Armature wind wheel press mounting device of motor

A press-fitting device and armature technology, which is applied in the manufacture of stator/rotor bodies, etc., can solve the problems of relatively high technical proficiency requirements for workers, the inability to guarantee the overall quality of the motor, and the impact on the working quality of the wind wheel, so as to save operating procedures, The effect of cumbersome installation operation steps and stable assembly quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

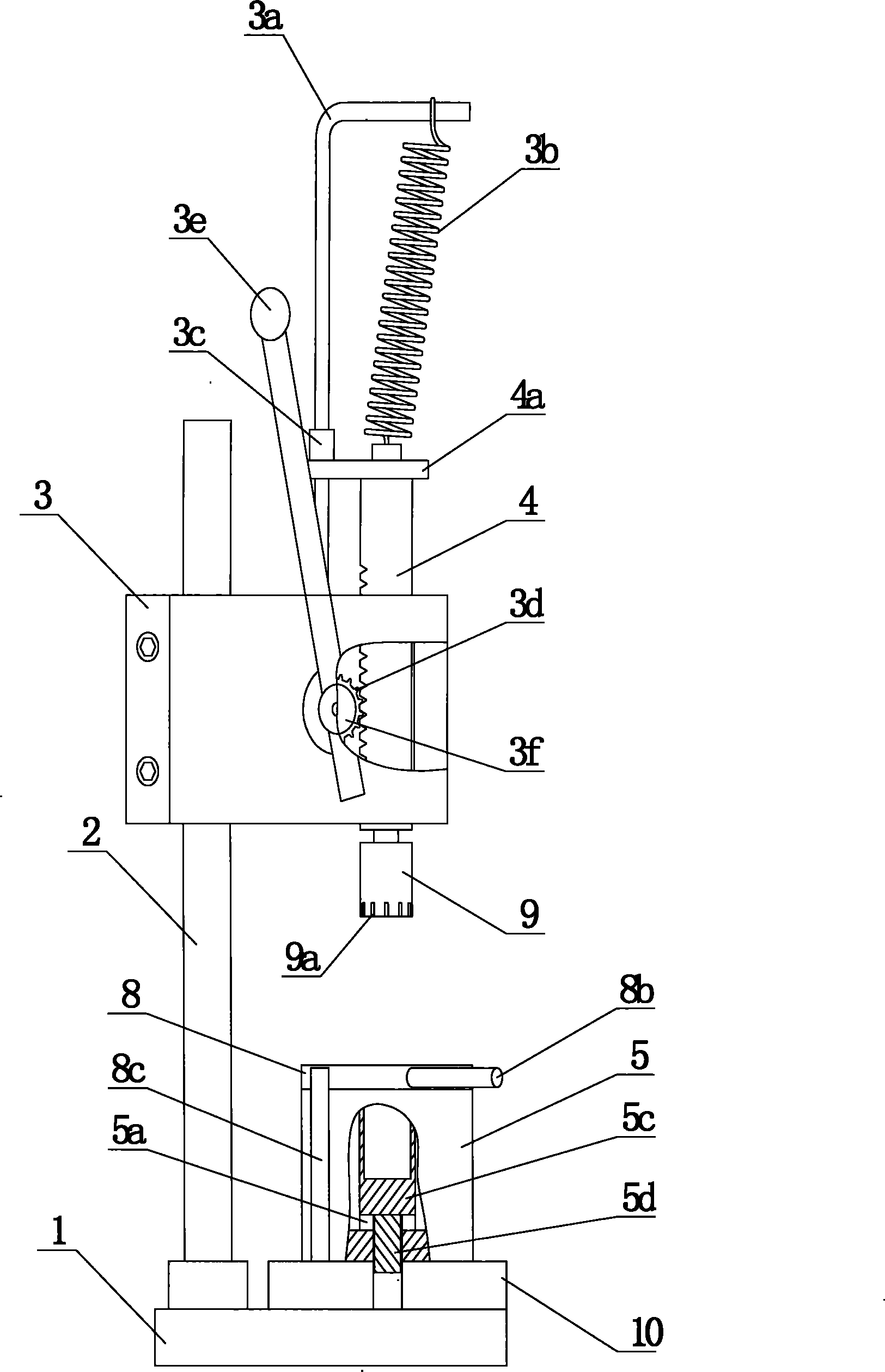

