Outer rotor permanent magnetic synchronous motor

A technology of permanent magnet synchronous motor and external rotor, which is applied in the direction of synchronous motor with stationary armature and rotating magnet, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., which can solve the time-consuming and installation process of motor cumbersome and other problems, to achieve the effect of improving processing efficiency, simple structure and high running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

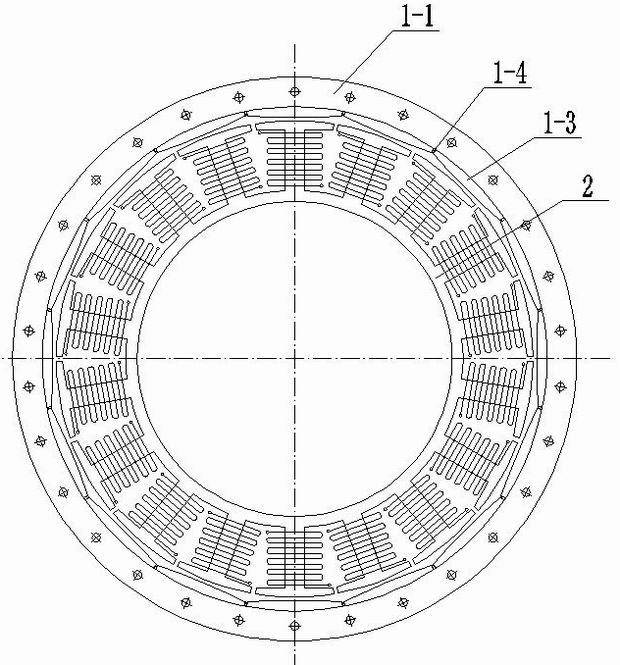

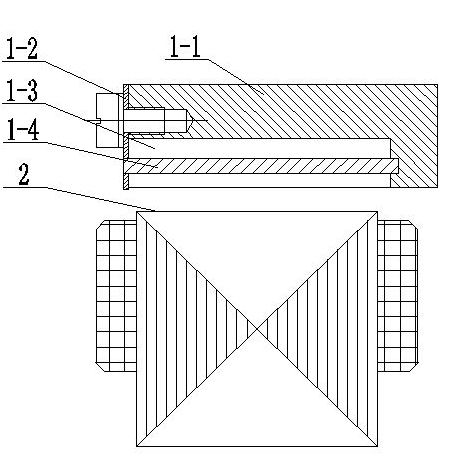

[0011] Specific implementation mode one: the following combination Figure 1 to Figure 4 Describe this embodiment, this embodiment comprises stator 2 and rotor, and it adopts the structure that stator 2 is inside, and rotor is outside, and the outer ring surface of described stator 2 and the inner ring surface of rotor are air gaps, and rotor is formed by rotor yoke 1-1, composed of rotor pressing plate 1-2, permanent magnet 1-3 and key 1-4, rotor yoke 1-1 and rotor pressing plate 1-2 are fixed together to form an inner ring surface with a groove, the groove A plurality of keys 1-4 arranged in the axial direction are equally divided into a plurality of accommodating spaces, and a permanent magnet 1-3 is respectively embedded in each accommodating space.

[0012] In this embodiment, the permanent magnets 1-3 are embedded in multiple accommodating spaces formed by the keys 1-4, which can improve the inaccurate bonding and positioning of the permanent magnets 1-3 and the insuffic...

specific Embodiment approach 2

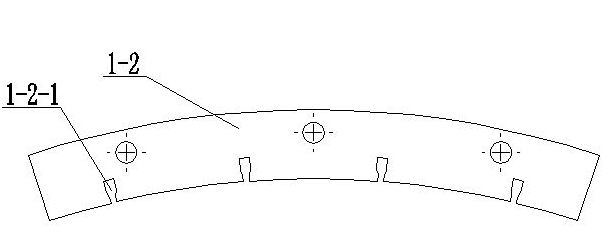

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a plurality of trapezoidal grooves 1-2-1 are provided on the inner ring side of the rotor pressure plate 1-2, and each trapezoidal groove 1-2-1 Secure one end of a key 1-4. Other components and connections are the same as those in Embodiment 1.

[0015] The function of key 1-4 is to separate the placement space of multiple permanent magnets 1-3, and the setting of trapezoidal groove 1-2-1 is to ensure that key 1-4 will not move in the radial direction, better Secure the keys 1-4, thereby securing the permanent magnets 1-3.

specific Embodiment approach 3

[0016] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the rotor pressing plate 1-2 is integrated or spliced. Other compositions and connections are the same as those in the first or second embodiment.

[0017] The rotor press plate 1-2 of the one-piece structure has higher processing and installation accuracy, but when the outer diameter of the motor is larger, the outer diameter of the rotor press plate 1-2 will also be larger, which makes it more difficult to process and will result in more machining. waste, so it is suitable for occasions where the outer diameter of the motor is small; the rotor pressure plate 1-2 of the spliced structure is formed by splicing multiple fan-shaped plates to form a ring. Compared with the integrated structure, the processing and installation accuracy is slightly lower, but the processing Easy, less processing waste, suitable for occasions with large motor outer diameters.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com