Multi-axial electric machinery process equipment

A technology of linear motors and processing equipment, applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of bulkiness, equipment cost increase, pillar defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

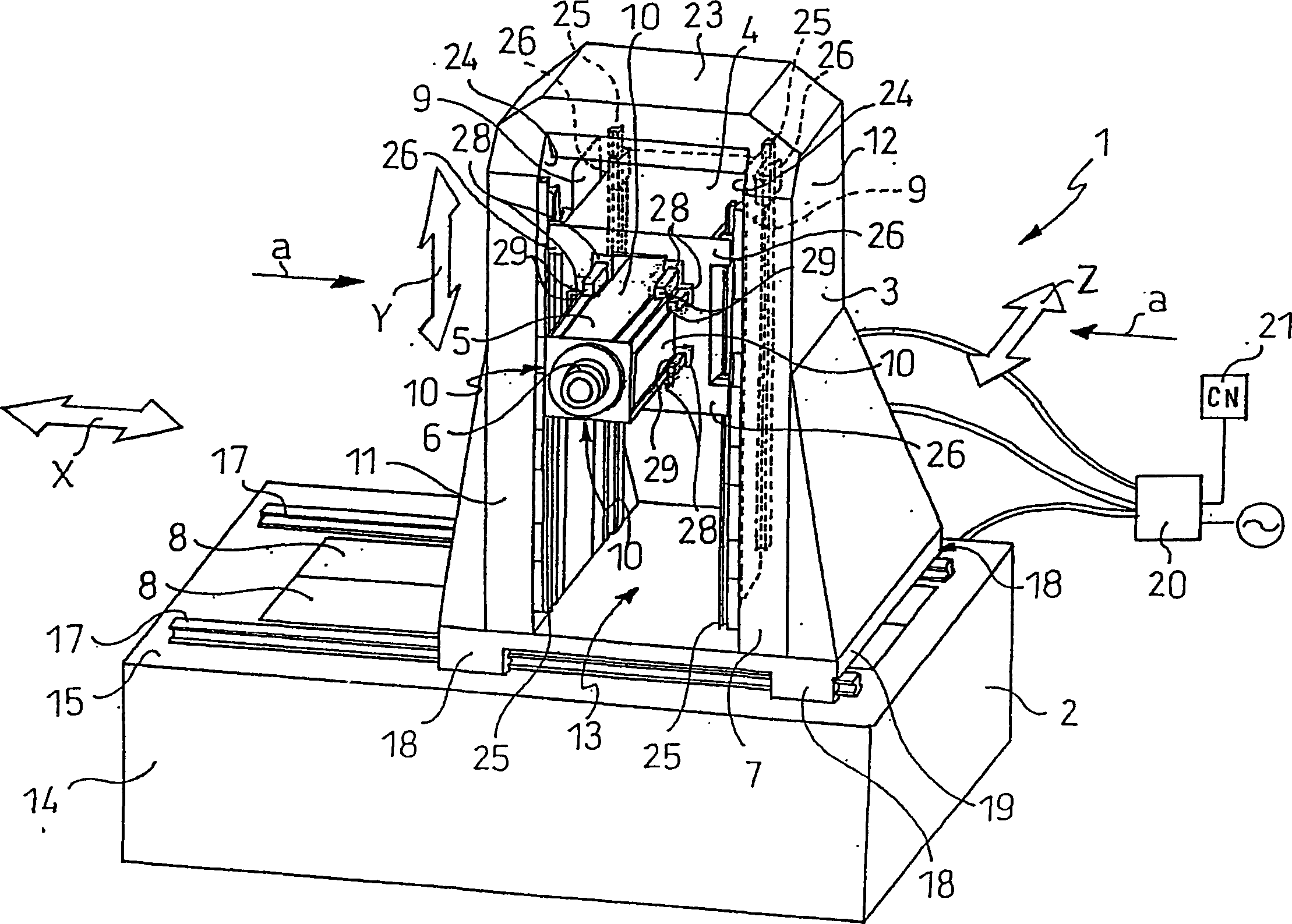

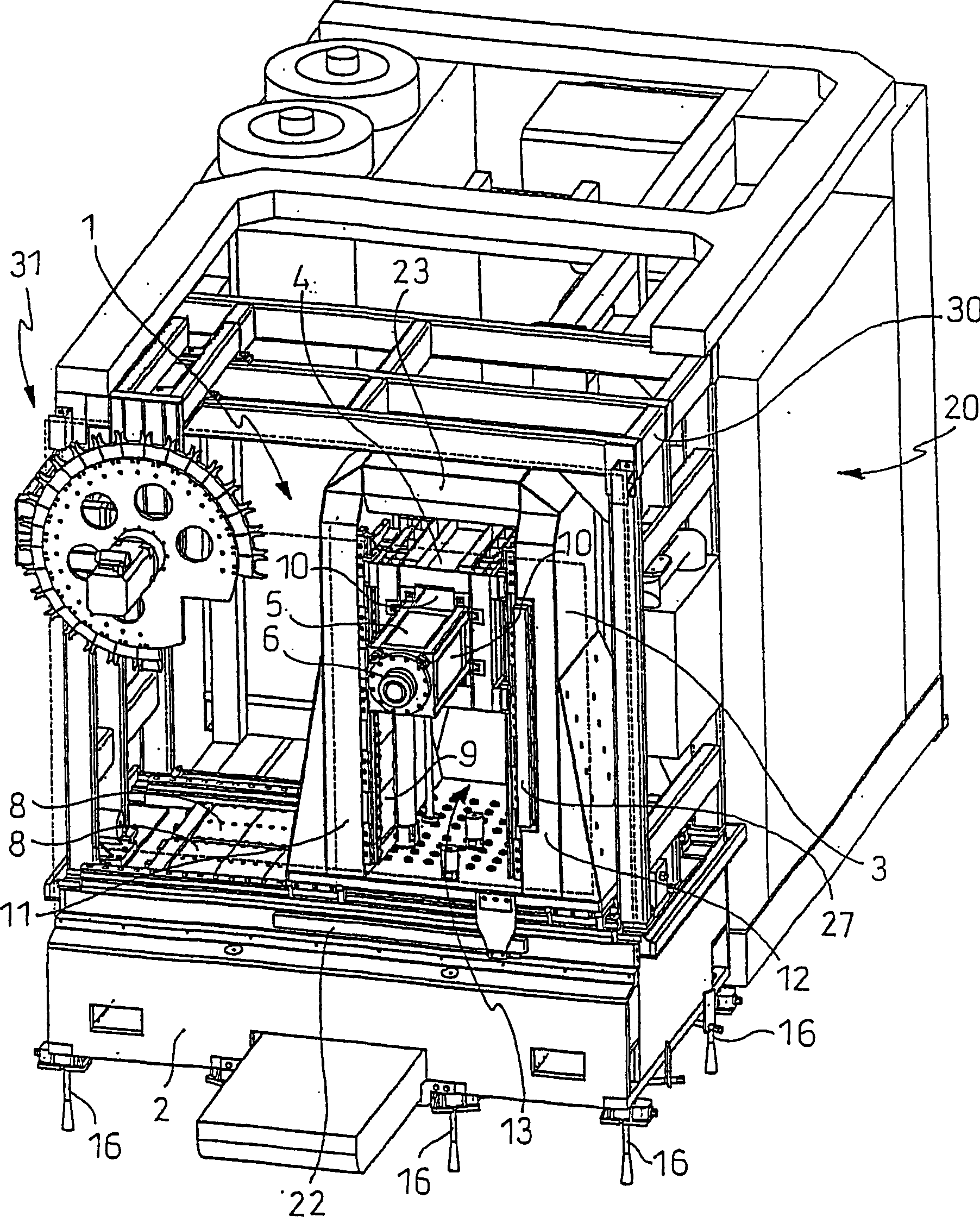

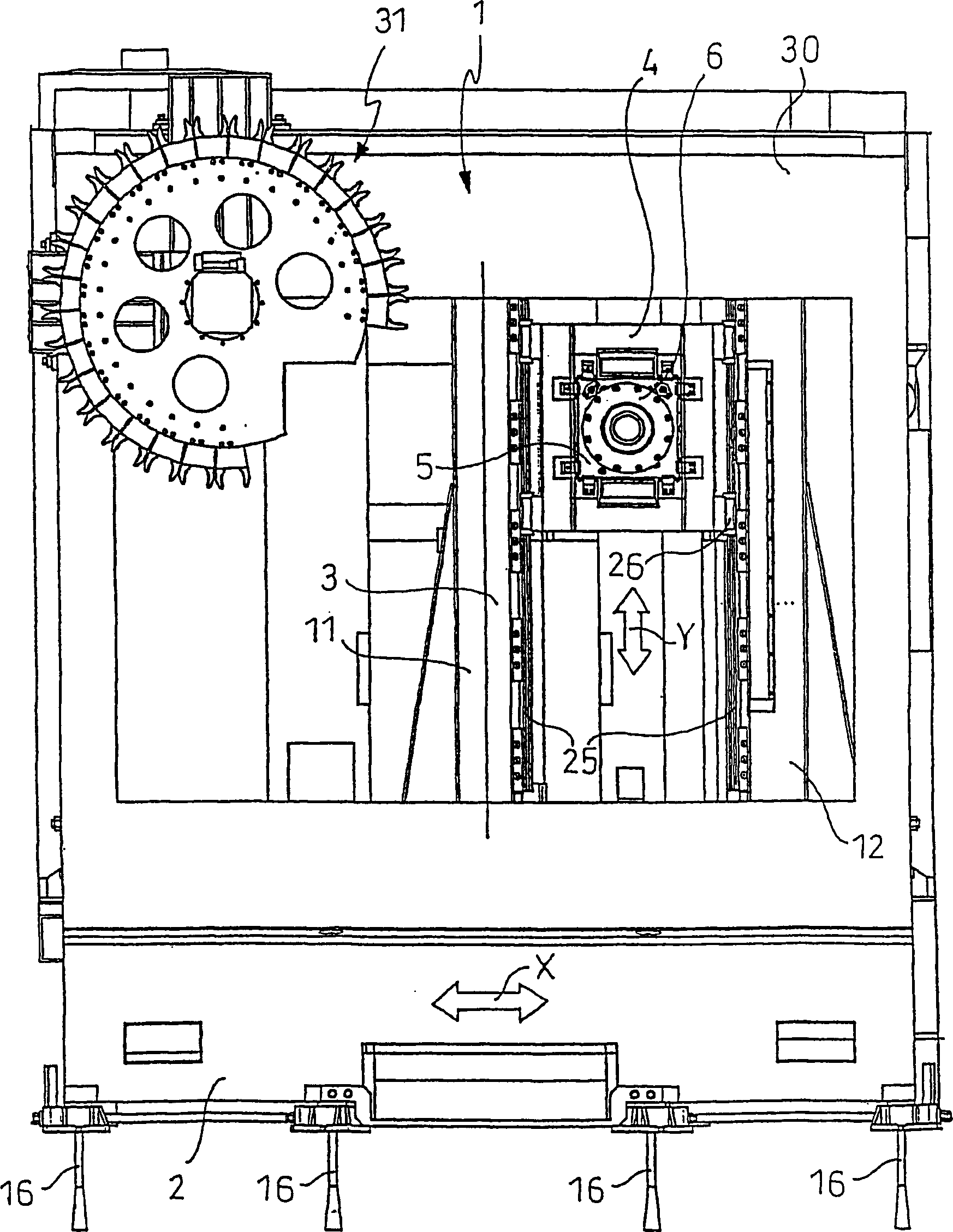

[0017] Referring to the above-mentioned drawings, the processing equipment is generally indicated as 1 . The processing device 1 comprises a bed 2 supporting at least one column 3 on which at least one saddle 4 is slidable. In said saddle mount 4 there is a main sliding mount 5 adapted to support a mandrel 6 for moving the equipment.

[0018] The bed 2 forms at least one first axis (X) arranged longitudinally along the bed 2 . For example, the above-mentioned first axis (X) may be arranged horizontally. Said at least one strut 3 is operatively connected to said first axis (X) so that the bed supports it with only one of its ends 7 and guides it along said first axis (X). At least one strut 3 protrudes from the bed 2 forming a second axis (Y). For example, the second axis (Y) is arranged at right angles to the first axis (X), specifically vertically. At least one saddle 4 is supported on at least one strut 3 so that it can be guided along said second axis (Y). The bend of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com