Motor shell cleaning equipment for industrial motor machining

A technology for industrial motors and cleaning equipment, which is applied in the direction of cleaning methods using tools, cleaning methods using liquids, cleaning methods and utensils, etc., can solve the problems of accumulation of dust and dirt, affecting the normal use of the motor, and inconvenient cleaning of the motor casing. It can achieve the effect of good cleaning effect and convenient cleaning of the motor casing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

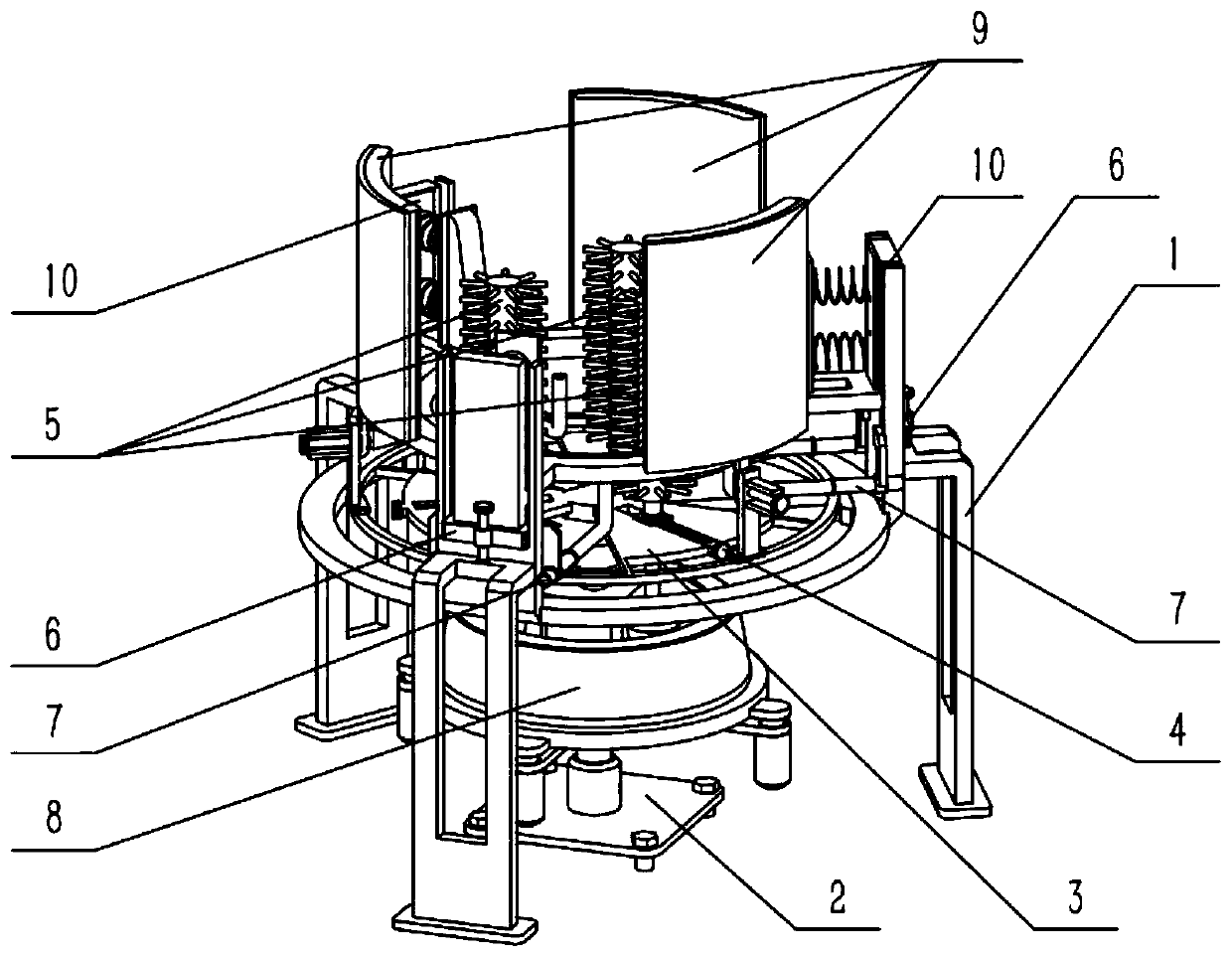

[0040] Combine below Figure 1-14 Describe this embodiment, a motor housing cleaning equipment for industrial motor processing, including a main frame 1 and a positioning structure 10, the positioning structure 10 is provided with three, and the three positioning structures 10 are uniformly arranged on the center of the main frame 1 in the axial direction In the upper part, the motor shell cleaning equipment for industrial motor processing also includes a bottom support mechanism 2, a drive mechanism 3, a radius adjustment mechanism 4, a cleaning structure 5, a connecting frame 6, a water spray pipe 7, a friction transmission ring seat 8 and an outer wall cleaning structure 9 , the lower end of the bottom supporting mechanism 2 is fixedly connected to the ground, the lower end of the driving mechanism 3 is fixedly connected to the bottom supporting mechanism 2, and its upper end is slidably connected to the center of the upper part of the main body frame 1. The radius adjustmen...

