Boring device for automobile motor processing

A technology for automobiles and double-axis motors, applied in positioning devices, feeding devices, metal processing equipment, etc., can solve the problems of end cover clamping stability and low drilling efficiency, and achieve stable and accurate drilling process and environmentally friendly drilling The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

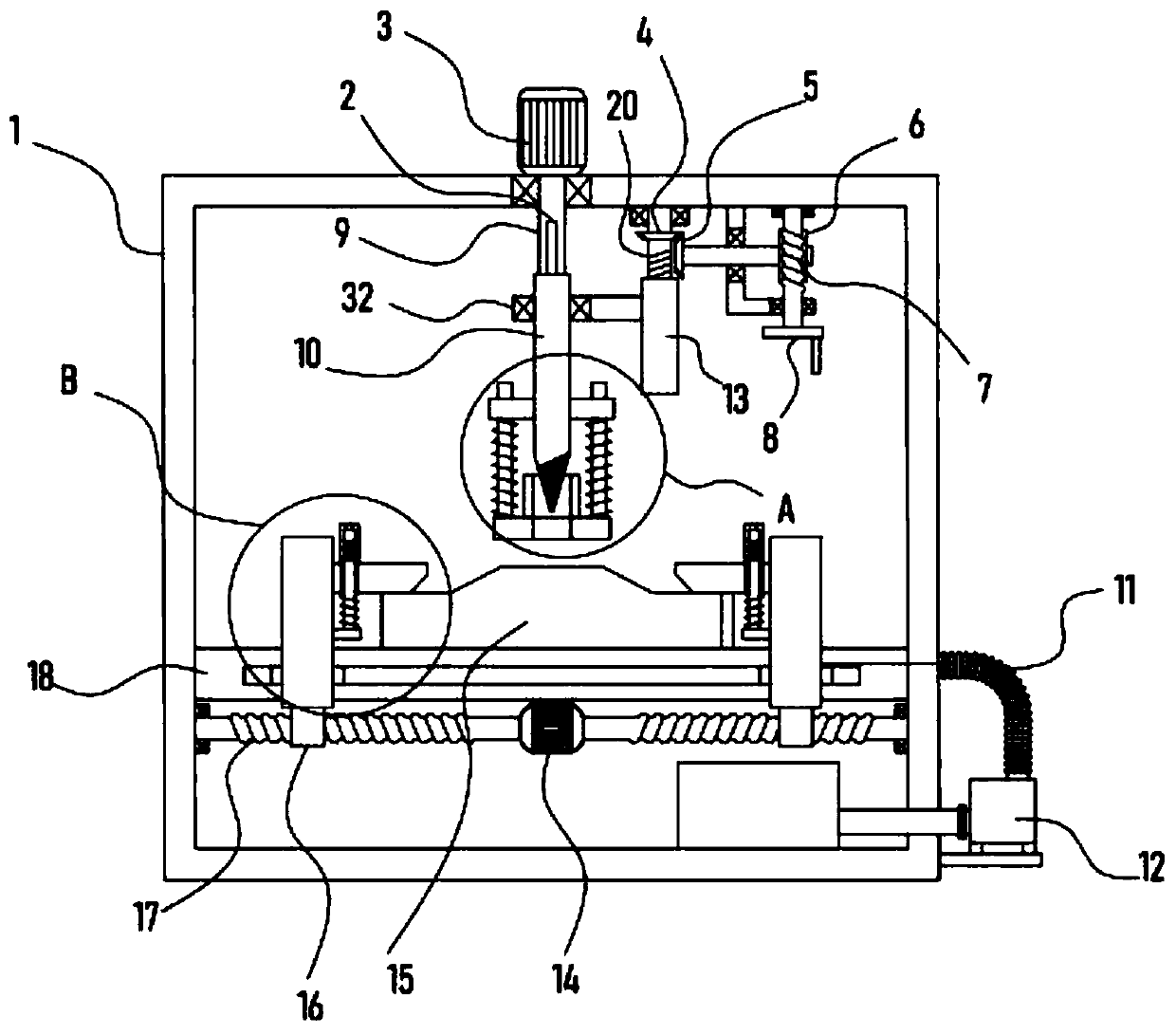

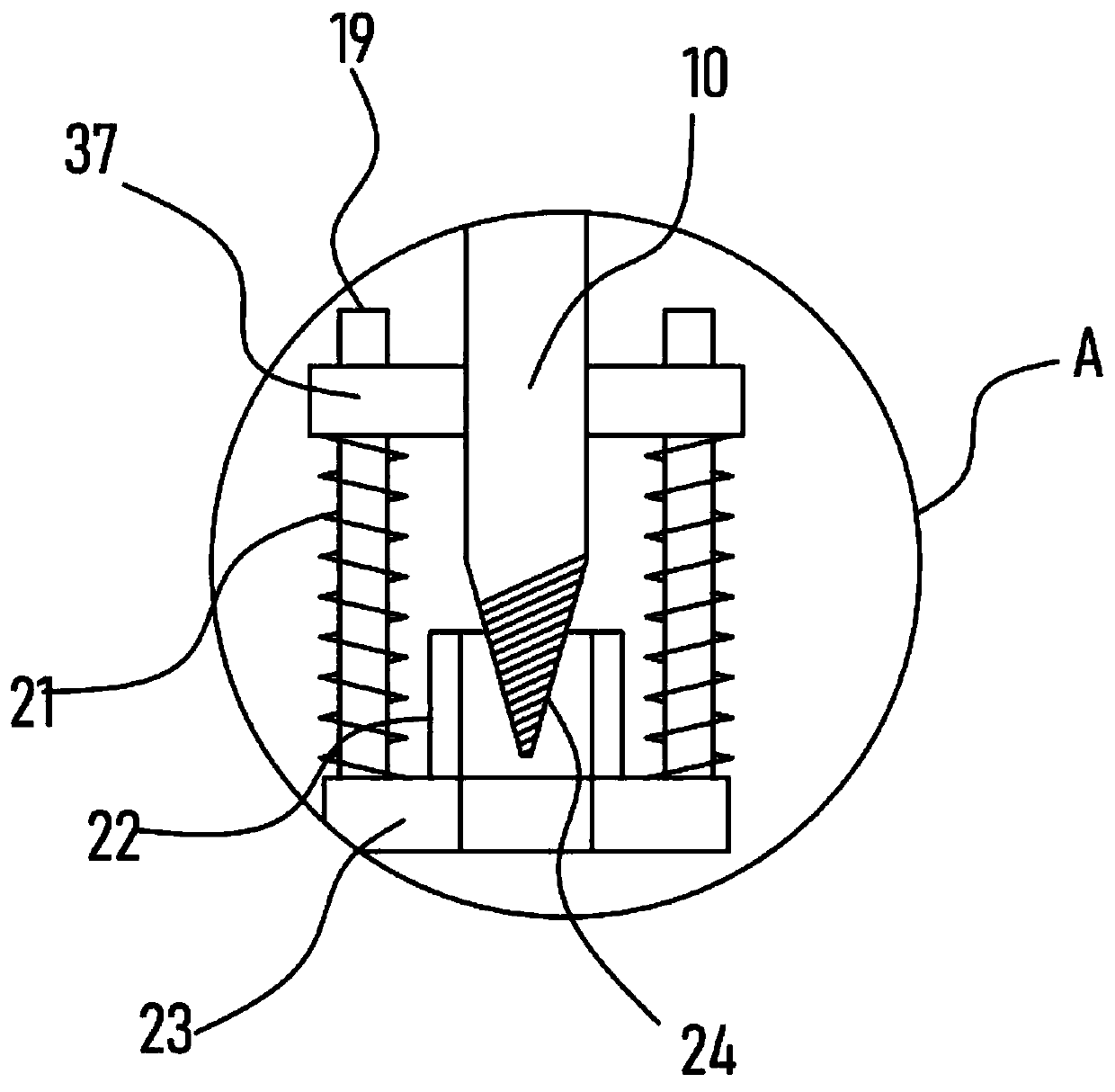

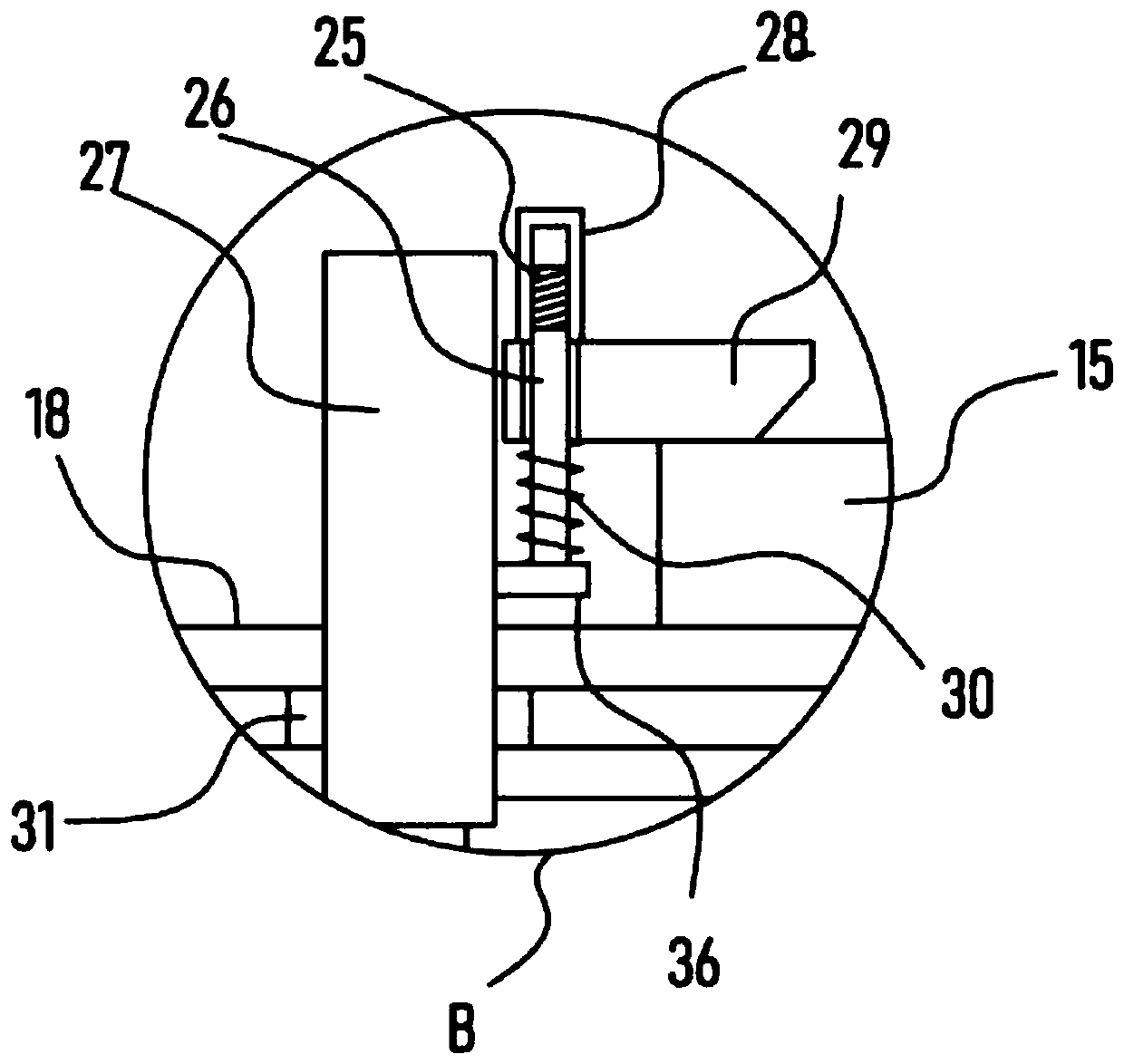

[0025] see Figure 1-4 , a device for processing holes for automobile motors, comprising a support frame 1, a bearing plate 18 is fixedly installed horizontally in the support frame 1, a biaxial motor 14 is fixed on the bottom of the support plate 18, and the biaxial motor 14 is driven and connected to the loading plate. 