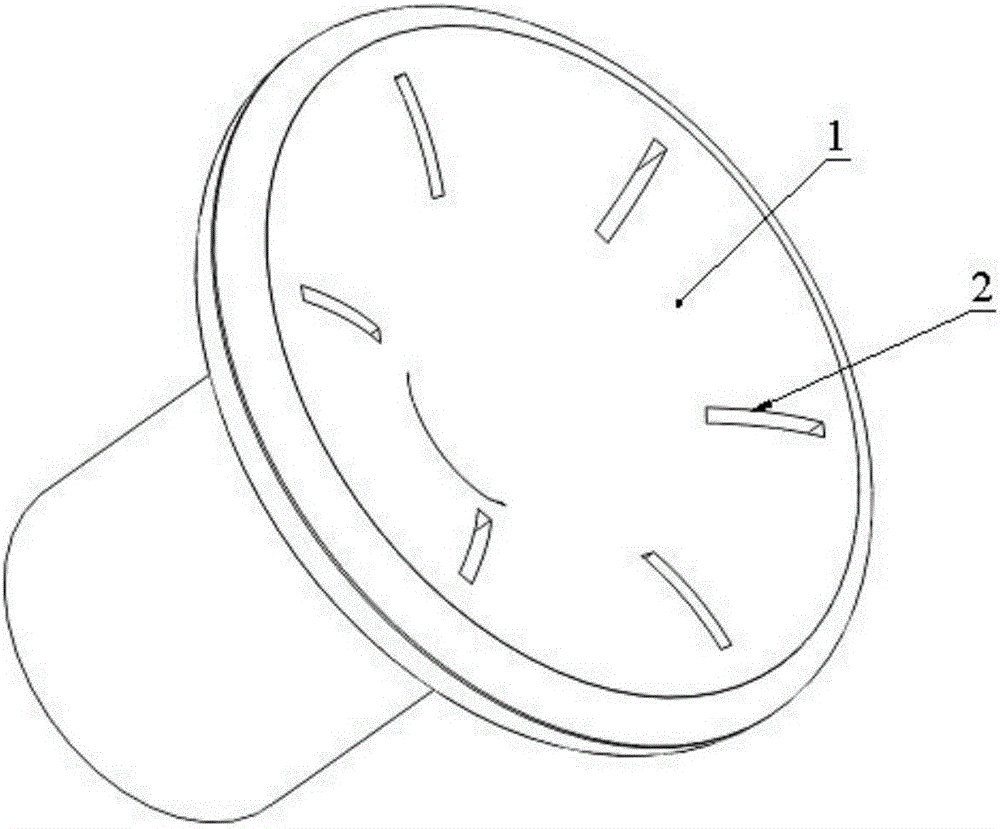

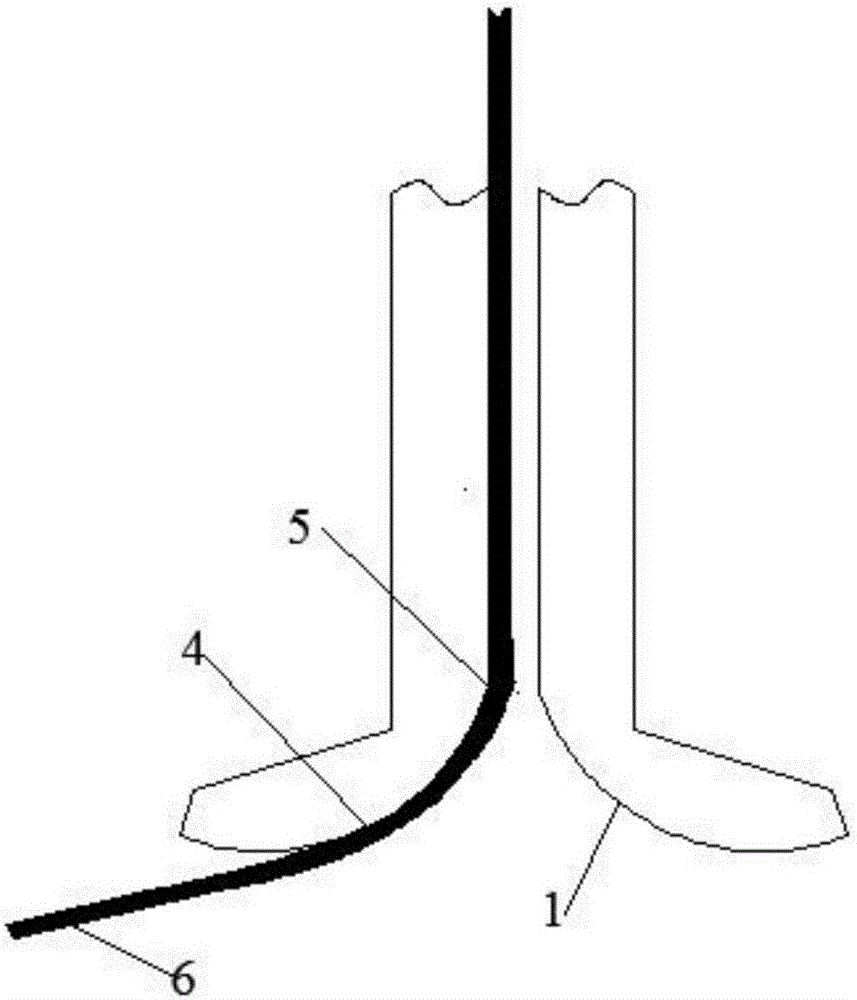

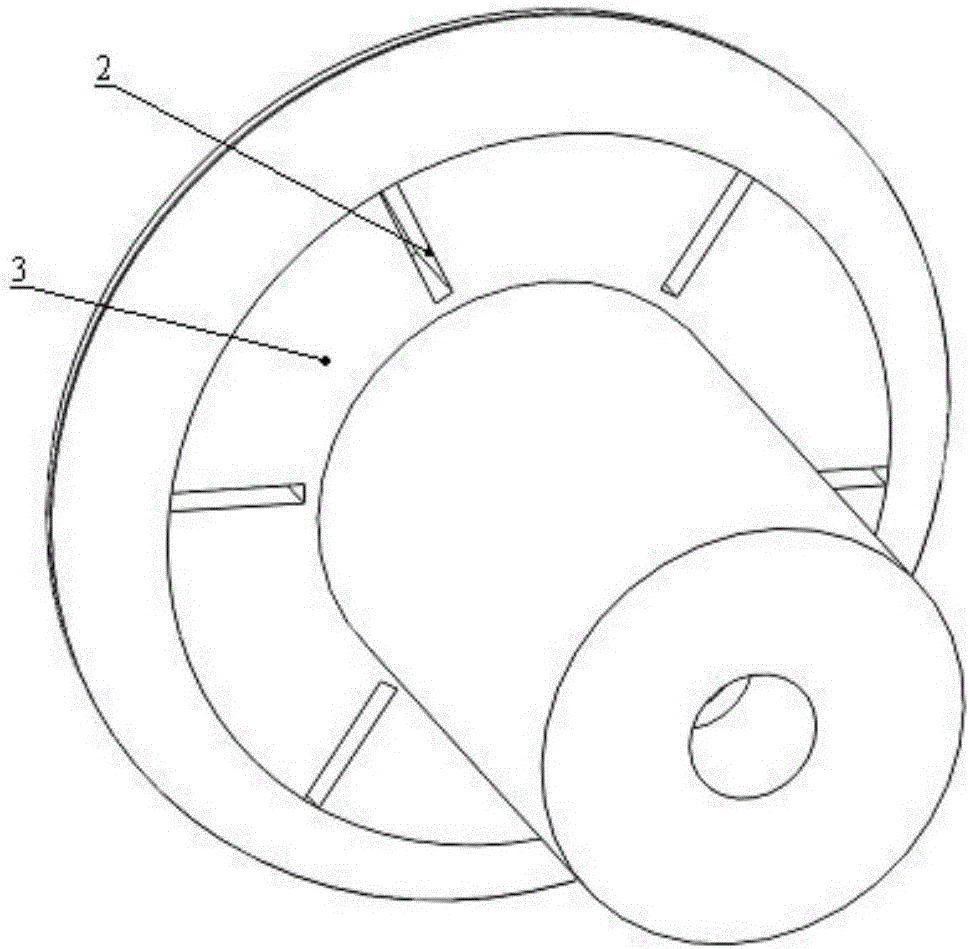

[0028] A false twist disk for rotor spinning, the structure is as follows Figure 1-3 As shown, the arc surface part 1 of the false twist disc body has a narrow slit 2, image 3 The position of the lower bottom surface 3 of the arc surface part of the false twisting disc body is shown in , the narrow slit 2 runs through the upper bottom surface of the arc surface part of the false twisting disc body and the lower bottom surface 3 of the arc surface part of the false twisting disc body, and the cross-sectional area of the narrow slit 2 is 0.11mm 2 . The width of the slit 2 is 0.05 mm, and the length of the slit 2 is 2.2 mm. The slits 2 are distributed in the arc surface part between the initial contact point 4 of the yarn 6 drawn out from the rotor cup and the arc surface of the false twist disc to the connection point 5 of the yarn drawing tube and the arc surface of the false twist disc. A narrow slit 2 is provided along the generatrix direction of the arc surface part 1 ...

Embodiment 2

[0030] A false twist disk for rotor spinning, the arc surface part 1 of the false twist disk body is provided with a narrow slit 2, the narrow slit 2 runs through the upper and lower bottom surfaces 3 of the arc surface part 1 of the false twist disk body, and the cross-sectional area of the narrow slit 2 is 1.5 mm 2 . The width of the slit 2 is 0.3 mm, and the length of the slit 2 is 5 mm. The slits 2 are