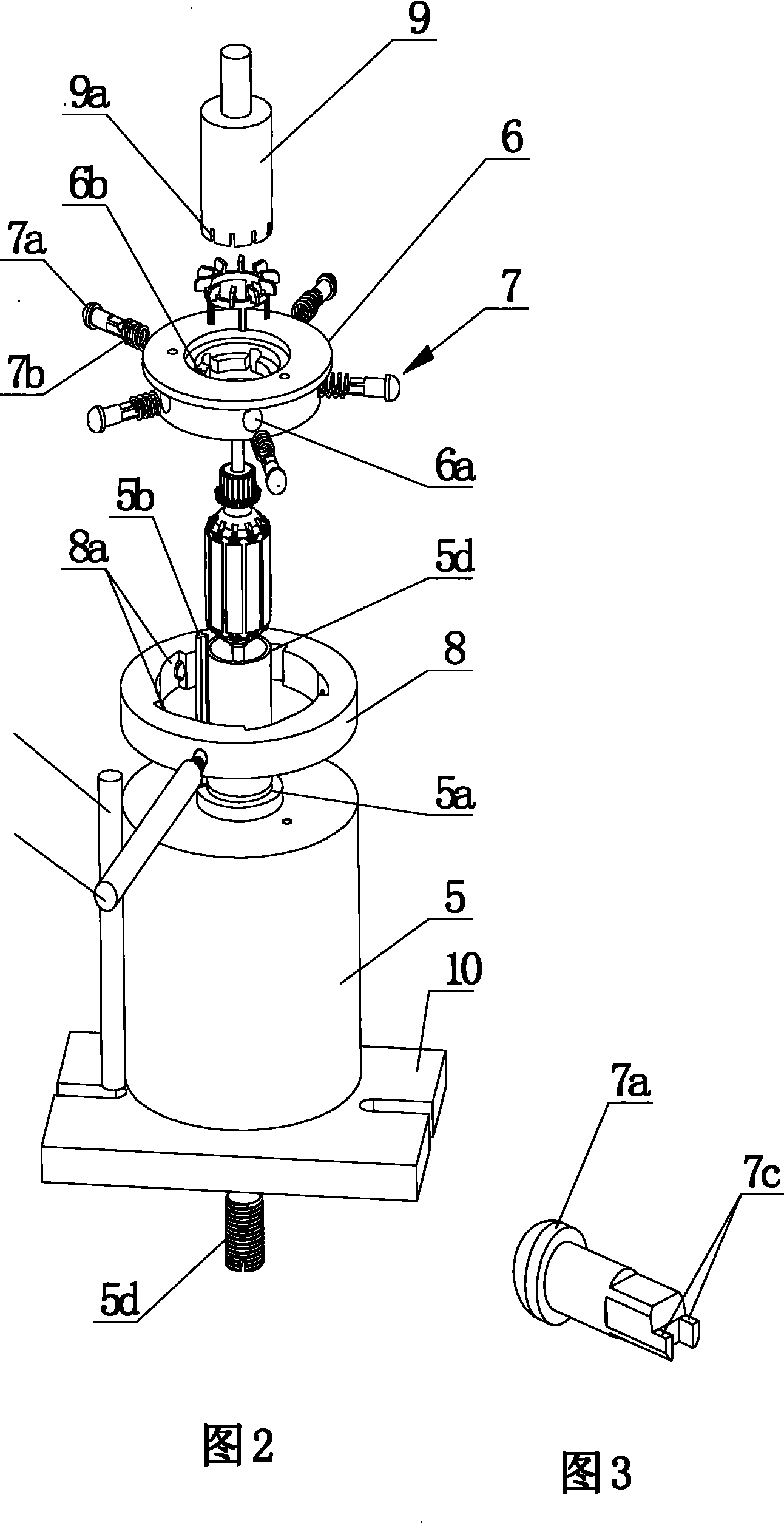

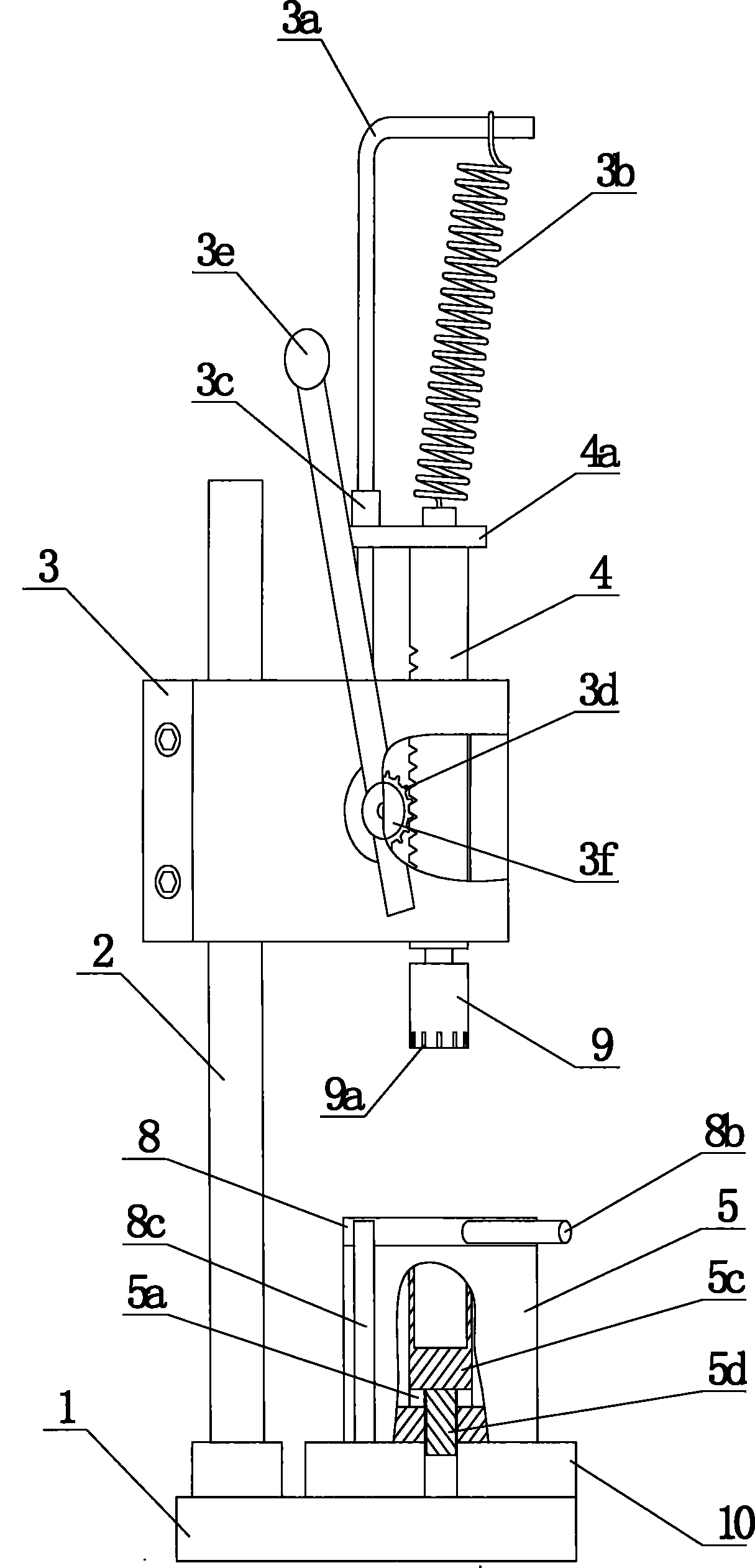

[0016] refer to Figure 1 to Figure 3 As shown, the motor armature wind wheel pressing device of the present invention comprises a base 1, a vertical guide rail 2 is provided on the base 1, an upper die seat 3 is provided on the vertical guide rail 2, and an upper die seat 3 is provided on the upper die seat 3. There is a lower punch 4, and one side of the lower punch 4 is provided with lifting teeth, and a driving gear 3d is arranged in the upper punch seat 3 next to the lifting teeth, and the lifting teeth are meshed with the driving gear 3d, and a handle is provided on the outside of the upper punch seat 3 3e, the handle 3e is fixedly connected with the driving gear 3d through the connecting rod 3f, and the up and down movement of the lower punch 4 can be controlled by the handle 3e; a positioning seat 5 is installed on the base 1, and the positioning seat 5 in this embodiment is fixed on the base plate 10, then the base plate 10 is fixed on the base 1 to form an integral l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com