Plastic package motor for washing machine

A technology for plastic-encapsulating motors and washing machines, applied in electromechanical devices, electrical components, electric components, etc., can solve the problems of short lifespan of washing machines, short lifespan of motors, water resistance, corrosion resistance, low humidity resistance, etc., achieve small deformation, The effect of reducing the contact area and ensuring the bearing degree and waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

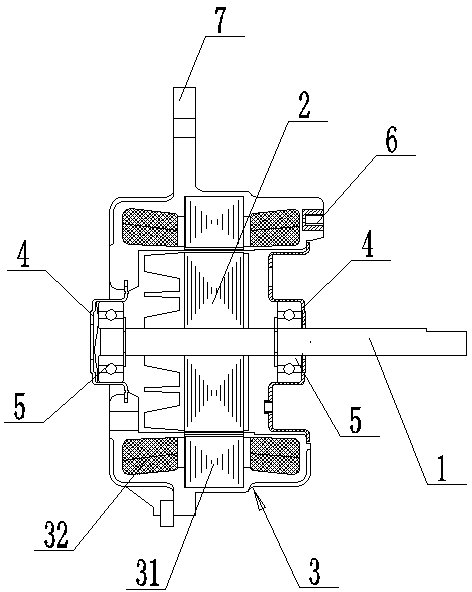

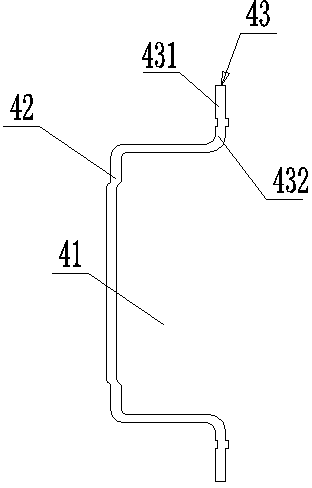

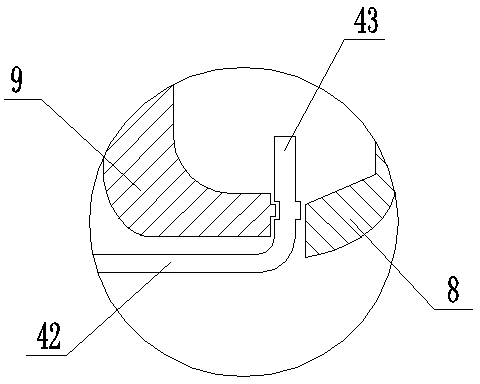

[0023] Embodiment one: according to Figure 1-2 As shown, a plastic-sealed motor for a washing machine includes a rotating shaft 1, a rotor assembly 2, a plastic-sealed stator assembly 3 and an end cover 4. The plastic-sealed stator assembly 3 includes a stator core 31, a stator winding 32 and an injection molded casing. The rotor assembly 2 is installed on the shaft Above 1, the plastic-sealed stator assembly 3 is nested outside the rotor assembly 2, and the two ends of the plastic-sealed stator assembly 3 are equipped with end covers 4, the end cover 4 includes a front end cover and a rear end cover, and a bearing chamber 41 is installed in the bearing chamber. 5, its bearing 5 is a ball bearing.

[0024] The plastic-sealed stator assembly 3 and the rear end cover are molded and sealed into an integrated plastic-sealed stator by molding with a plastic sealing material mold, which effectively ensures the coaxiality of the rear end cover bearing chamber 5 and the inner diamete...

Embodiment 2

[0027] Embodiment two: according to Figure 5-6 As shown, the difference from the above embodiment is that the bearings 5 in the front end cover and the rear end cover are oil-impregnated bearings, and both the front end cover and the rear end cover are provided with bearing clips 44 for installing the oil-impregnated bearings. Compared with ball bearings, oil-impregnated bearings have the advantages of low cost, vibration absorption, and low noise, thereby reducing the noise generated when the motor is running.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com