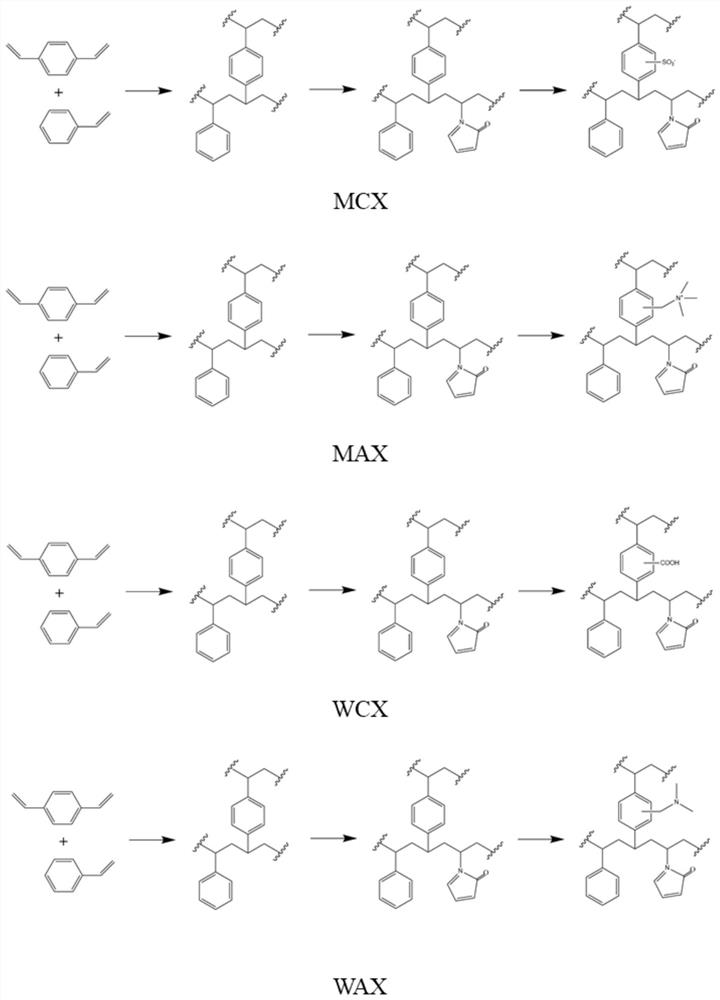

Solid phase extraction material and its preparation method and application

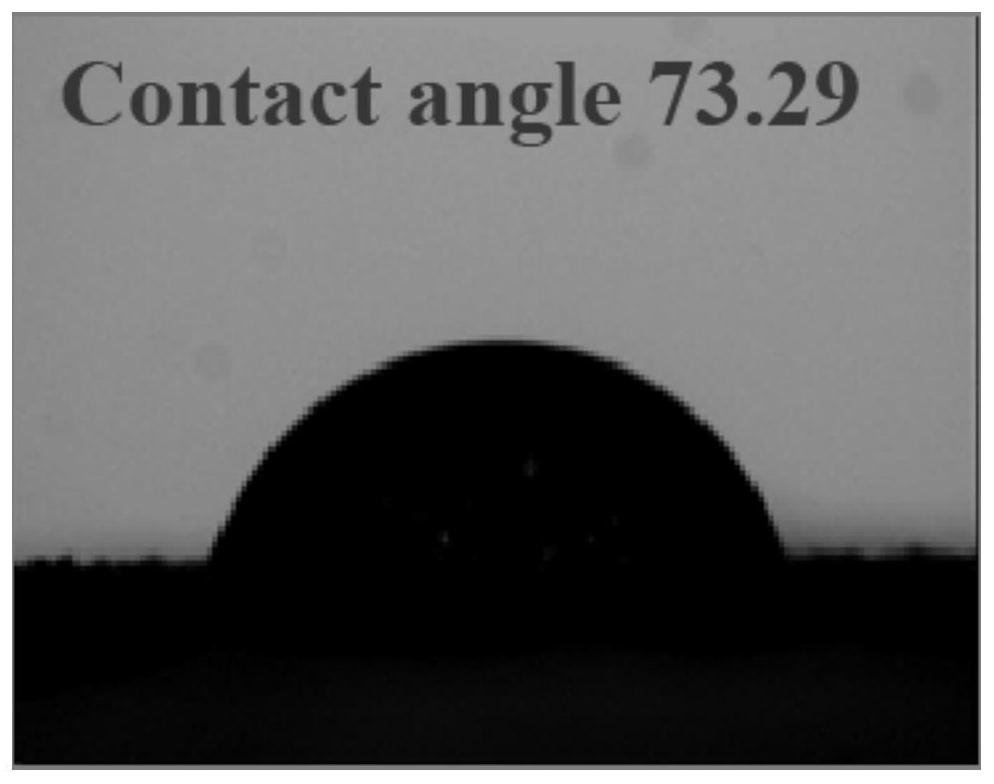

A solid-phase extraction material and reaction technology, which is applied in chemical instruments and methods, other chemical processes, and the improvement of process efficiency, can solve problems such as uncontrollable proportions, and achieve good hydrophilicity, good hydrophilicity, and economic benefits. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

