Astaxanthin freeze-dried powder and preparation method thereof

A technology of astaxanthin and freeze-dried powder, which is applied in the direction of freeze-drying transportation, powder transportation, pharmaceutical formulations, etc., can solve the problems of large loss of astaxanthin activity, poor water solubility, poor shape-forming effect, etc., and achieve astaxanthin activity High degree of retention and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

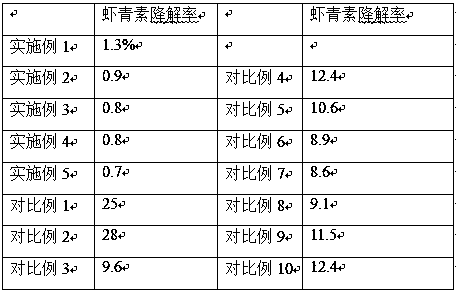

Examples

Embodiment 1

[0040] A preparation method of astaxanthin freeze-dried powder, comprising the steps of:

[0041] 1) Mix fatty acid glycerides, lecithin, and tocopherol according to 3.6:1:1 to make an oil solution;

[0042] 2) Dissolve 1 kg of astaxanthin ester in 5.6 L of oil solution at 40°C to obtain astaxanthin ester solution;

[0043] 3) Add 4.0L of chitosan solution with a mass concentration of 50% to the astaxanthin ester solution obtained in step 2), and keep the temperature at 42°C for 30 minutes;

[0044] 4) Add Tween 80 to the astaxanthin ester-chitosan solution prepared in step 3) at 60°C, then add pH 7.0 phosphate buffer solution pre-dissolved with ethylenediaminetetraacetic acid, homogenize at high speed , until the system is uniform, and an emulsion is obtained;

[0045] 5) 4.5 kg of astaxanthin emulsion obtained in step 4) was added with 88 kg of excipient mannitol, stirred evenly, and freeze-dried to obtain astaxanthin freeze-dried powder.

Embodiment 2

[0047] 1) Mix fatty acid glycerides and lecithin at a ratio of 4.5:1 to make an oil solution;

[0048] 2) Dissolve 1kg of astaxanthin ester extracted from Haematococcus cells in 5.6L oil solution at 55°C to obtain astaxanthin ester solution;

[0049] 3) Add 4.0L of chitosan solution with a mass concentration of 32% to the astaxanthin ester solution obtained in step 2), and keep the temperature at 52°C for more than 30 minutes;

[0050] 4) Add polyglycerol ester to the astaxanthin ester-chitosan solution prepared in step 3) at 55°C, then add ascorbic acid pre-dissolved pH 7.0 phosphate buffer solution, homogenize at high speed until the system is uniform , to obtain an emulsion;

[0051] 5) Take 1.5 kg of astaxanthin emulsion obtained in step 4), add 85 kg of excipient mannitol, stir evenly, and freeze-dry to obtain astaxanthin freeze-dried powder.

Embodiment 3

[0053] 1) Mix fatty acid glycerides and lecithin at a ratio of 4.0:1 to make an oil solution;

[0054] 2) 1kg of astaxanthin ester extracted from Haematococcus cells was dissolved in 5.6L oil solution at 20°C to obtain astaxanthin ester solution;

[0055] 3) Add 4.0L of chitosan solution with a mass concentration of 45% to the astaxanthin ester solution obtained in step 2), and keep the temperature at 50°C for more than 30 minutes;

[0056] 4) Add polyglycerol ester to the astaxanthin ester-chitosan solution prepared in step 3) at 58°C, then add phosphate buffer solution, homogenize at high speed until the system is uniform, and obtain an emulsion;

[0057] 5) Add 6 kg of astaxanthin emulsion obtained in step 4), add 90 kg of excipient mannitol, stir evenly, freeze-dry to obtain astaxanthin freeze-dried powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com