distributed in the arc surface part between the initial contact point 4 of the yarn 6 drawn out from the rotor cup and the arc surface of the false twist disc to the connection point 5 of the yarn drawing tube and the arc surface of the false twist disc. A narrow slit 2 is provided along the generatrix direction of the arc surface part 1 of the false twist disc body. The number of slits 2 is six. The narrow slit 2 is a waist-shaped slit, and the curved surface 1 of the false twist disc body is made of steel.

Embodiment 3

[0032] A false twist disk for rotor spinning, the arc surface part 1 of the false twist disk body has a narrow slit 2, the narrow slit 2 runs through the upper and lower bottom surfaces 3 of the arc surface part 1 of the false twist disk body, and the cross-sectional area of the narrow slit 2 is 2mm 2 . The width of the slit 2 is 0.5 mm, and the length of the slit 2 is 4 mm. The slits 2 are distributed in the arc surface part between the initial contact point 4 of the yarn 6 drawn out from the rotor cup and the arc surface of the false twist disc to the connection point 5 of the yarn drawing tube and the arc surface of the false twist disc. A narrow slit 2 is provided along the generatrix direction of the arc surface part 1 of the false twist disc body. The number of slits 2 is eight. The narrow slit 2 is a square slit, and the curved surface of the false twist disc body is 1 steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sectional area | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com