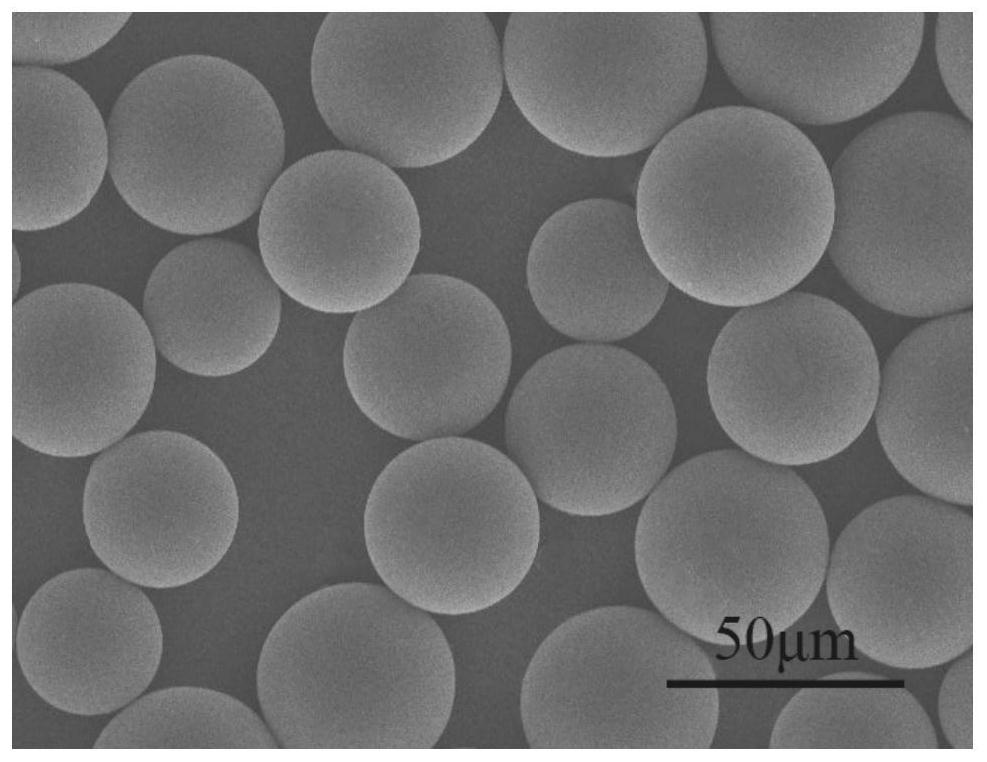

[0080] (1) Preparation of monodisperse seed microspheres: Mix 15 mL of ethanol and 15 mL of water as the water phase, add 0.4 g of dispersant polyvinylpyrrolidone and 0.1 g of initiator benzoyl peroxide into the water phase, and stir at 60 °C for 30 Minutes until completely dissolved; mix 8g styrene and 2g divinylbenzene as the oil phase and add it dropwise to the aqueous solution. After mixing evenly, gradually increase the temperature to 75°C at a rate of 3°C every 10 minutes, and keep the stirring rate at 450~500rpm After reacting for 4 hours, monodisperse seed microspheres with a particle size of 5-10 µm were obtained;

[0081] Add 0.5g dispersant polyvinylpyrrolidone, 0.375g emulsifier sodium lauryl sulfate, 2g above-mentioned monodisperse seed microspheres, 10g porogen toluene, 10g swelling agent dimethyl phthalate in 100mL aqueous solution, Emulsion A was prepared through 200W ultrasonic enhanced dispersion;

[0082] (2) Prepare white balls with uniform particle size: 10...

Embodiment 2

[0090] Select neutral substances at pH=7: nortriptyline (pKa=9.7), amitriptyline (pKa=9.4), triclosan (pKa=8.1); and acidic substances: buclo Fen (pKa=4.9), bezafibrate (pKa=3.6), and indomethacin (pKa=4.5) were selected as the selected substances, and the strong cation exchange solid phase extraction material prepared in Example 1 was selected: MAX.

[0091] (1) Fill 500mg of solid-phase extraction material into a 6mL solid-phase extraction column with sieve plates at both ends, weigh appropriate amount of the above-mentioned drugs, dissolve them in methanol to make a 1g / L standard stock solution, and draw appropriate amount of standard stock solution to prepare Prepare a mixed standard solution of 1mg / L, and at the same time make a mixed internal standard solution of 1mg / L.

[0092] (2) After activating with 5mL of methanol and cleaning the solid phase extraction material with 5mL of water, pass through the solid phase extraction column, and the column flow rate is controlle...

Embodiment 3

[0096] Select neutral substances under the condition of pH=7: acetaminophen (pKa=9.4), triclosan (pKa=8.14), amphoteric substances: ofloxacin (pKa=5.97, 9.28) and Alkaline substances: clarithromycin (pKa=9.0), erythromycin (pKa=8.9), omeprene (pKa=7.11) are selected as the selected substances, and the strong anion exchange solid phase prepared in Example 1 is selected Extraction material: MCX.

[0097] (1) Fill 500mg of solid-phase extraction material into a 6mL solid-phase extraction column with sieve plates at both ends, weigh appropriate amount of the above-mentioned drugs, dissolve them in methanol to make a 1g / L standard stock solution, and draw appropriate amount of standard stock solution to prepare Prepare a mixed standard solution of 1mg / L, and at the same time make a mixed internal standard solution of 1mg / L.

[0098] (2) After activating with 5mL of methanol and cleaning the solid phase extraction material with 5mL of water, pass through the solid phase extraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com