Anti-silting cover plate, anti-silting system and construction method covered by crushed stone bed of immersed tube tunnel

A technology of immersed tube tunnel and construction method, which is applied in the direction of basic structure engineering, artificial island, water conservancy engineering, etc., and can solve problems such as exceeding the standard, cracking of pipe sections, and affecting the force transmission effect of the foundation bed structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

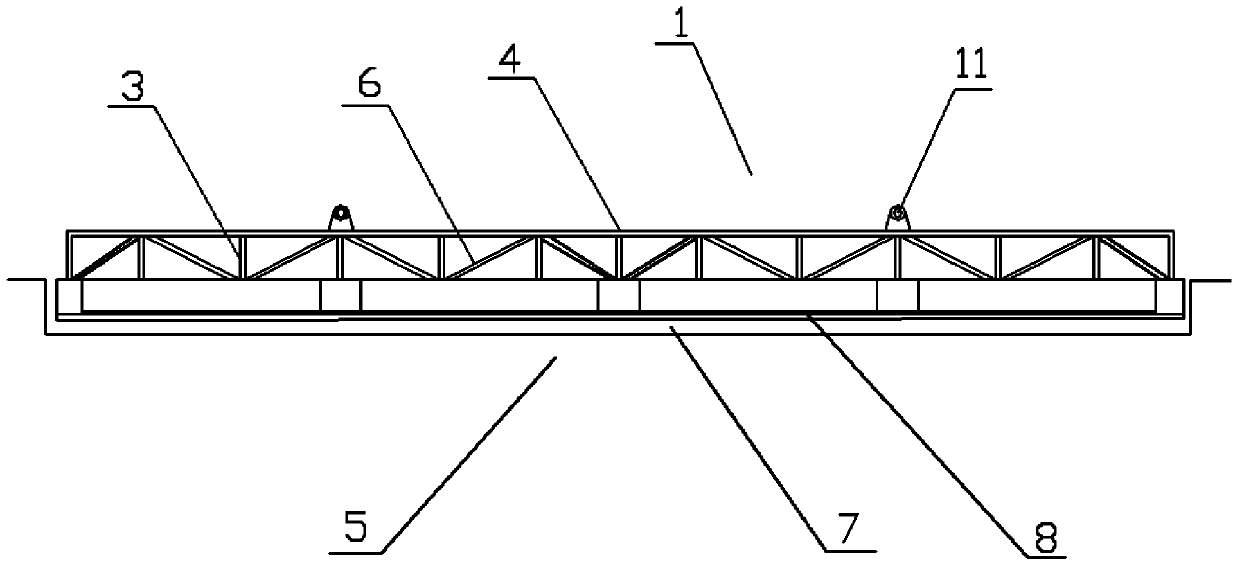

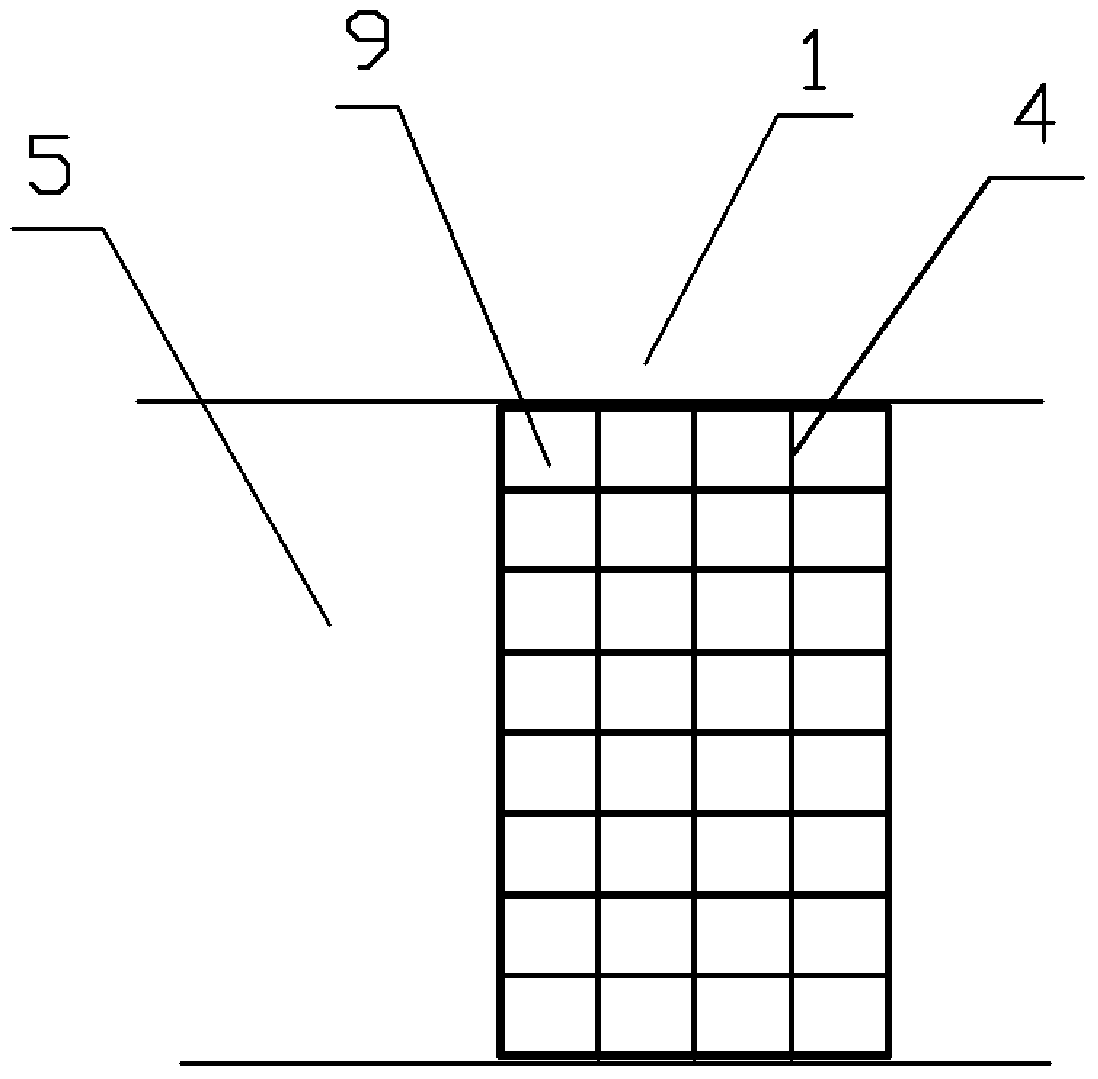

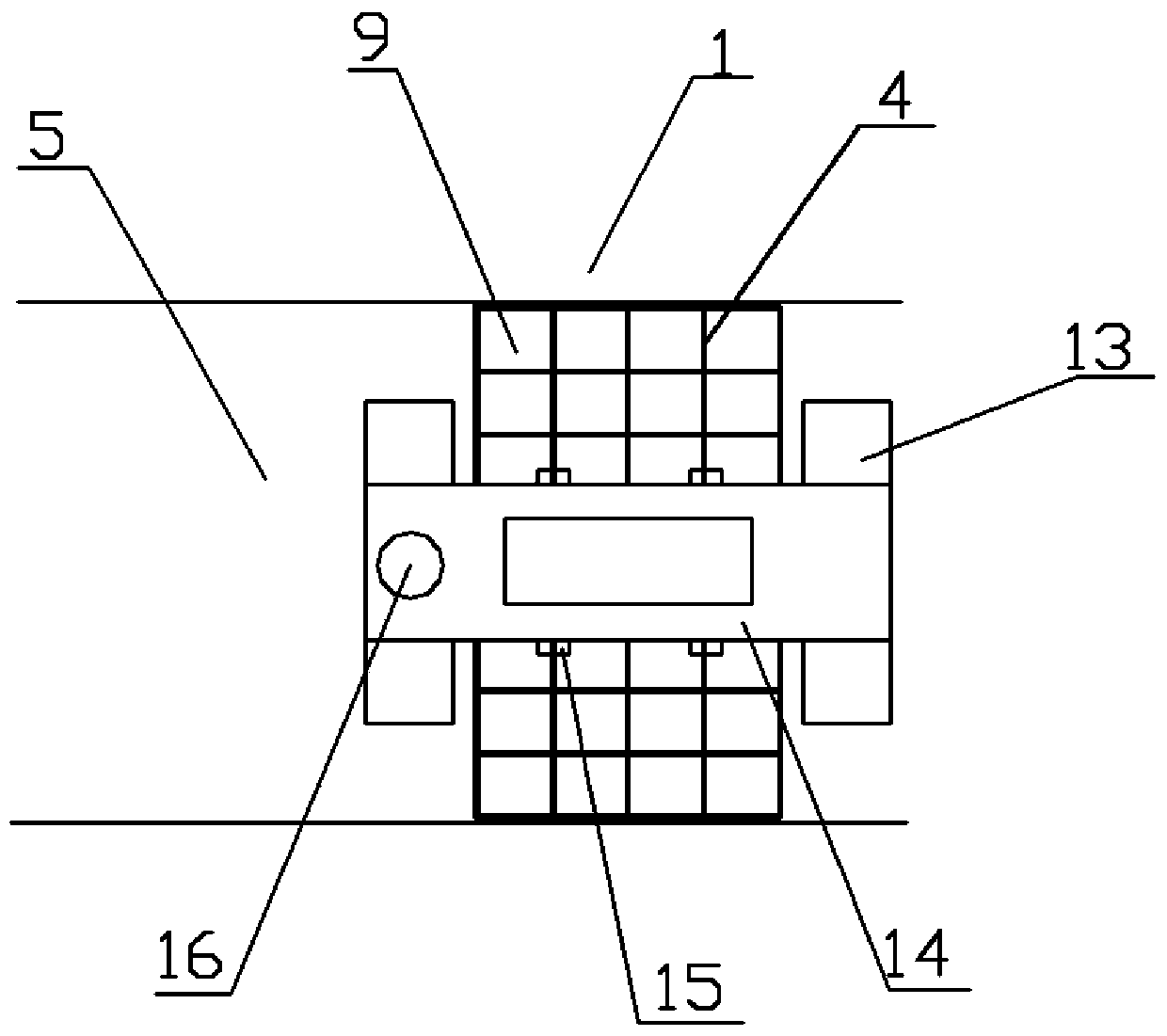

[0030] Such as figure 1 and figure 2 As shown, the foundation leveling width of the crushed stone bed 5 is 42m, the thickness is 1.3m, and it is divided into 7 berths for leveling in the longitudinal direction. According to the segmented length of the subgrade bed 5 leveled, the planar size of the crushed stone subgrade bed covered anti-silting cover plate of the immersed tube tunnel of the present invention is 41m×24.3m, and 7 pieces are produced in total. The cover plate 1 includes a frame, and the frame includes longitudinal beams 3 and cross beams 4. The longitudinal beams 3 and the cross beams 4 are all box structures of steel structure. A plurality of connecting beams 6 are arranged between the longitudinal beams 3, and vertical and horizontal connecting braces 7 are arranged under the whole frame. A steel plate pavement 8 is arranged on the steel plate pavement 8, and a ballast water tank 9 of 4.925m×5.875m can be filled with water and discharged on the steel plate pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com