specific Embodiment approach 2

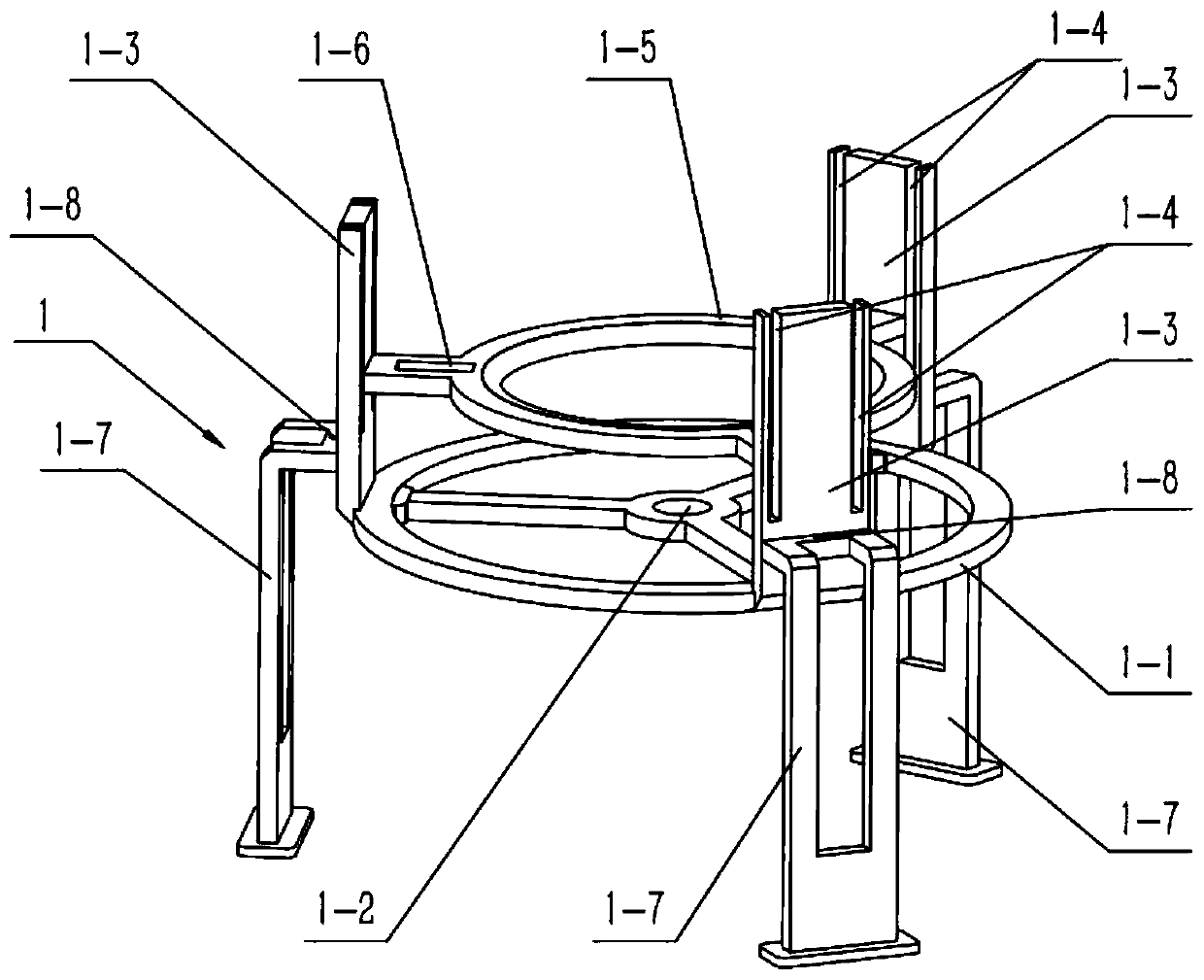

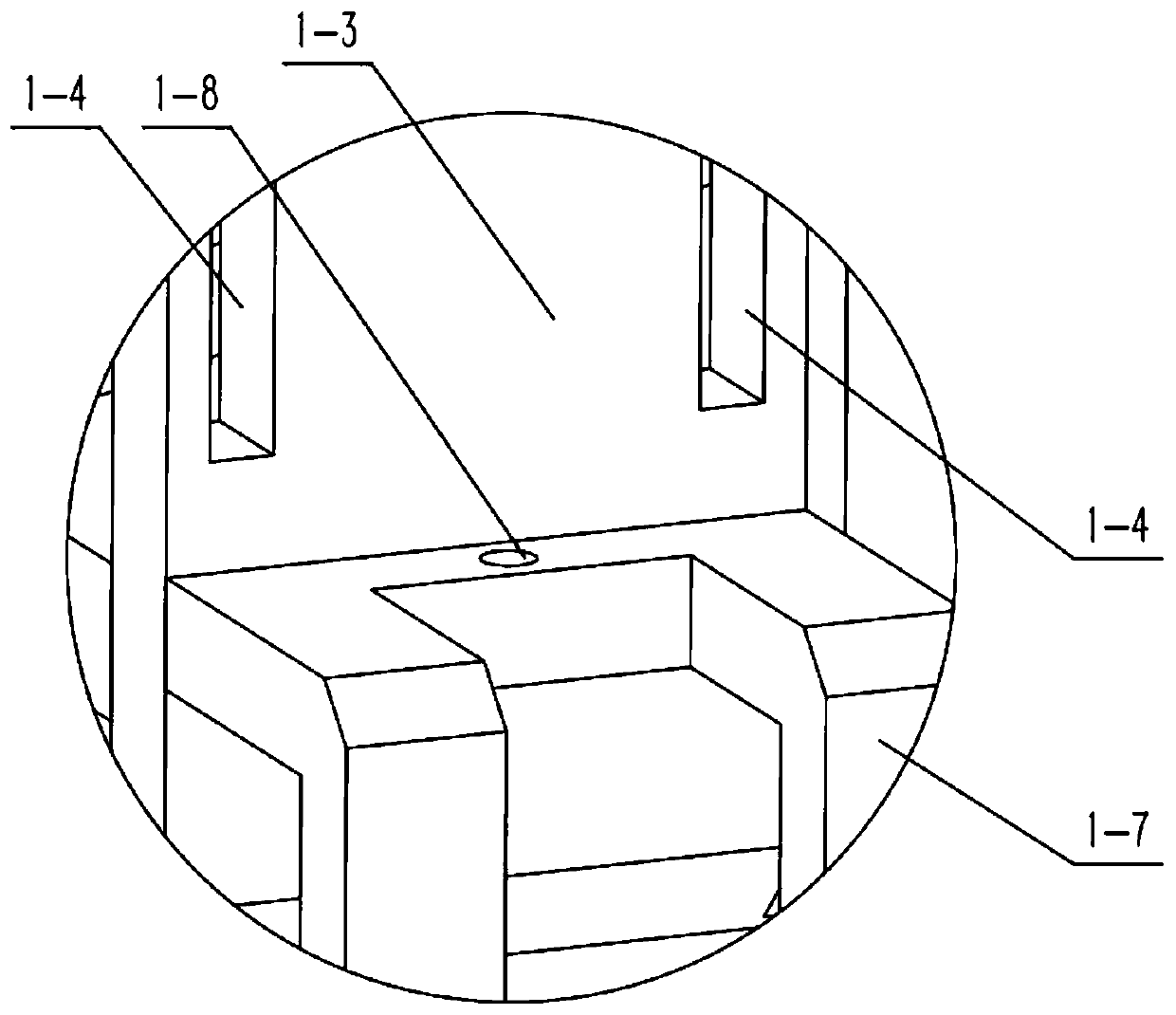

[0043] Combine below Figure 1-14 This embodiment will be described. This embodiment will further describe the first embodiment. The main body frame 1 includes a bottom ring 1-1, a hole I1-2, a vertical plate 1-3, a chute I1-4, an upper ring 1-5, Sliding holes 1-6, legs 1-7 and holes II 1-8, holes I 1-2 are provided in the middle of the bottom ring 1-1, three vertical plates 1-3 are provided, and three vertical plates 1- 3. The circumferential direction is evenly and fixedly connected to the bottom ring 1-1, and two chute I1-4 are symmetrically arranged on each vertical plate 1-3, and the upper ring 1-5 is fixedly connected to the three Between the vertical boards 1-3, three sliding holes 1-6 are evenly arranged in the peripheral direction of the sides, and three supporting legs 1-7 are provided, and the three supporting legs 1-7 are respectively fixedly connected to the three vertical On the board 1-3, a hole II1-8 is provided at the center of the upper part of each leg 1-7;...

specific Embodiment approach 3

[0046] Combine below Figure 1-14 Describe this embodiment, this embodiment will further explain the first embodiment, the bottom support mechanism 2 includes a bottom plate 2-1, a hydraulic rod 2-2, a cross support plate 2-3, a placement cylinder 2-4 and an electric telescopic rod 2 -5, the hydraulic rod 2-2 is fixedly connected to the bottom plate 2-1, the cross support plate 2-3 is fixedly connected to the upper end of the hydraulic rod 2-2, and the placement cylinder 2-4 is set There are four, four placement tubes 2-4 are respectively fixedly connected to the four ends of the cross support plate 2-3, and each electric telescopic rod 2-5 is provided with an electric telescopic rod 2-5;

[0047] The lower end of the driving mechanism 3 is fixedly connected to the middle part of the upper end of the cross support plate 2-3, the lower end of the friction transmission ring seat 8 is fixedly connected to a base 8-1, and the base 8-1 is fixedly connected to the The upper ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com