Diameter-reducing telescopic tube device for braiding machine

A telescopic tube and braiding machine technology, which is applied to braids, textiles and papermaking, etc., can solve the problems of low yield, uneven pitch of variable-diameter telescopic tubes, and unstable diameter deviation, saving raw materials and manpower. , the effect of improving product quality and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

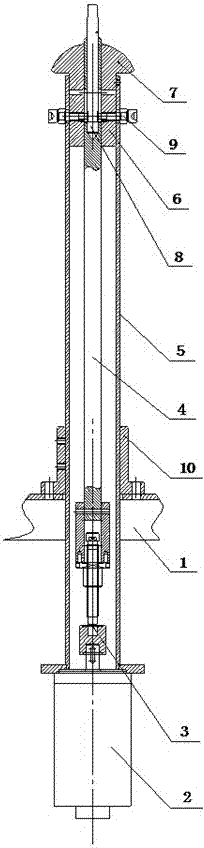

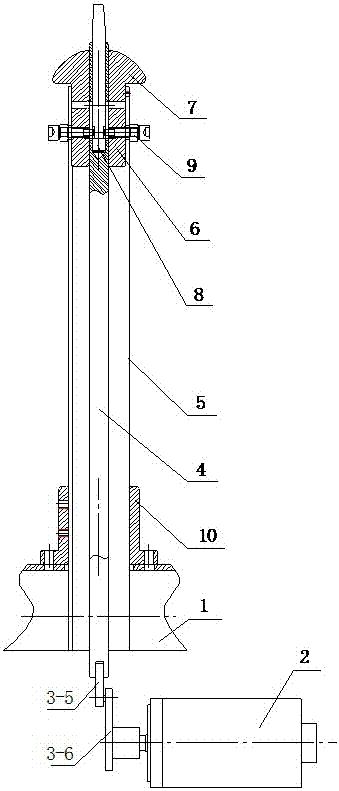

[0020] Embodiment 1: The variable-diameter expansion tube device includes a reciprocating device for moving up and down, a wire passing support positioning device, a core fixing seat 10 and a frame 1; the reciprocating device for moving up and down is connected to the wire passing support and positioning device; the wire passing support positioning device The lower end of the core tube 5 passes through the core fixing base 10 and the frame 1, and is connected with the frame 1 through the core fixing base 10.

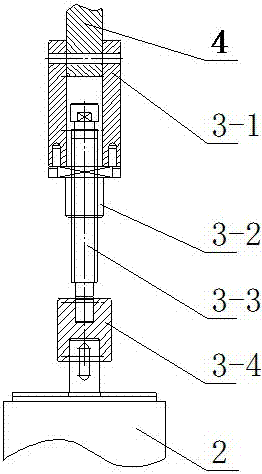

[0021] The reciprocating device for moving up and down includes a motor 2 , a moving rod lifter 3 and a moving rod 4 ; the motor 2 is connected with the moving rod 4 through the moving rod lifter 3 .

[0022] The upper end of the moving rod 4 is arc-shaped, has a blind hole in the center, and has a chute on the upper side, and the chute communicates with the blind hole; the upper end of the moving rod 4 passes through the core sleeve 6 and the wire-passing convex cap 7; t...

Embodiment 2

[0028] Embodiment 2: or described moving rod lifter 3 comprises: connecting rod 3-5 and eccentric wheel 3-6, and one end of connecting rod 3-5 is connected with moving rod 4, and the other end of connecting rod 3-5 is connected with eccentric Rounds 3-6 connect. Or the eccentric wheel 3-6 is a cam, which is directly slidably connected with the bottom end of the moving rod. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com