18 is a slidingly connected opposing translation mechanism, the opposing translation mechanism is provided with a pair of locking mechanisms for clamping and fixing the motor end cover 15, a drive motor 3 is fixed on the top of the support frame 1, and the drive motor 3 The drill bit 24 that is used to drill the motor end cover 15 is connected by a transmission mechanism, and the drill bit 24 is provided with an elastic support mechanism outside, and the support frame 1 is provided with a lifting mechanism for adjusting the lift of the drill bit 24. The support frame 1 There is a dust collection mechanism on it.

[0026] When the motor end cover 15 is drillin...

Embodiment 2

[0032] On the basis of Embodiment 1, in addition, the transmission mechanism of the device includes a transmission bar 2 coaxially fixed with the output shaft of the drive motor 3, and the upper sliding sleeve of the transmission bar 2 is provided with a threaded sleeve 10 fixed to the drill bit 24 at the lower end. The side wall of the rotating shaft 9 is fixed with a transmission bar 2 slidably embedded in the inner wall of the threaded sleeve 10, and the driving motor 3 is set to drive the rotating shaft 9 to rotate, and the rotating shaft 9 drives the threaded sleeve 10 to rotate through the transmission bar 2. When the drill bit 24 rotates thereupon, the lifting mechanism drives the drill bit 24 to move down, so as to realize the perforation effect to the motor end cover 15.

[0033] Specifically, the lifting mechanism includes a lifting plate 32 pivotally connected to the threaded sleeve 10. A vertically arranged threaded sleeve I13 is fixed on the lifting plate 32. The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com