Shell stamping device for machining motor

A technology of punching device and casing, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low punching efficiency, inability to realize efficient punching operation, etc., and achieve the effect of improving punching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

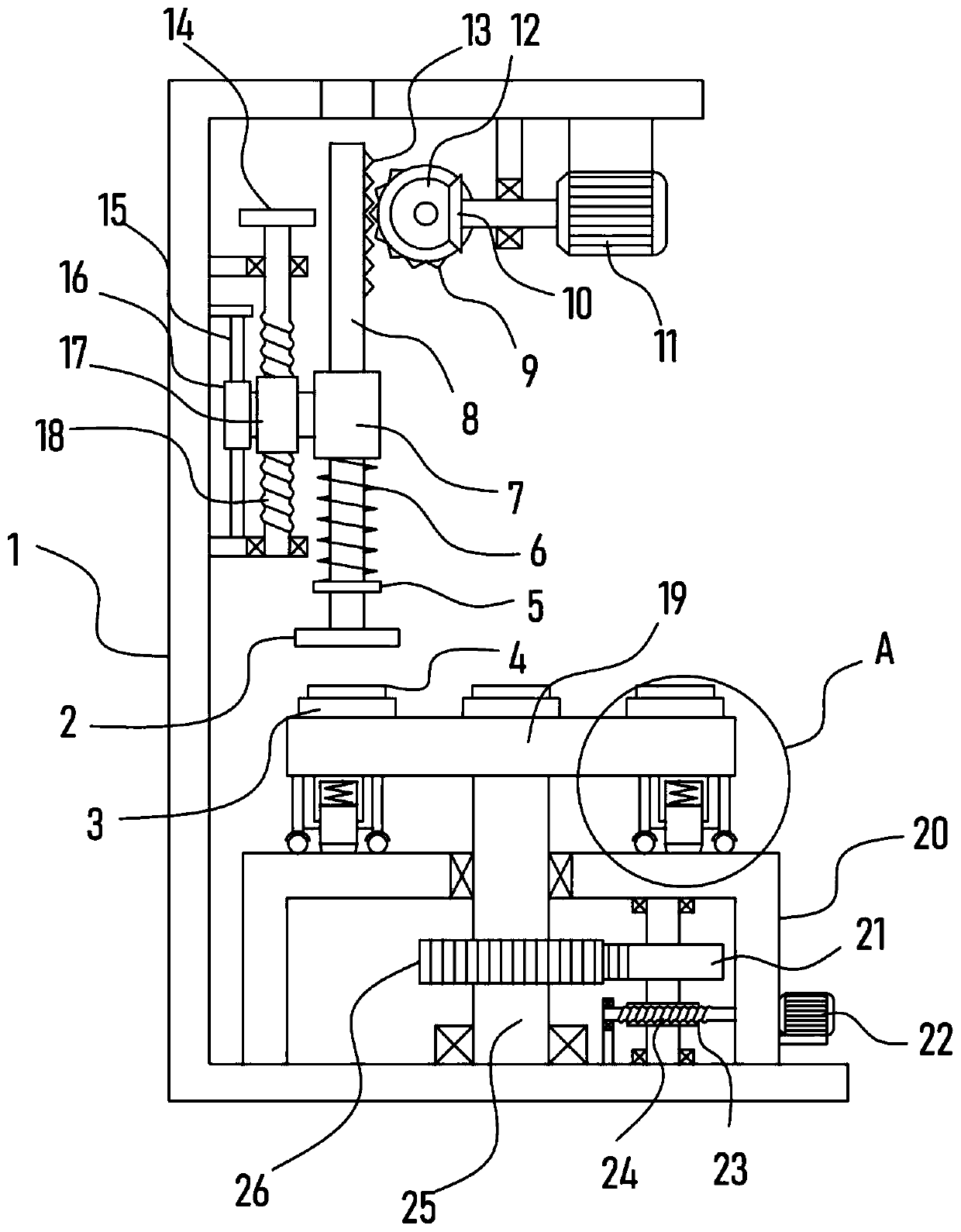

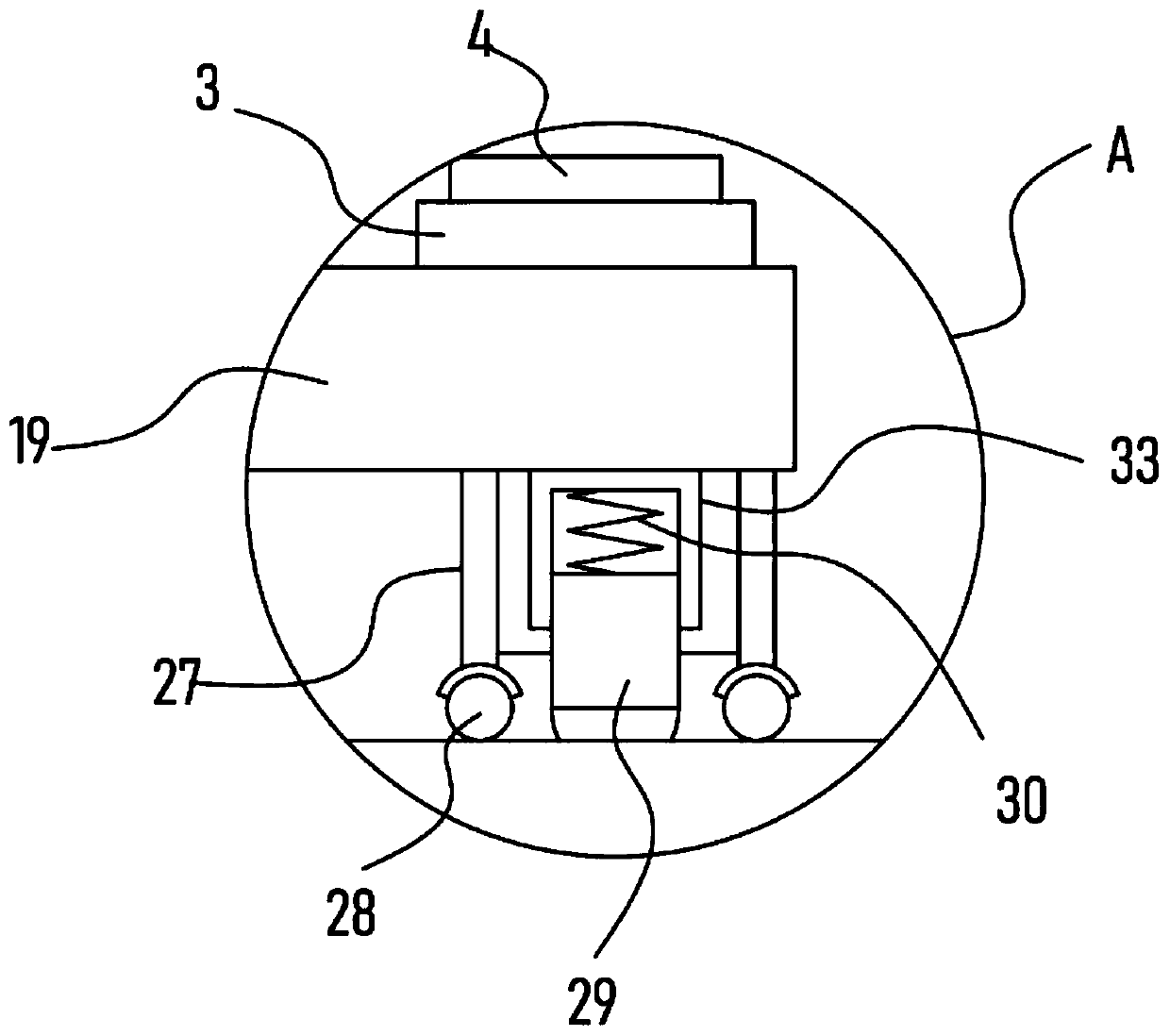

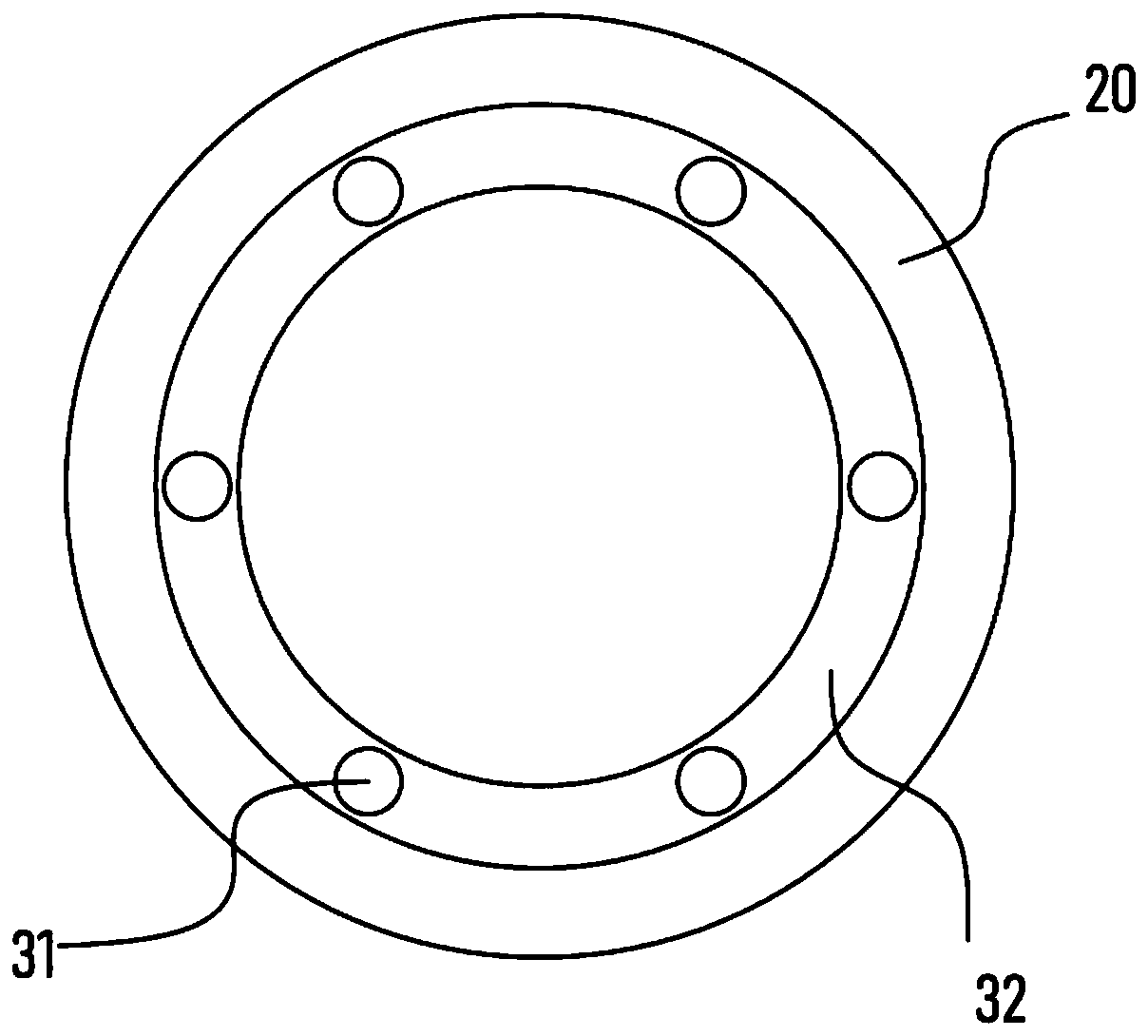

[0025] see Figure 1-4 , a shell stamping device for motor processing, comprising a support frame 1, a fixed frame 20 is fixed on the support frame 1, a motor II22 is fixed on the side wall of the fixed frame 20, and a vertically arranged steering shaft is rotatably mounted on the fixed frame 20 25. The upper end of the steering shaft 25 is vertically fixed with a turntable 19, and the fixed frame 20 is provided with a rotating mechanism for driving the steering shaft 25 to rotate step by step. The turntable 19 is uniformly fixed with several support blocks 3 in the upper direction. A lower mold 4 is fixedly installed on the support block 3, an elastic positioning mechanism is arranged between the turntable 19 and the fixed frame 20, a motor I11 is fixed on the support frame 1, and a vertical lifting mechanism is driven and connected to the motor I11. The vertical lifting mechanism is connected with an upper mold 2 intermittently corresponding to the lower mold 4, and the supp...

Embodiment 2

[0031] On the basis of Embodiment 1, in addition, the rotating mechanism of this device comprises the steering gear 26 that is sheathed and fixed on the steering shaft 25, and the incomplete gear II21 that is intermittently meshed with the steering gear 26 is installed on the support frame 1 to rotate. The mechanism also includes a worm wheel 23 coaxially fixed with the incomplete gear II21, and a worm screw 24 meshed with the output shaft of the motor II22 through a coupling is connected to the worm wheel 23.

[0032] Through the above settings, the motor II22 is used to drive the worm 24 to rotate, and the worm 24 drives the incomplete gear II21 to rotate through the worm wheel 23 meshed with it. At this time, the incomplete gear II21 alternately meshes with the steering gear 26 to realize the cycle of the steering gear 26. Permanent rotation, that is, the lower mold 4 corresponds to the upper mold 2 one by one and realizes the stamping operation, which greatly improves the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com